Tee joint hot-melting processing device

A technology of processing equipment and tee pipes, which is applied in metal processing and other directions, can solve problems such as complex processes, difficult manual operations, and low production efficiency, and achieve the effects of convenient and fast operation, reduced labor intensity, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

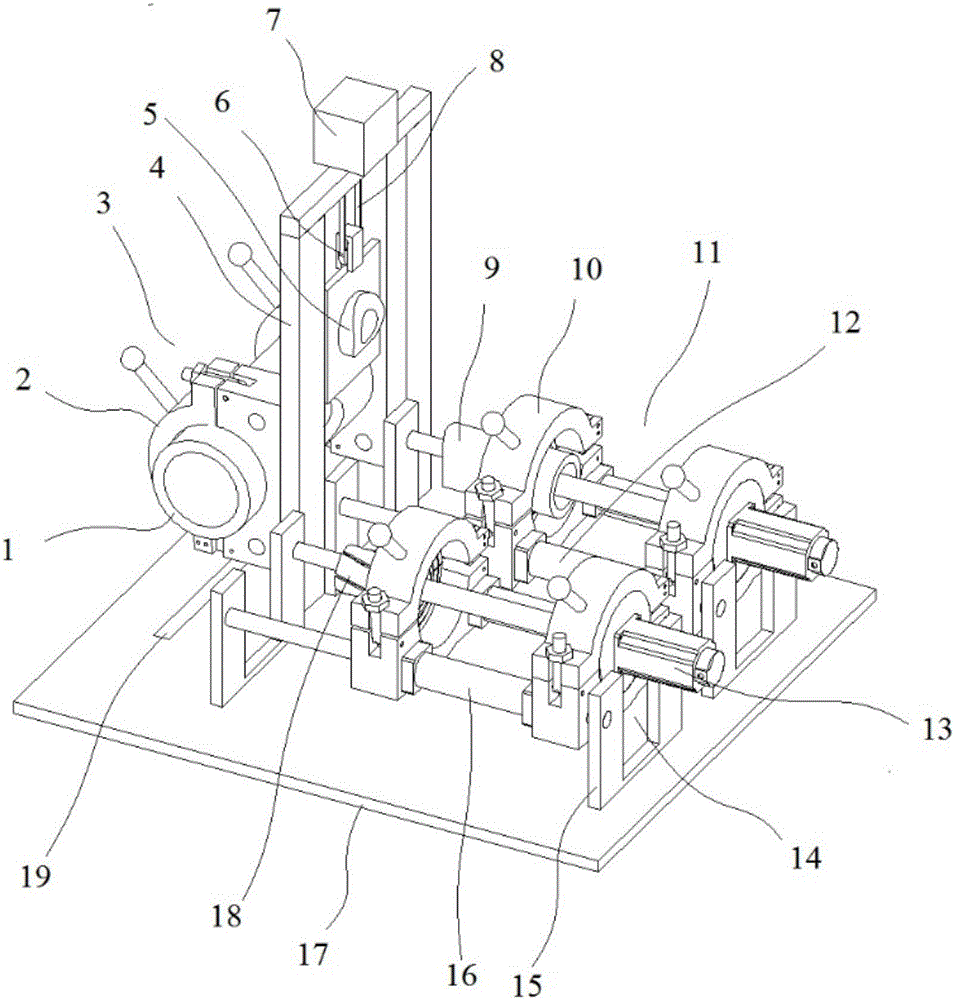

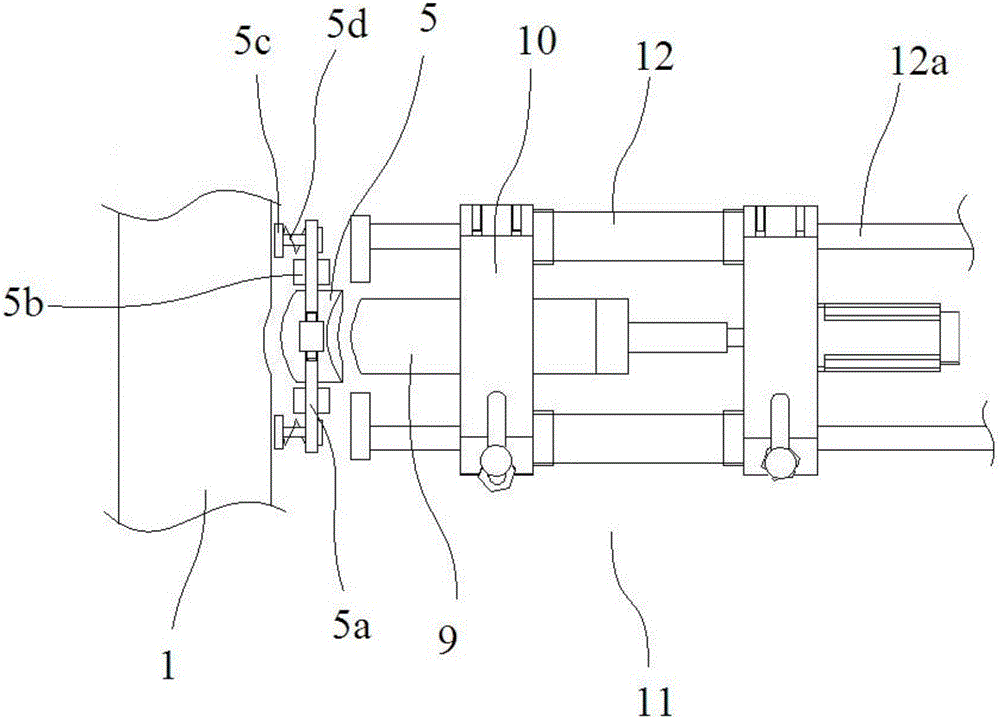

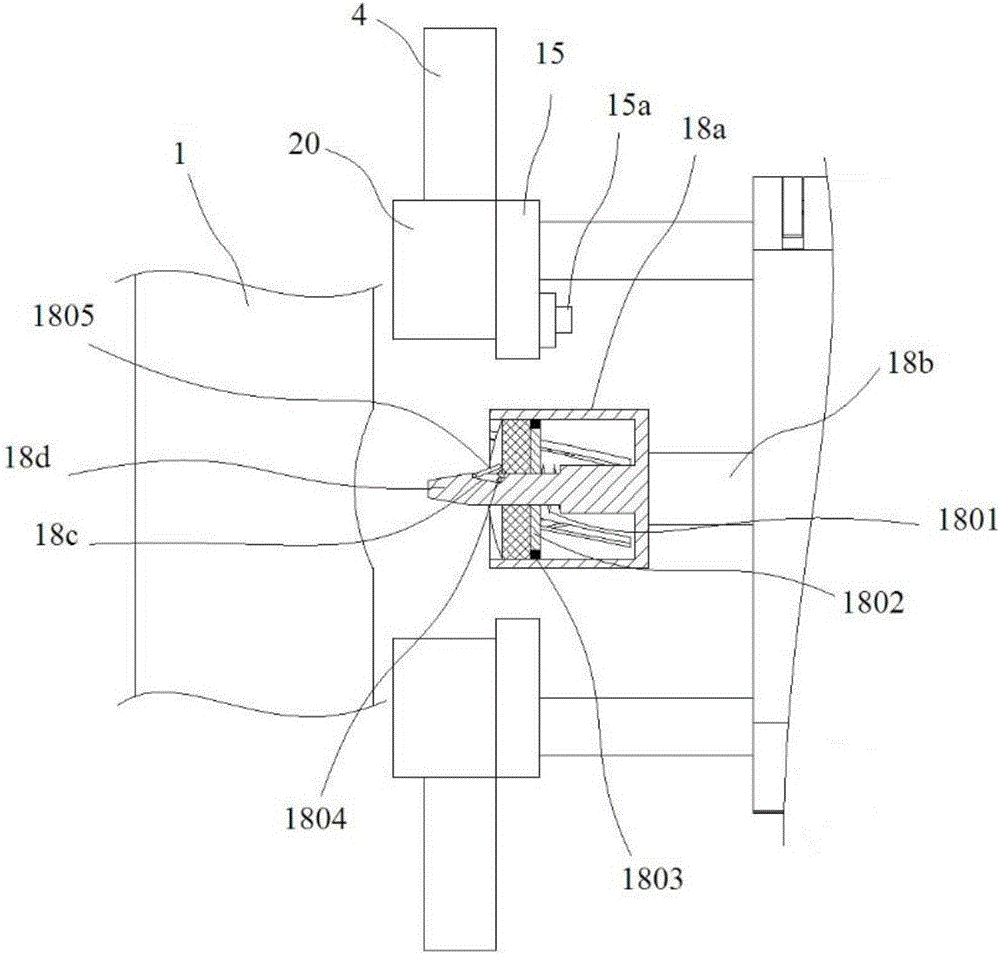

[0020] Such as figure 1 In the shown embodiment, a three-way pipe joint hot-melt processing equipment includes a platform 17 , a main pipe positioning platform 3 , a branch pipe positioning platform 11 and a punching knife translation platform 13 . The stand is provided with two vertical rails 4, and the stand is provided with a chute 19 below the supervisor positioning platform. The supervisor positioning platform can slide along the chute, and the slide of the supervisor positioning platform can be manually slid, or can be connected to a cylinder or Oil cylinder etc. are controlled. The supervisor positioning platform is provided with a supervisor positioning snap ring 2, and the supervisor 1 is horizontally positioned. Two positioning brackets 15 are provided on the platform, and the positioning bracket is positioned at one side of the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com