New method for separating out and purifying high-purity lysozyme from egg white

A high-efficiency, chromatographic packing technology, applied in the field of high-performance liquid chromatography and active protein preparation, can solve the problems of protein irreversible adsorption and strong hydrophobic interaction, etc., and achieve simple and mature preparation process, easy control and amplification, good selectivity and The effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

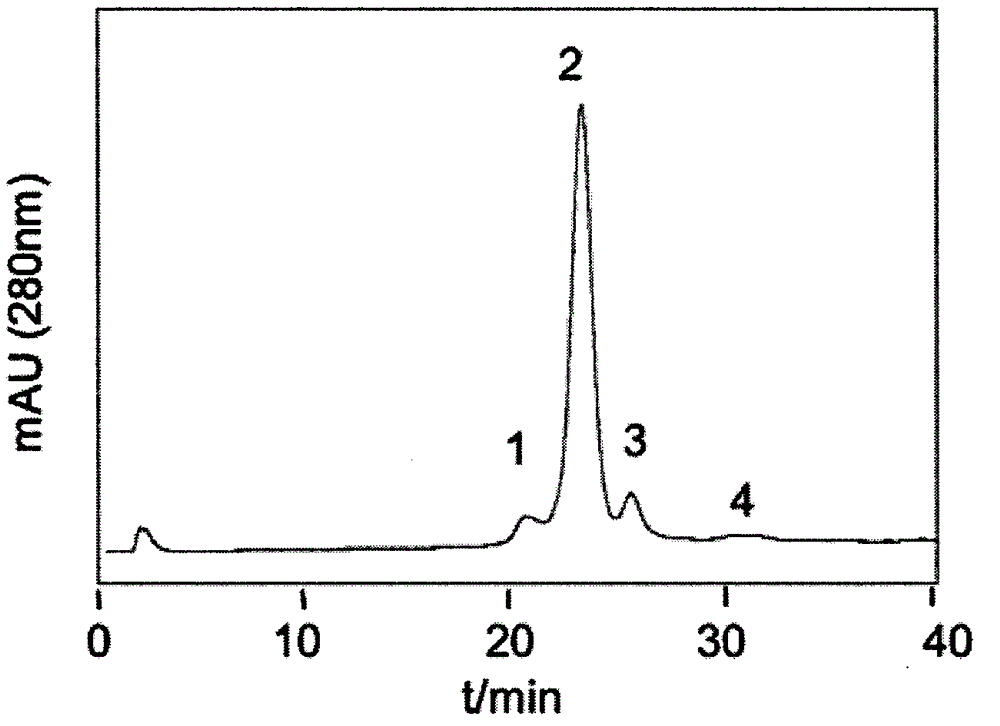

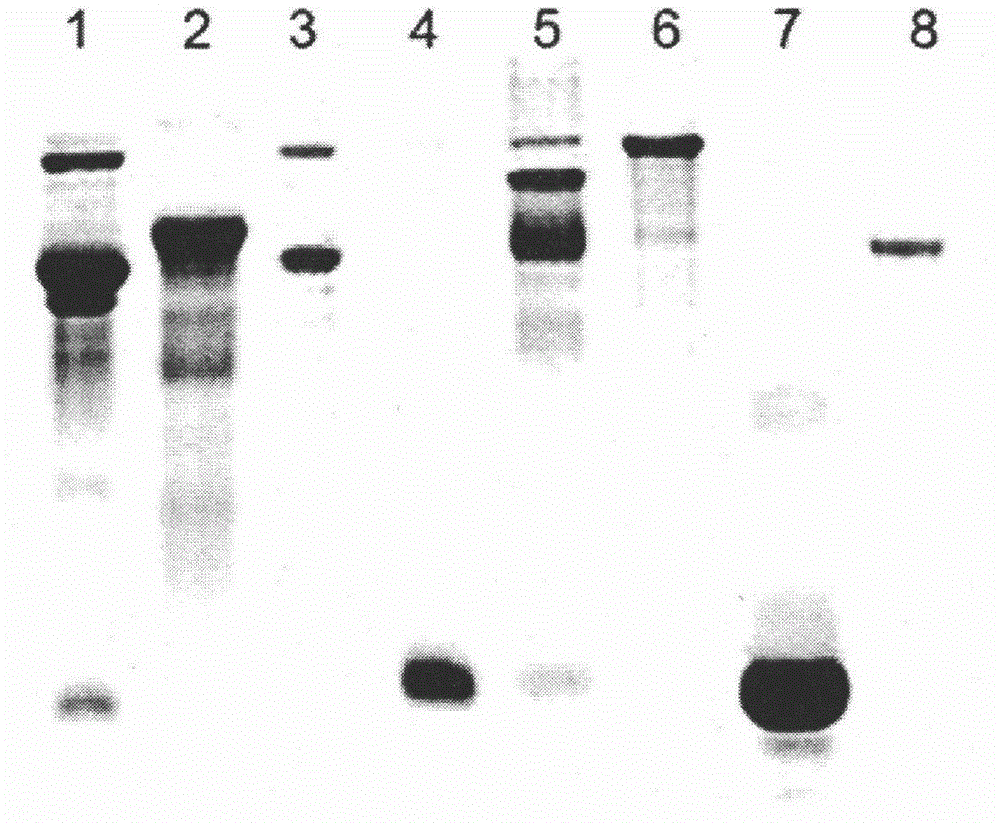

Image

Examples

Embodiment 1

[0031] (1) Preparation of high-efficiency hydrophobic interaction chromatography packings regulated by electrostatic groups

[0032]Use high-purity spherical silica gel as a blank matrix, firstly carry out acid treatment, reflux the silica gel with 1:1 hydrochloric acid at 120 degrees for 3-4 hours, cool, then wash repeatedly with distilled water until the solution is neutral, and dry it in vacuum overnight to make the silica gel surface The silanol is maintained at an appropriate level. Then activate the acid-treated silica gel with γ-glycidoxypropyltrimethoxysilane (TM-560), that is, slowly add an appropriate amount of TM-560 dropwise in a 50mmol / L sodium acetate solution at 90°C, React with silica gel for 4h, then wash with water, methanol and water successively, and dry in vacuum. The reaction between tryptophan and epoxidized silica gel is carried out in a dimethyl sulfoxide solution dried with sodium wire. After adding the reactant, it is ultrasonicated for 10 minutes, ...

Embodiment 2

[0036] (1) Preparation of high-efficiency hydrophobic interaction chromatography packings regulated by electrostatic groups

[0037] Use high-purity spherical silica gel as a blank matrix, firstly carry out acid treatment, reflux the silica gel with 1:1 hydrochloric acid at 120°C for 3-4 hours, cool, then wash repeatedly with distilled water until the solution is neutral, and dry it in vacuum overnight to make the silica gel surface The silanol is maintained at an appropriate level. Then activate the acid-treated silica gel with γ-glycidoxypropyltrimethoxysilane (TM-560), that is, slowly add an appropriate amount of TM-560 dropwise in a 50mmol / L sodium acetate solution at 90°C, React with silica gel for 4h, then wash with water, methanol and water successively, and dry in vacuum. The reaction between tryptophan and epoxidized silica gel is carried out in a dimethyl sulfoxide solution dried with sodium wire. After adding the reactant, it is ultrasonicated for 10 minutes, react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com