Novel steel cylinder surface paint spraying equipment

A technology of spraying equipment and steel cylinders, which is applied in the direction of spraying devices, etc., can solve problems such as difficulties, increased labor intensity of workers, paint splashing, etc., and achieve the effect of compact structure, saving labor intensity of workers, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

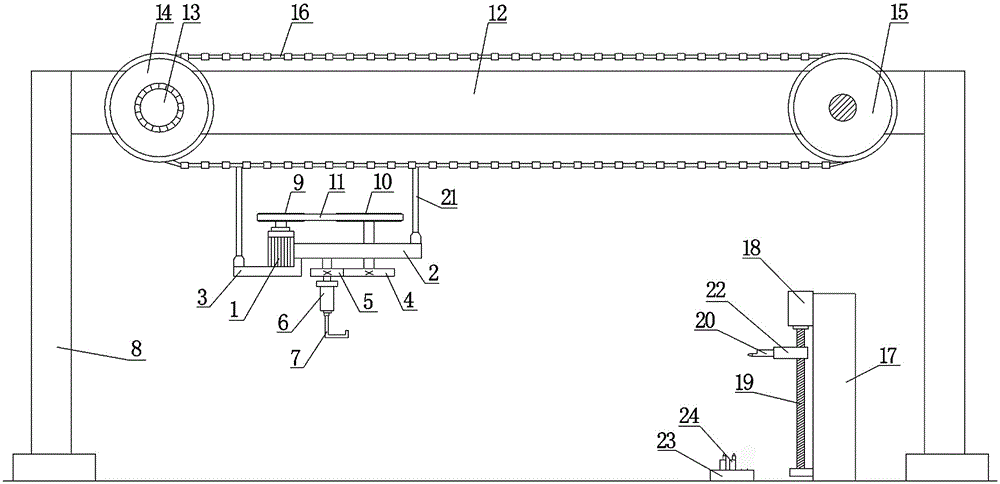

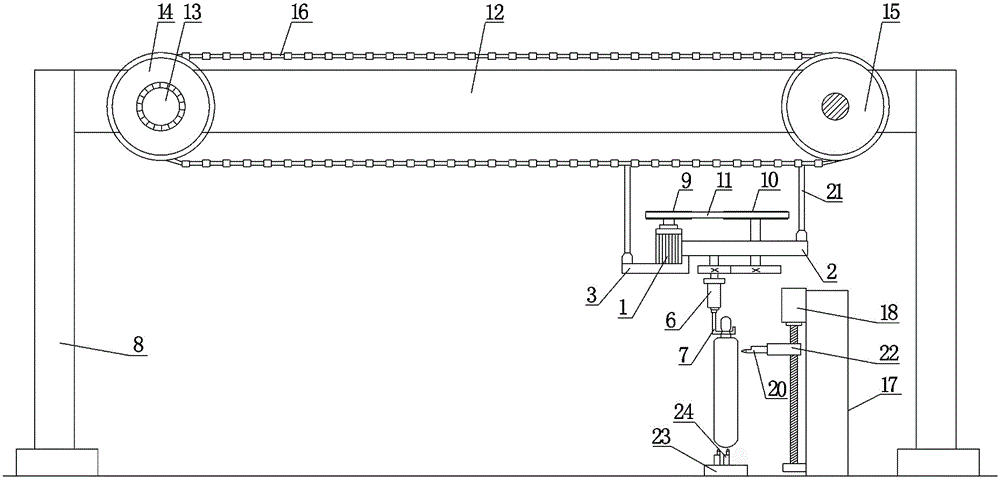

[0014] Such as figure 1 or figure 2 As shown, a new steel cylinder surface painting equipment includes a frame 12, a steel cylinder rotating device, a steel cylinder spraying mechanism, a servo motor A13, and a driving sprocket 14 and a driven sprocket 15 that are installed on the frame 12 by rotating the rotating shaft. A chain 16 is installed between the sprocket 14 and the driven sprocket 15 , and the output end of the servo motor A13 is connected to the rotating shaft of the driving sprocket 14 .

[0015] Such as figure 1 or figure 2 As shown, the steel cylinder rotation device is composed of a servo motor B1, a flat plate 2 and a transmission device. The flat plate 2 is fixed on the chain 16 through a connecting rod 21. An L plate 3 is arranged on the end face of the flat plate 2. The servo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com