Online extraction and dephenolization method of coal tar wastewater

A technology for coal tar and dephenolization, applied in chemical instruments and methods, water pollutants, multi-stage treatment of water/sewage, etc. The effect of eliminating secondary pollution, simplifying process steps and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

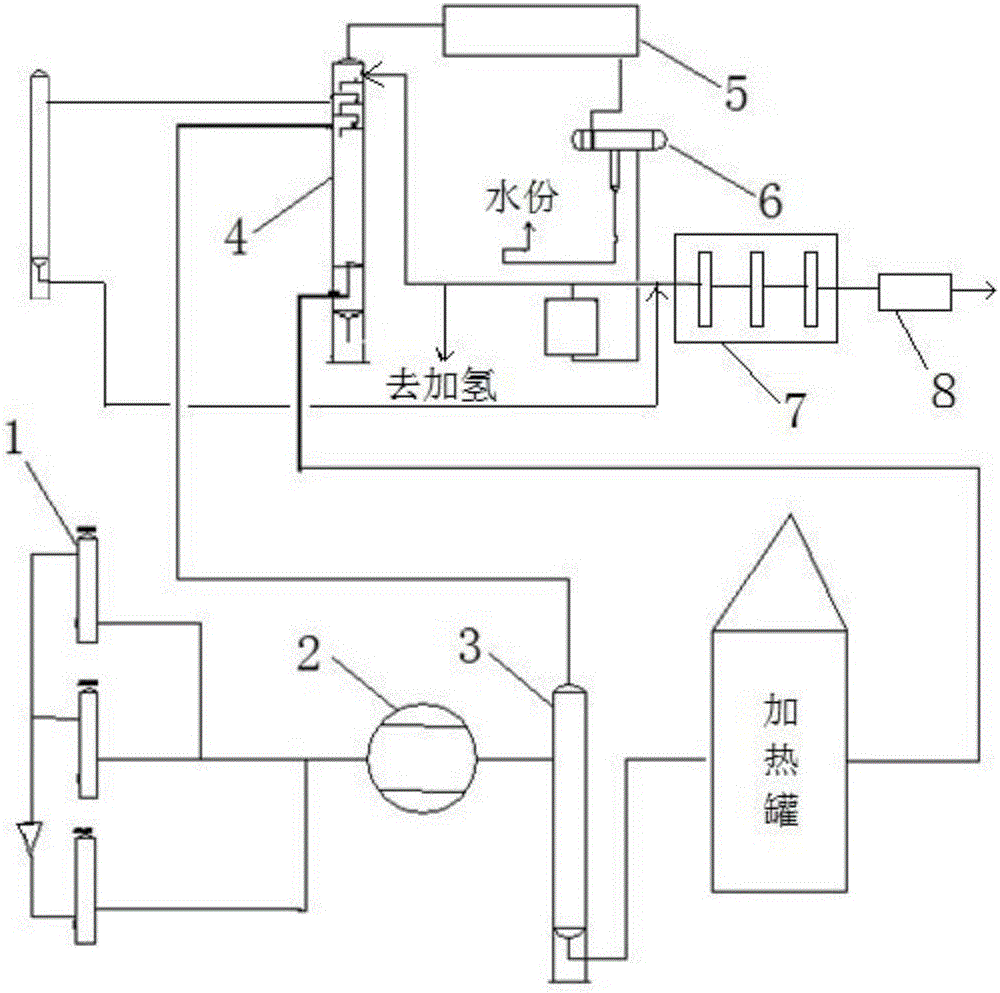

Image

Examples

Embodiment 1

[0037] On-line extraction and dephenolization of coal tar wastewater includes the following steps:

[0038] Step 1, coal tar heating and decompression flash evaporation:

[0039] Transport the hydrated coal tar to the coal tar storage tank. In order to prevent the coal tar oil from delamination, the coal tar storage tank should be equipped with a stirring device and stirred regularly. For the water that is clearly stratified in the upper part of the tank, it is discharged to the coal tar oil water storage tank through the water cutout. The water in the oil-water storage tank is mixed with coal tar before being pumped into the heat exchanger during normal production. Heat the water-containing coal tar through a heat exchanger until it reaches 120°C, and then enters the coal tar decompression flash tank. Vaporize, release the mixed steam.

[0040] Step 2, online extraction and dephenolization:

[0041] The mixed steam is sent to the middle and upper part of the rectification...

Embodiment 2

[0043] On-line extraction and dephenolization of coal tar wastewater includes the following steps:

[0044] Step 1, coal tar heating and decompression flash evaporation:

[0045] Transport the water-containing coal tar to the coal tar storage tank. In order to prevent the coal tar oil from delamination, the coal tar storage tank should be equipped with a high stirring device and stirred regularly. For the water that is clearly stratified in the upper part of the tank, it is discharged to the coal tar oil water storage tank through the water cutout. The water in the oil-water storage tank is mixed with coal tar before being pumped into the heat exchanger during normal production. Heat the water-containing coal tar through a heat exchanger until it reaches 180°C, and then enters the coal tar decompression flash tank. Vaporization, release the mixed steam.

[0046] Step 2, online extraction and dephenolization:

[0047] The mixed steam is sent to the middle and upper part of ...

Embodiment 3

[0049] On-line extraction and dephenolization of coal tar wastewater includes the following steps:

[0050] Step 1, coal tar heating and decompression flash evaporation:

[0051] Transport the water-containing coal tar to the coal tar storage tank. In order to prevent the coal tar oil from delamination, the coal tar storage tank should be equipped with a high stirring device and stirred regularly. For the water that is clearly stratified in the upper part of the tank, it is discharged to the coal tar oil water storage tank through the water cutout. The water in the oil-water storage tank is mixed with coal tar before being pumped into the heat exchanger during normal production. Heat the water-containing coal tar through a heat exchanger until it reaches 150°C, and then enters the coal tar decompression flash tank. Vaporization, release the mixed steam.

[0052] Step 2, online extraction and dephenolization:

[0053] The mixed steam is sent to the middle and upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com