A device and method for preparing semi-solid slurry

A technology of semi-solid slurry and radius, which is applied in the field of semi-solid slurry preparation devices to achieve the effects of low energy consumption, uniform distribution of temperature field and concentration field, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

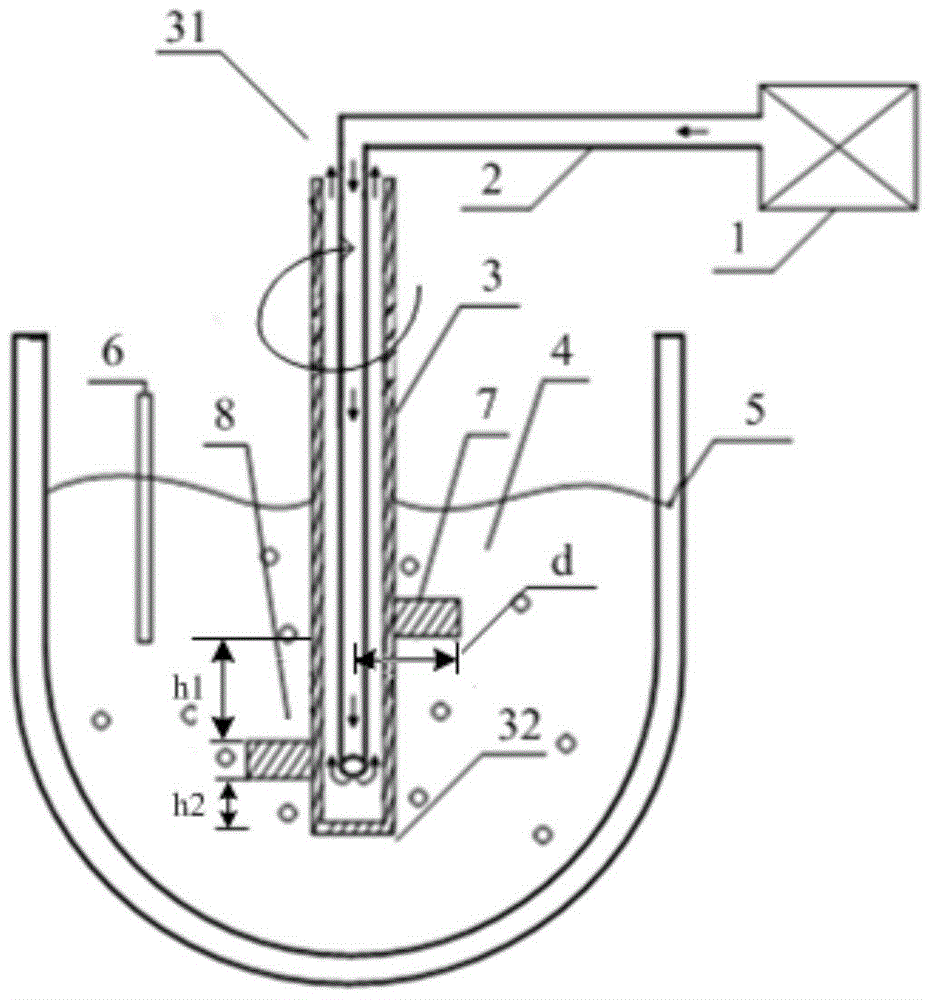

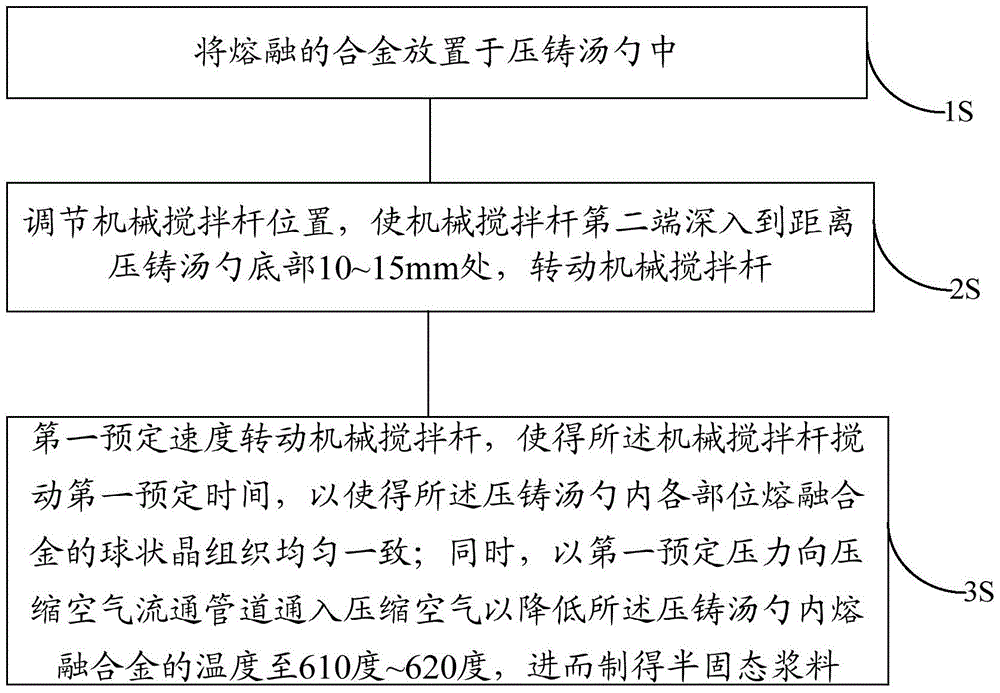

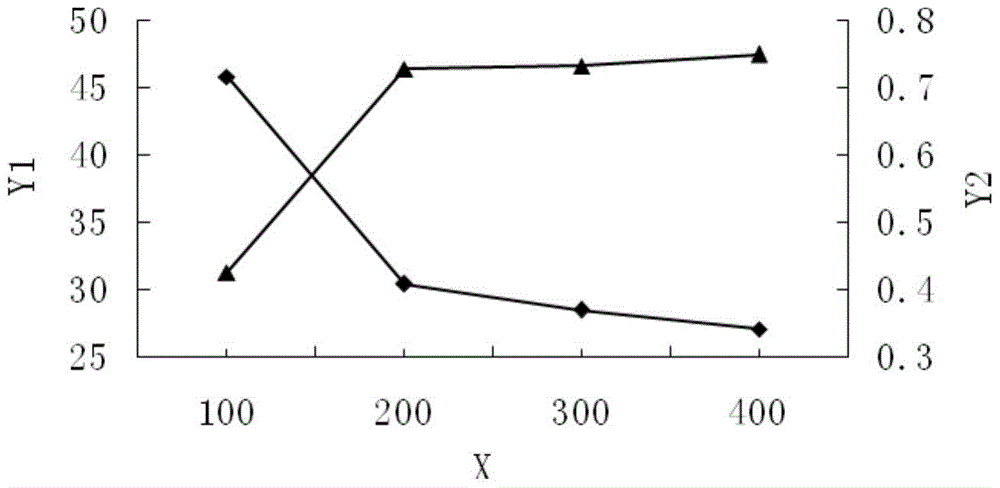

[0062] Place the molten aluminum alloy with a temperature of 670 degrees Celsius in the die-casting spoon, adjust the position of the mechanical stirring rod so that the second end of the mechanical stirring rod is 10mm from the bottom of the spoon, rotate the mechanical stirring rod, and at the same time, the compressed air generator moves toward the bottom of the spoon. The compressed air circulation pipe in the mechanical stirring rod is passed into the compressed air, the pressure of the compressed air is adjusted to 0.4MPa, the rotation speed of the mechanical stirring rod is adjusted to 250 rpm, and the stirring time is 25 seconds, and the corresponding half solid slurry.

Embodiment 2

[0064] Place the molten aluminum alloy with a temperature of 655 degrees Celsius in the die-casting spoon, adjust the position of the mechanical stirring rod so that the second end of the mechanical stirring rod is 13mm from the bottom of the spoon, rotate the mechanical stirring rod, and at the same time the compressed air generator moves to the bottom of the spoon. The compressed air circulation pipe in the mechanical stirring rod is fed with compressed air, the pressure of the compressed air is adjusted to 0.2 MPa, the rotation speed of the mechanical stirring rod is adjusted to 100 rpm, and the stirring time is 30 seconds, and the corresponding half solid slurry.

Embodiment 3

[0066] Place the molten aluminum alloy with a temperature of 685 degrees Celsius in the die-casting spoon, adjust the position of the mechanical stirring rod so that the second end of the mechanical stirring rod is 15mm away from the bottom of the spoon, rotate the mechanical stirring rod, and at the same time the compressed air generator moves toward the bottom of the spoon. The compressed air circulation pipe in the mechanical stirring rod is fed with compressed air, the pressure of the compressed air is adjusted to 0.6MPa, the rotation speed of the mechanical stirring rod is adjusted to 400 rpm, and the stirring time is 20 seconds, and the corresponding half solid slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com