Preparation method of soybean milk with high content of nutritional ingredients

A technology for nutrients and soy milk, applied in dairy products, milk replacers, applications, etc., can solve the problems of insufficient extraction of beneficial substances in the human body, and achieve the effects of good application effect, increased penetration ability, and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

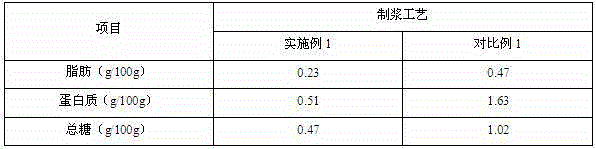

Embodiment 1

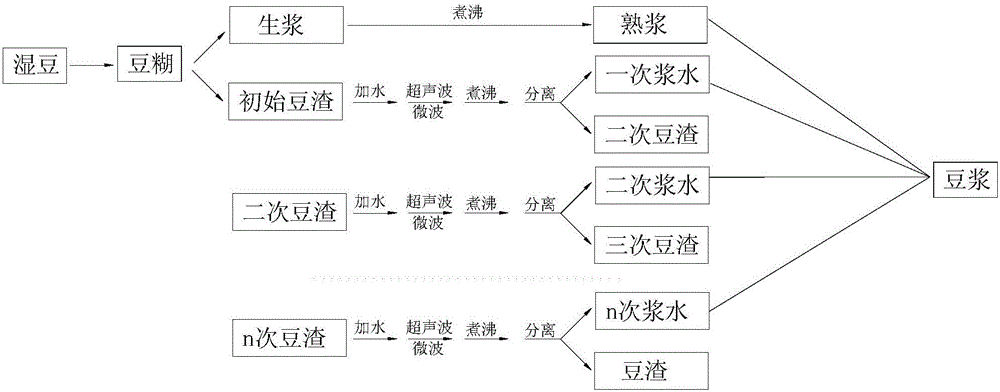

[0029] Such as figure 1 Shown, a kind of preparation method of the soya-bean milk with high nutritive ingredient content comprises steps:

[0030] 1) Soak dry beans in water, and stop soaking when the water content of wet beans meets the weight ratio of wet beans to dry beans before soaking is 2:1; add water to wet beans (the amount of water added to wet beans meets the ratio of wet beans to water The weight ratio of the bean paste is 1:7), using a grinding wheel mill to grind the wet soybeans into bean paste, and the diameter of the bean paste in the bean paste is 120 μm; separate the bean paste to obtain raw pulp and initial bean dregs;

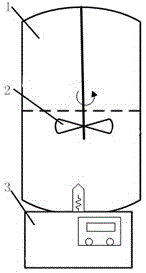

[0031] 2) Put the initial bean dregs in a closed cooking tank 1 with ultrasonic and microwave equipment 3 on the side or bottom (such as figure 2 shown) and add water (mass ratio of initial bean dregs to added water is 1:6), turn on the ultrasonic and microwave equipment, and perform ultrasonic and microwave treatment on the initial bean ...

Embodiment 2

[0037] Such as figure 1 Shown, a kind of preparation method of the soya-bean milk with high nutritive ingredient content comprises steps:

[0038] 1) Soak dry beans in water, stop soaking when the water content of wet beans meets the weight ratio of wet beans to dry beans before soaking is 2.5:1; add water to wet beans (add water to wet beans to meet the wet beans and water The weight ratio of the bean paste is 1:4), using a grinding wheel mill, a colloid mill or a fresh mill to grind the wet soybeans into a bean paste, and the diameter of the bean paste in the bean paste is 60 μm; separate the bean paste to obtain raw pulp and initial bean paste;

[0039]2) Put the initial bean dregs in the closed pulp cooking tank 1 with ultrasonic and microwave equipment 3 on the bottom (such as figure 2 shown) and add water (mass ratio of initial bean dregs to added water is 1:4), turn on the ultrasonic and microwave equipment, and perform ultrasonic and microwave treatment on the initia...

Embodiment 3

[0045] Such as figure 1 Shown, a kind of preparation method of the soya-bean milk with high nutritive ingredient content comprises steps:

[0046] 1) Soak dry beans in water, stop soaking when the water content of wet beans meets the weight ratio of wet beans to dry beans before soaking is 2.3:1; add water to wet beans (add water to wet beans to meet the wet beans and water The weight ratio of the bean paste is 1:10), and the wet soybeans are ground into bean paste by freshly milling, and the diameter of the bean dregs in the bean paste is 180 μm; the raw bean paste and the initial bean dregs are obtained by separating the bean paste;

[0047] 2) Put the initial bean dregs in the closed pulp cooking tank 1 with ultrasonic and microwave equipment 3 on the bottom (such as figure 2 shown) and add water (mass ratio of initial bean dregs to added water is 1:8), turn on the ultrasonic equipment, and perform ultrasonic treatment on the initial bean dregs; The tank is provided with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com