Domestic kitchen garbage smashing machine

A technology of food waste and shredder, which is applied in the direction of grain processing, etc., and can solve the problems of not being able to sufficiently crush food waste or fibrous soft substances, and pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

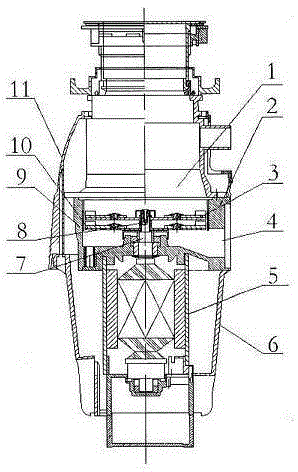

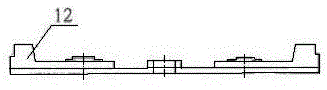

[0009] picture 1 based on invention An embodiment of a structure of a household food waste disposer with multi-layer cutter heads picture , food waste enters the water storage tank (2) through the water storage tank inlet (1), and the water storage tank (2) is equipped with a first-stage cutter head (3) and a final-stage cutter head (10), and food residues and fibrous soft substances pass through the knife After the disc is broken, it is discharged from the outlet (4) of the water storage tank.

[0010] The first-stage cutter head (3) and the last-stage cutter head (10) are fixed on the rotating shaft (7) of the motor (5) through threaded holes, and the first-stage single disc and the last-stage cutter head are separated by a sleeve (8). The structure of the first-stage cutterhead and the last-stage cutterhead is exactly the same. The food waste flows into the water storage tank through the water storage tank inlet, and first passes through the smashing action of the smas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com