A simple welding manipulator

A welding manipulator and simple technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that it is difficult to meet the requirements of welding seam flatness, welding quality is difficult to be guaranteed, and the shell of electric welding machine is not grounded and grounded, etc. problems, to achieve the effect of improving working conditions, simple structure, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The following embodiments introduce a simple welding manipulator, but the scope of protection of the present invention is not limited to the following embodiments. All equivalent changes and modifications made according to the content of this specification belong to the technical scope of the patent application of the present invention.

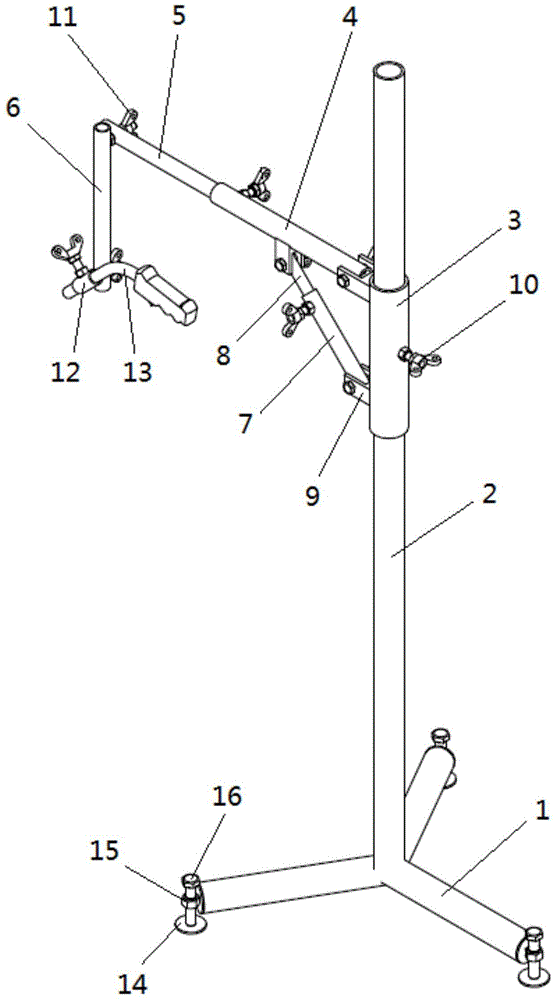

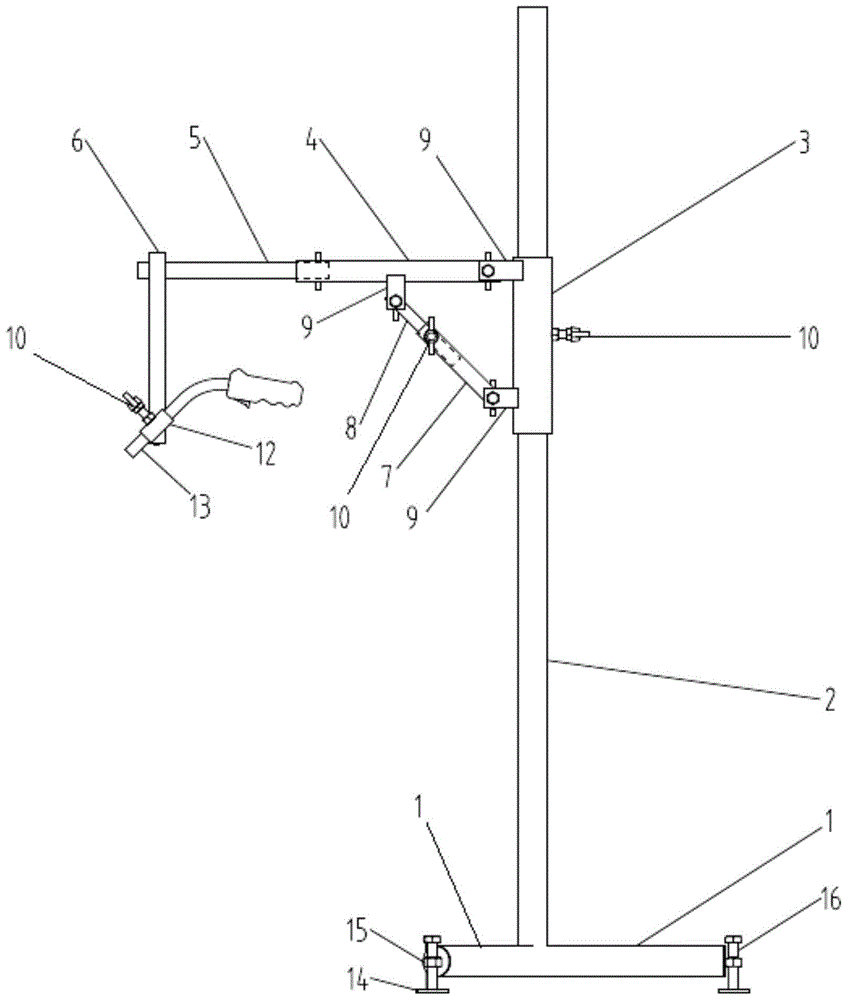

[0028] Please refer to figure 1 with figure 2 , the diagram shows a simple welding manipulator including a base part, a multi-degree-of-freedom manipulator part and a welding torch fixing part. The base part is placed on the ground, the multi-degree-of-freedom mechanical arm part is connected to the base part and can realize vertical up-and-down movement and horizontal turning motion along the base part, and the end of the multi-degree-of-freedom mechanical arm part passes through the multi-degree-of-freedom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com