Device and method for mixing oxygen and sweetened tail gas

A technology for sweetening and tail gas, which is applied in the direction of mixing method, mixer, fluid mixer, etc., can solve the problems of oxidation reaction, no danger of sweetening tail gas explosion, explosion, etc., so as to prevent the passage of flame and prevent combustion The effect of explosive risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

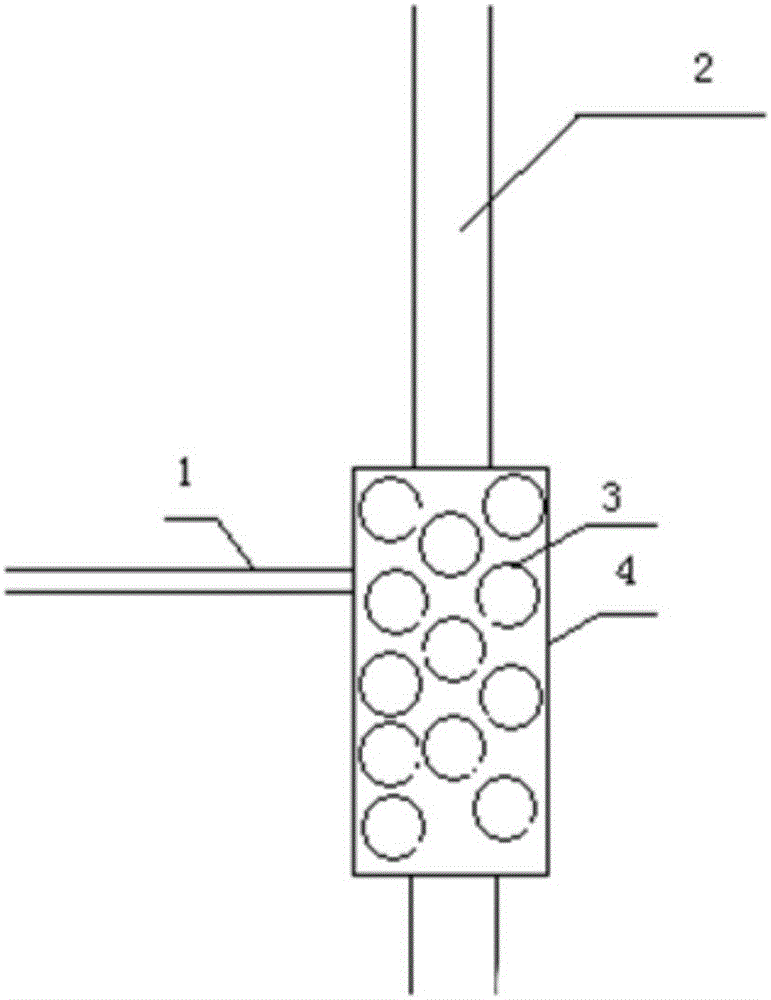

[0019] Such as figure 1 As shown, a device for mixing oxygen and sweetening tail gas includes a sweetening tail gas pipeline 2 and an oxygen pipeline 1, and the sweetening tail gas pipeline 2 communicates with the oxygen pipeline 1 and forms a section of oxygen mixing pipeline after communication. An oxygen mixer 4 is arranged on the oxygen mixing pipeline, and the oxygen pipeline 1 communicates with the oxygen mixer 4 , and the oxygen mixer 4 is filled with a plurality of barrier and explosion suppression balls 3 .

[0020] The invention also discloses a method for mixing oxygen and desulfurized tail gas, the method comprising the following steps:

[0021] Step 1: Determination of the intrinsic parameters of the site,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com