Continuous plating device

A plating and plating solution technology, applied in gymnastics equipment, sports accessories, muscle training equipment, etc., can solve problems such as scratches, long plating time, and decreased plating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention will be described in more detail with reference to the accompanying drawings.

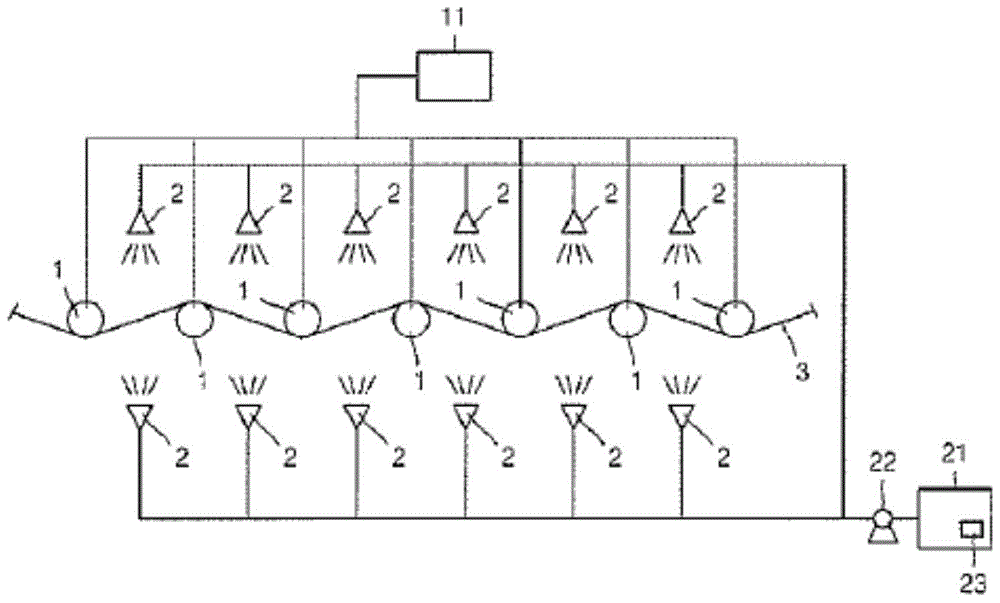

[0038] figure 1 This is a plan view schematically showing a continuous plating apparatus according to an embodiment of the present invention.

[0039] refer to figure 1 , the continuous plating device includes a cathode roll 1 and a spray unit 2 .

[0040] like figure 1 As shown, a plurality of the cathode rolls 1 and the spray unit 2 may be provided, but it is not necessarily limited to these, and at least one or more may be provided.

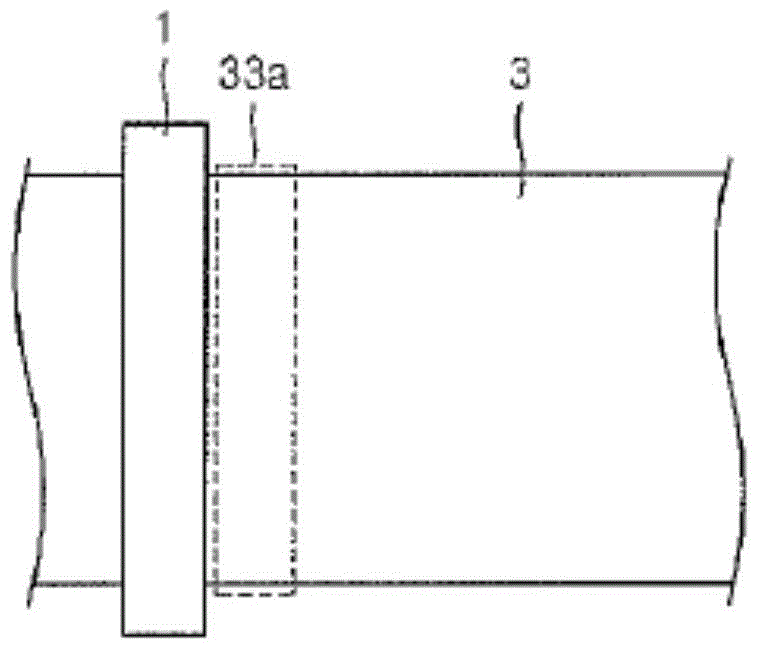

[0041] The material to be plated 3 including the pattern to be plated is arranged so as to pass between the plurality of cathode rolls 1 .

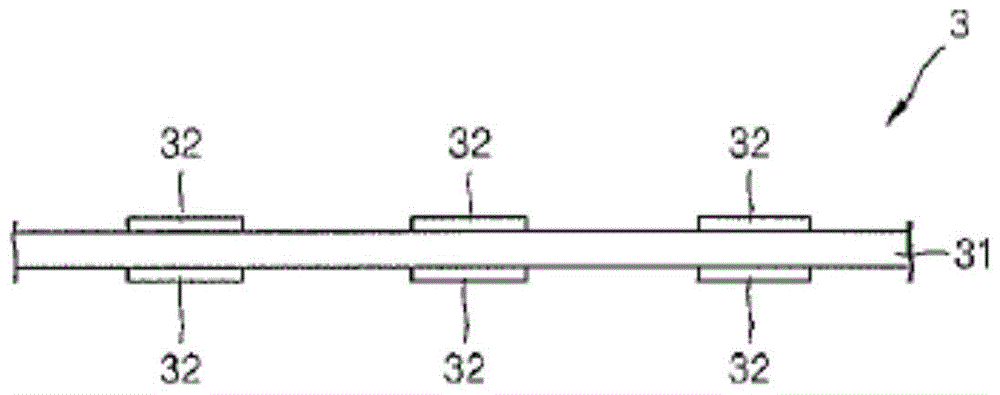

[0042] like figure 2 As shown, the material to be plated 3 may include a base member 31 in the form of a film, and a plurality of pads 32 formed on the surface of the base member. A plated layer may be formed on the contact point between the pad 32 and the cathode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com