Lithium iron phosphate anode material and lithium iron phosphate secondary battery

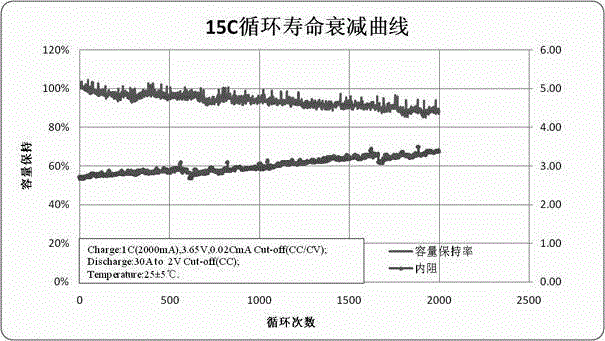

A technology of lithium iron phosphate and positive electrode materials, which is applied in the field of lithium-ion batteries, can solve the problems of reducing the mechanical strength of aluminum foil, increasing the surface area, and limited effect, and achieve the effect of improving power and cycle life, with small growth rate and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A lithium iron phosphate positive electrode material, the lithium iron phosphate positive electrode material includes the following raw materials in parts by weight:

[0042] 70 parts of lithium iron phosphate

[0043] Dispersed conductive agent 5 parts

[0044] Concentrated conductive agent 7.5 parts

[0045] 12 parts of synergistic conductive agent

[0046] 5 parts of binder.

[0047] 0.5 parts of other additives

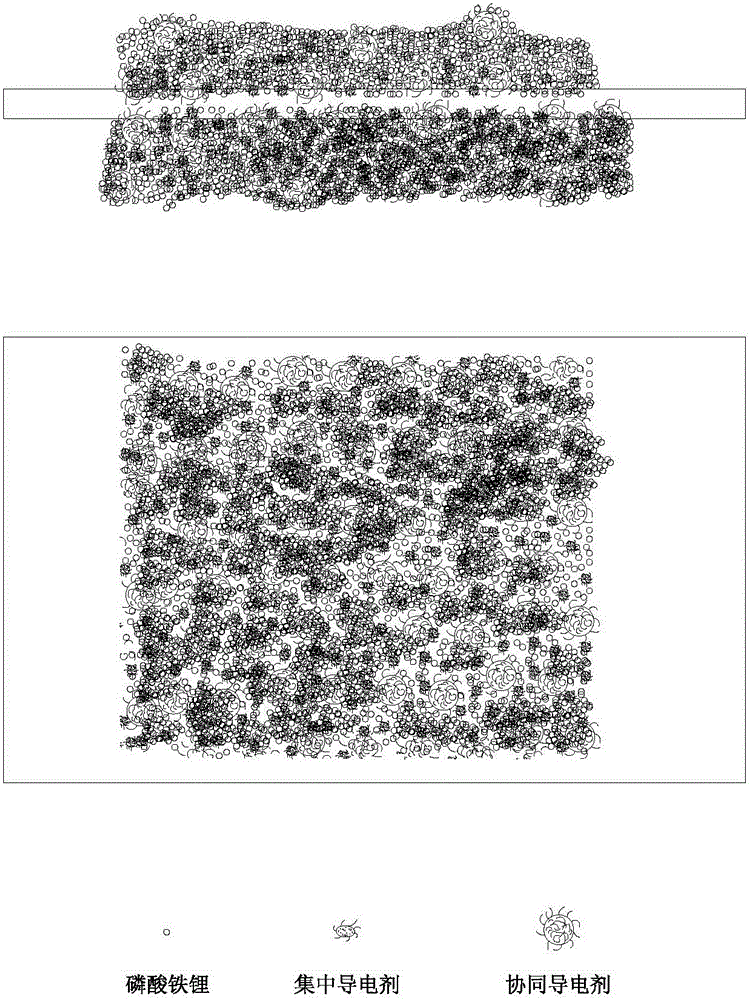

[0048] The dispersed conductive agent is SuperC65 carbon black conductive agent.

[0049] The concentrated conductive agent is KS-6 conductive graphite, and the particle size D50 of the concentrated conductive agent is 3.5 μm.

[0050] The synergistic conductive agent is lithium cobaltate, and the particle size D50 of the synergistic conductive agent is 5.8 μm.

[0051] The adhesive is Solef-5130PVDF oily adhesive.

[0052] The other auxiliary agent is dispersant KD-1.

[0053] A lithium iron phosphate secondary battery, the positive electrode of th...

Embodiment 2

[0055] A lithium iron phosphate positive electrode material, the lithium iron phosphate positive electrode material includes the following raw materials in parts by weight:

[0056] 75 parts of lithium iron phosphate

[0057] Dispersed conductive agent 5 parts

[0058] Concentrated conductive agent 1 part

[0059] 13.5 parts of synergistic conductive agent

[0060] 5 parts binder

[0061] 0.5 parts of other additives.

[0062] The dispersed conductive agent is a SuperC45 carbon black conductive agent, and the particle size D50 of the dispersed conductive agent is 0.1 μm.

[0063] The concentrated conductive agent is KS-6L conductive graphite, and the particle size D50 of the concentrated conductive agent is 3.5 μm.

[0064] The synergistic conductive agent is lithium manganate or lithium nickelate, and the particle size D50 of the synergistic conductive agent is 10 μm.

[0065]The adhesive is PVDF oily adhesive, and the PVDF oily adhesive is Solef-6020PVDF oily adhesive,...

Embodiment 3

[0069] A lithium iron phosphate positive electrode material, the lithium iron phosphate positive electrode material includes the following raw materials in parts by weight:

[0070] Lithium iron phosphate 80 parts

[0071] 6 parts of dispersed conductive agent

[0072] Concentrated conductive agent 2 parts

[0073] 7.5 parts of synergistic conductive agent

[0074] 3.5 parts of binder

[0075] 1 part of other additives.

[0076] The dispersed conductive agent is SuperPLi carbon black conductive agent.

[0077] The concentrated conductive agent is GF-8 conductive graphite, and the particle size D50 of the concentrated conductive agent is 4 μm.

[0078] The synergistic conductive agent is lithium nickel cobalt manganese oxide, lithium nickel manganese oxide or LiNi 0.5 mn 1.5 o 4 , the particle size D50 of the synergistic conductive agent is 12 μm.

[0079] The adhesive is LA-132 water-based adhesive.

[0080] The other auxiliary agent is dispersant KD-1.

[0081] A l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com