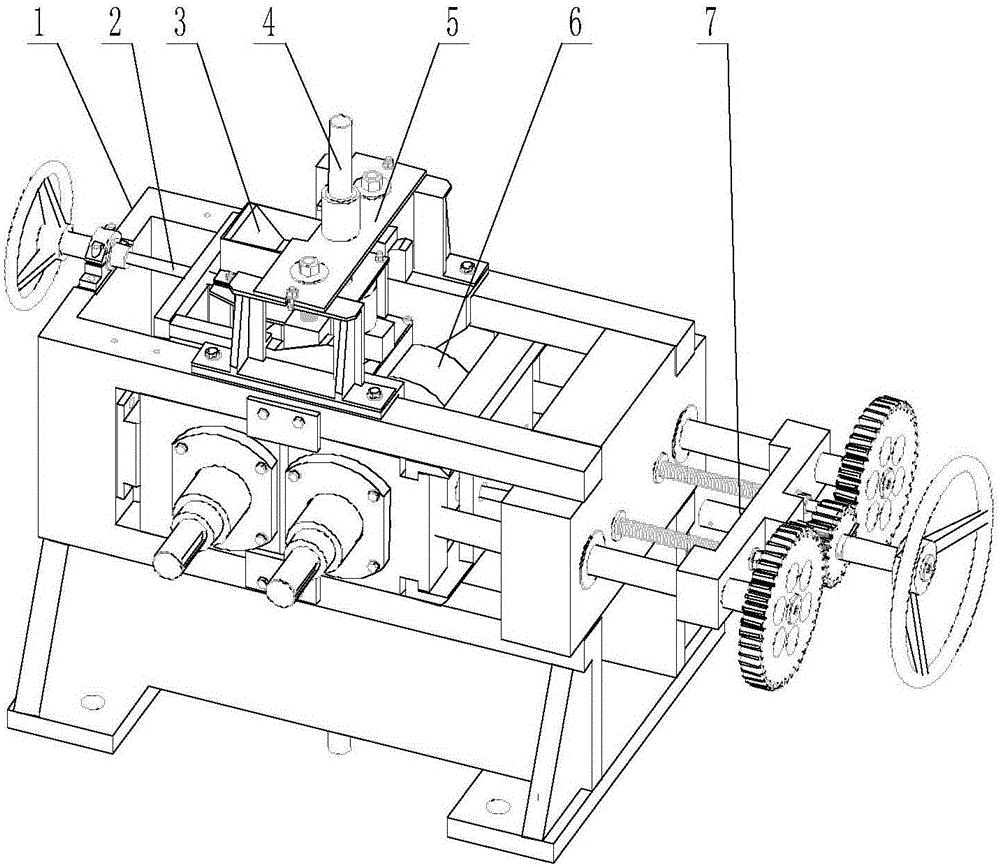

Solid-liquid composite cast rolling machine for dual-metal-layer composite pipe

A bimetal layered, solid-liquid composite technology is applied in the field of bimetal layered composite materials to achieve the effects of ensuring stability, improving pouring efficiency, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

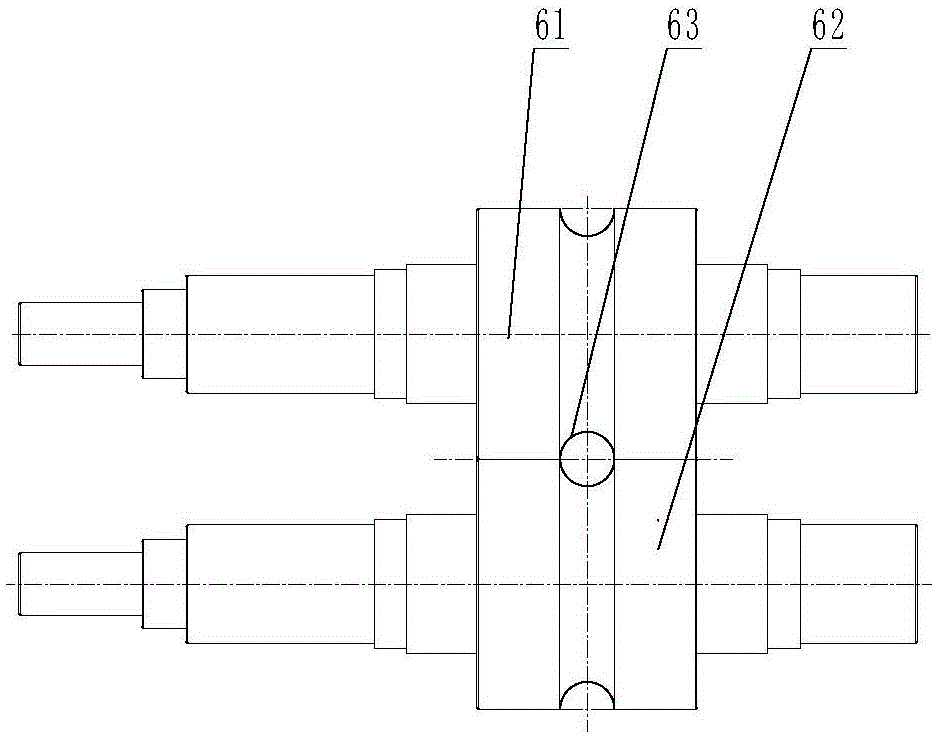

Method used

Image

Examples

Embodiment 1

[0053] Taking the steel / aluminum bimetal layered composite pipe as an example, the equipment of the present invention is used to process and produce the steel / aluminum layered composite pipe, and the outer diameter is selected to be The Q235 seamless steel pipe with a wall thickness of 4mm is used as the metal pipe to be clad 4, and industrial pure aluminum is used as the cladding material to produce a steel / aluminum composite pipe with a cladding metal thickness of 2.5mm.

[0054] 1. First, the outer surface of the Q235 metal pipe 4 to be compounded is treated to remove scale and degrease, so as to make the surface clean;

[0055] 2. Melt the aluminum ingot, heat it to 700°C and keep it warm;

[0056] 3. Use the lifting adjustment device 2 to adjust the pouring unit 3 to a suitable height, turn on the heating device 304, preheat the annular flow distributor 303 to 250°C, set the casting and rolling speed to 1.2m / min, turn on the casting and rolling machine and enter idling s...

Embodiment 2

[0060] Taking the copper / aluminum bimetal layered composite pipe as an example, adopt the equipment of the present invention to process and produce the copper / aluminum layered composite pipe, and select the outer diameter The industrial red copper pipe with a wall thickness of 2mm is used as the metal pipe to be clad 4, and the industrial pure aluminum is used as the cladding material to produce a copper / aluminum composite pipe with a cladding metal thickness of 2mm.

[0061] 1. First, the outer surface of the copper pipe 4 to be composited is treated to remove iron scale and degrease, so as to make the surface clean;

[0062] 2. Melt the aluminum ingot, heat it to 700°C and keep it warm;

[0063] 3. Use the lifting adjustment device 2 to adjust the pouring unit 3 to a suitable height, turn on the heating device 304, preheat the annular flow distributor 303 to 250°C, set the casting and rolling speed to 1.2m / min, turn on the casting and rolling machine and enter idling standb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com