Improved horizontal screw centrifuge for corn protein dehydration and corn protein production technology

A decanter centrifuge and zein technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of large fluctuations in protein moisture, low yield, poor quality of protein powder, etc., and achieve changes in production process, increase yield and yield, and ensure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

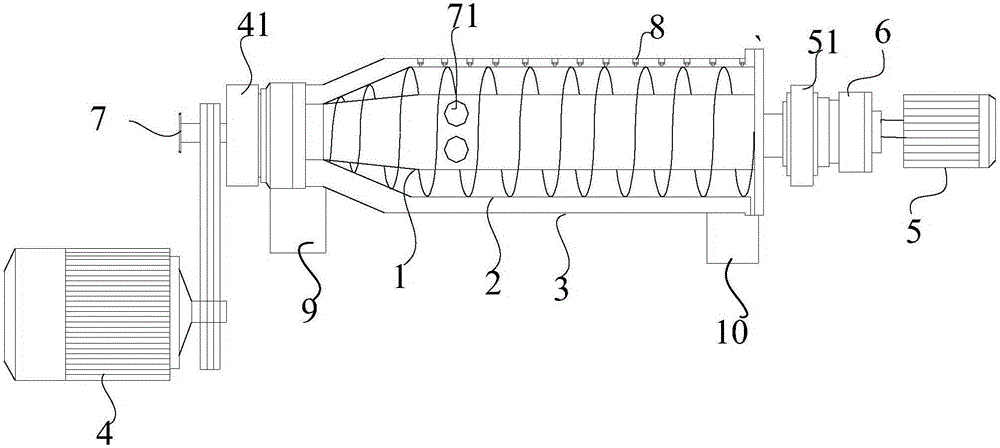

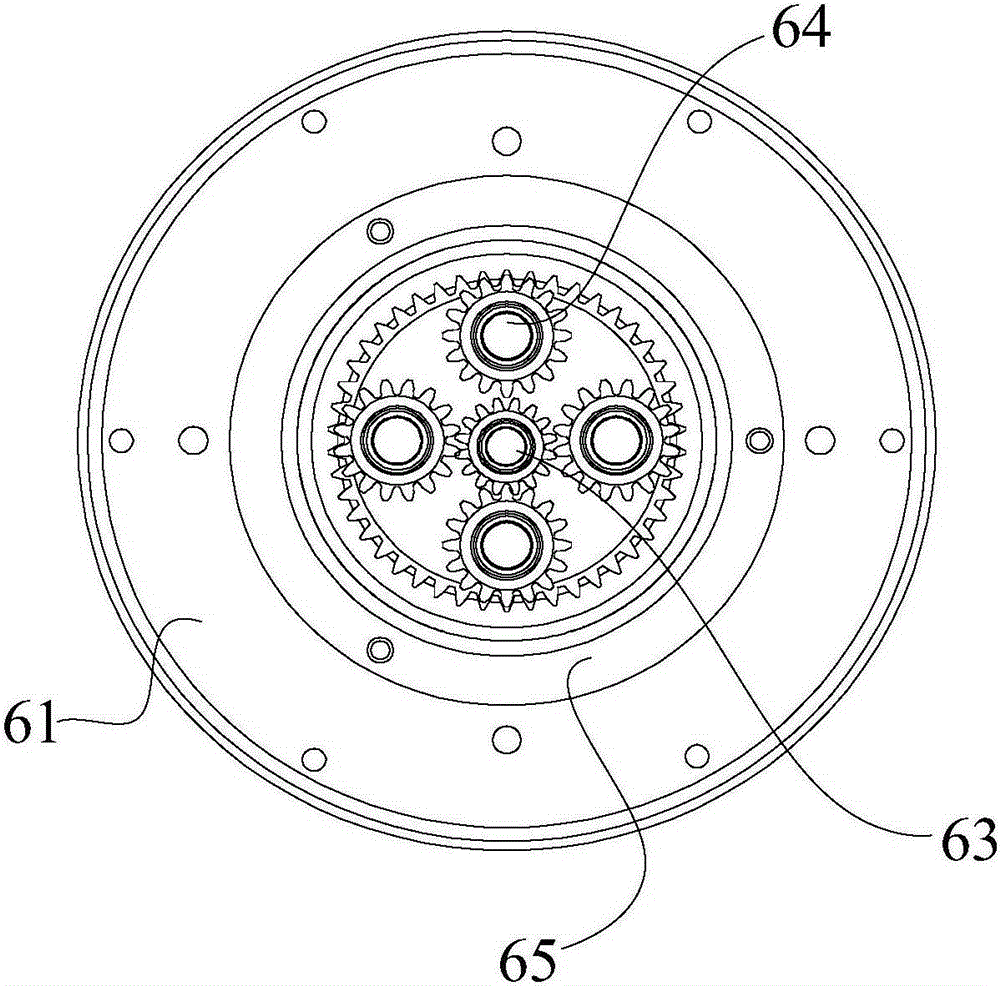

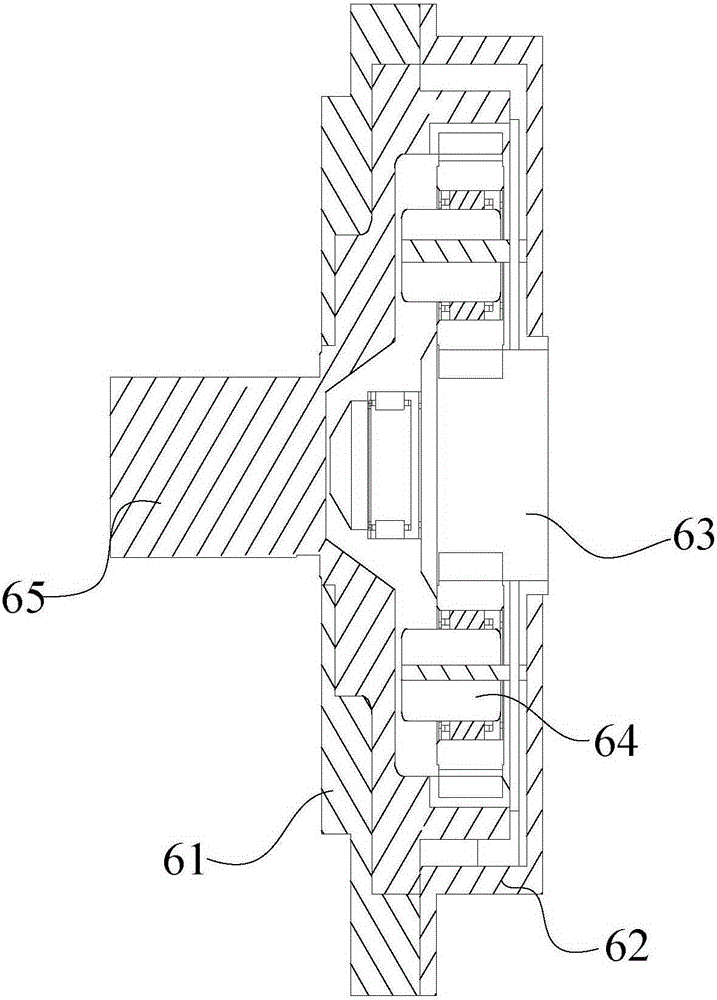

[0036] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present embodiment provides an improved decanter centrifuge for zein dehydration, which mainly includes a screw conveyor 1, a drum 2, a casing 3, and a screw conveyor connected to the drum 2. The main motor 4 and the auxiliary motor 5 connected with the screw conveyor 1, one end of the drum 2 is fixed on the drum bearing seat 41, and the end of the drum 2 is connected with the main motor 4 through an angle belt. The screw conveyor 1 and the drum 2 are fixed on the drum bearing seat 41 and the opposite end is fixed on the screw conveyor bearing seat 51. The screw conveyor 1 is set in the drum 2, and the drum 2 is set in the casing 3. The screw conveyor 1 includes a hollow conical part and a hollow cylindrical part at the front end. The three shapes of the drum 2, the screw conveyor 1 and the casing 3 are the same, and the tapered part of the screw conveyor 1 is far away from the cylindrical p...

Embodiment 2

[0051] Embodiment 2: This embodiment provides a kind of production technology of zein

[0052] The present invention is a continuous starch production process by-product protein dehydration process, the process mainly includes the following steps: a, purification; b, soaking; c, crushing; d, curved sieve; e, separation; f, concentration; g, dehydration; h, drying; i, packaging (in the follow-up description of this embodiment, many devices will be mentioned, these devices are common equipment in this field, so in this embodiment, its structure and function are not described in detail), specifically Say:

[0053] a. Purification step: the raw corn is sent to the scraper machine after passing the inspection, and sent to the corn drum sieve by the elevator, and some impurities are screened out, and sent to the corn storage bin by the elevator through the conveyor belt for corn soaking.

[0054] b. Soaking step: open the discharge valve of the corn silo, start the corn conveyor be...

Embodiment 3

[0062] Embodiment 3: This embodiment provides another kind of zein production process:

[0063]The basic difference between this embodiment and Embodiment 2 lies in the dehydration step, and the dehydration step is as follows: After the drum and the screw conveyor of the improved decanter centrifuge are used for dehydration of zein to full speed, the protein milk is fed into The material inlet enters the screw conveyor, and the flow rate of the feed is 30t / h. The protein milk enters the drum through the feed outlet in the screw conveyor. At this time, the rotation speed of the drum is 3100r / min. Under the action of the drum, a constant speed difference of 30r / min is generated, so that centrifugal force is formed in the drum, and the protein with a larger specific gravity is deposited on the inner wall of the drum to form a ring-shaped protein layer, which is finally conveyed by the screw conveyor. The spiral blades on the top push the dehydrated protein out of the discharge po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com