Device and test method of alloy solidification synchronous radiation imaging static magnetic field composite direct current effect

A direct current and static magnetic field technology, applied in the direction of using radiation for material analysis, etc., can solve problems such as device blanks, and achieve the effects of improving performance, increasing magnetic induction intensity, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

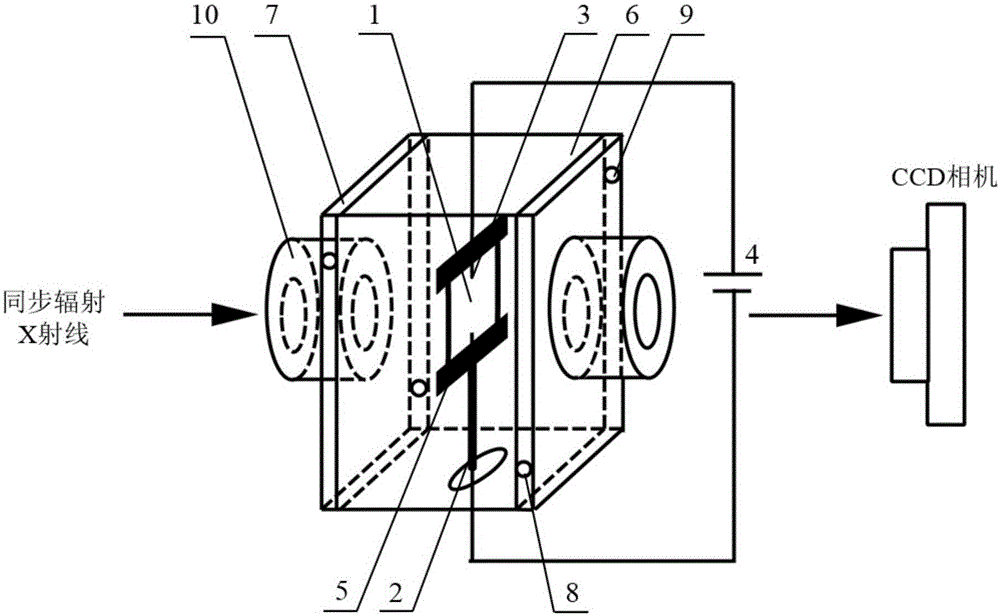

[0037] In order to meet the requirements of the experimental method and experimental device for using synchrotron radiation X-ray imaging technology to study the electromagnetically regulated alloy solidification process, this embodiment provides an alloy solidification synchrotron radiation imaging static magnetic field compound DC action device, such as figure 1 As shown, including power supply circuit and micro heating furnace;

[0038] The micro-heating furnace is a cavity with a set accommodation space. The cavity in this embodiment is a rectangular box, and its specific size is controlled below 200cm×100cm×30cm, so as to adapt to synchrotron radiation X-rays and CCD detectors. The spacing of the micro-heating furnace cavity is provided with a heating unit 5, the heating unit 5 of the micro-heating furnace is a Peltier element or a resistance heating element, and its maximum heating temperature is as high as 500 ° C; in the micro-heating furnace cavity A heat insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com