Substrate-free LED filament and manufacturing method thereof, and substrate-free LED filament lamp

A technology of LED filament and manufacturing method, which is applied in the field of substrate-less LED filament lamps, can solve the problems of high cost and complex manufacturing process of LED filament, and achieve the effects of low cost, simple manufacturing process and small thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

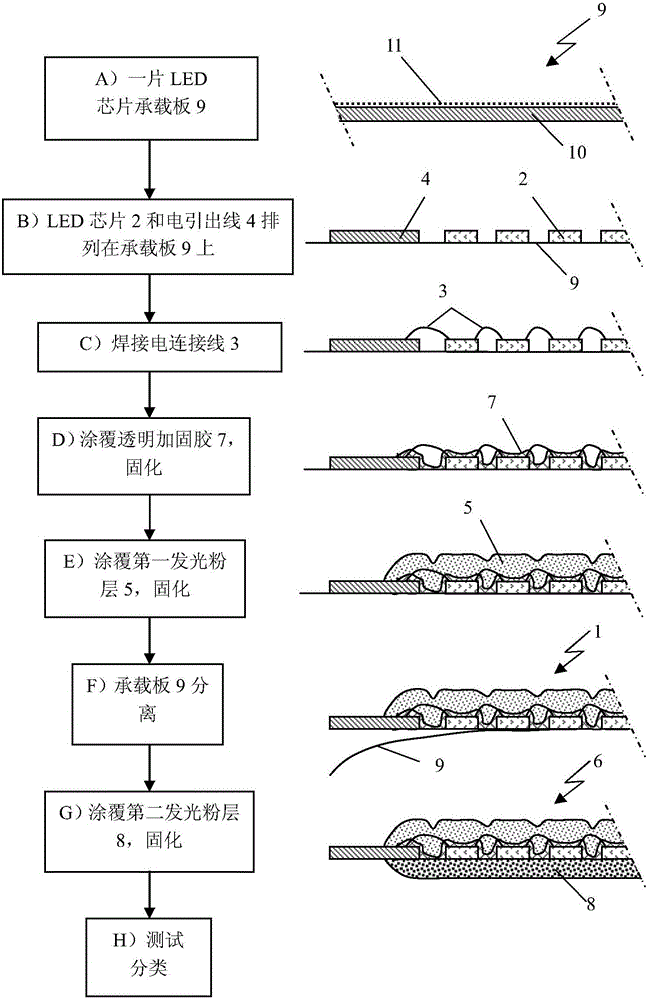

[0064] The present invention will be further described below in conjunction with the drawings and embodiments.

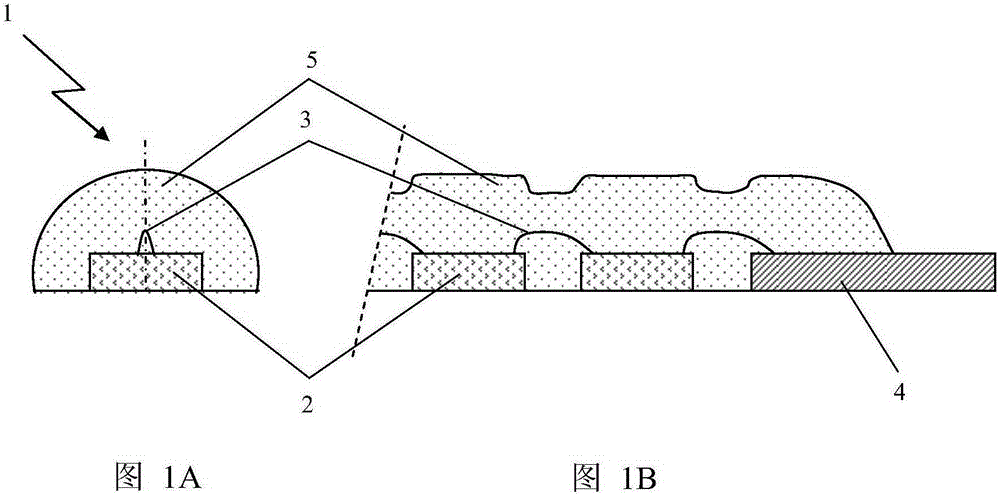

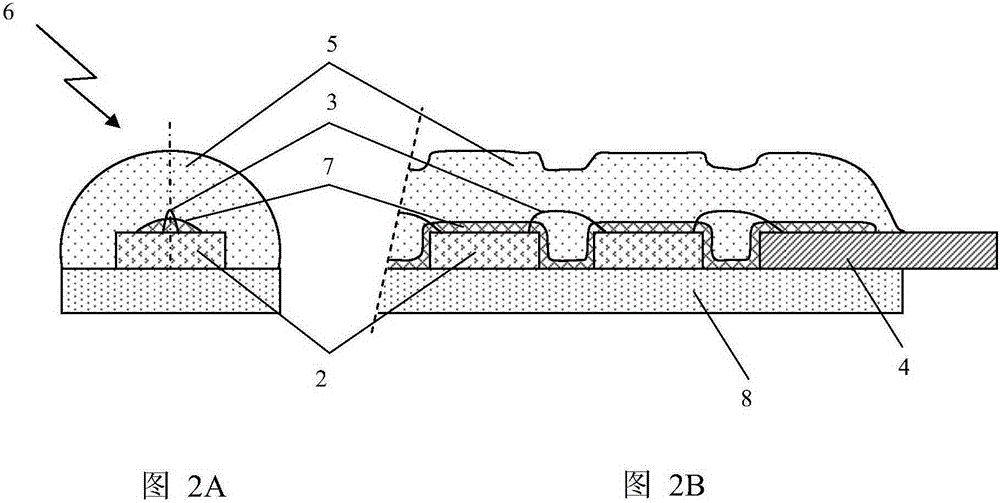

[0065] Figure 1A with Figure 1B It is a kind of substrate-less LED filament of the present invention---a schematic cross-sectional structure diagram of an embodiment of the initial substrate-less LED filament 1, wherein Figure 1A Is a schematic diagram of the radial section of the filament, Figure 1B A schematic diagram of a partial axial section of one end of the filament. In the figure, 2 is the LED chip, 3 is the electrical connection line between the chip 2 and between the chip and the electrical lead 4; 5 is the first luminescent powder on the welding end of the electrical connection line of the LED chip 2 and the electrical lead 4 Floor.

[0066] The initial substrate-less LED filament 1 can be used to manufacture LED filament lamps; if the LED chip used is a transparent chip that emits blue light, blue light will be emitted directly; if the LED chip used is an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com