A Beam Type Conversion Device for Drop Weight Impact Tensile Test that Can Eliminate the Influence of Inertial Force

A drop-weight impact and tensile test technology, which is applied in the direction of testing material strength with one-time impact force, measuring device, and testing material strength with stable tension/pressure, can solve the problem of quantitative inertial force and complex structure of specimen size nodes , small lateral stiffness and other issues, to achieve the effect of not being prone to overall instability, simple structure, simple processing and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

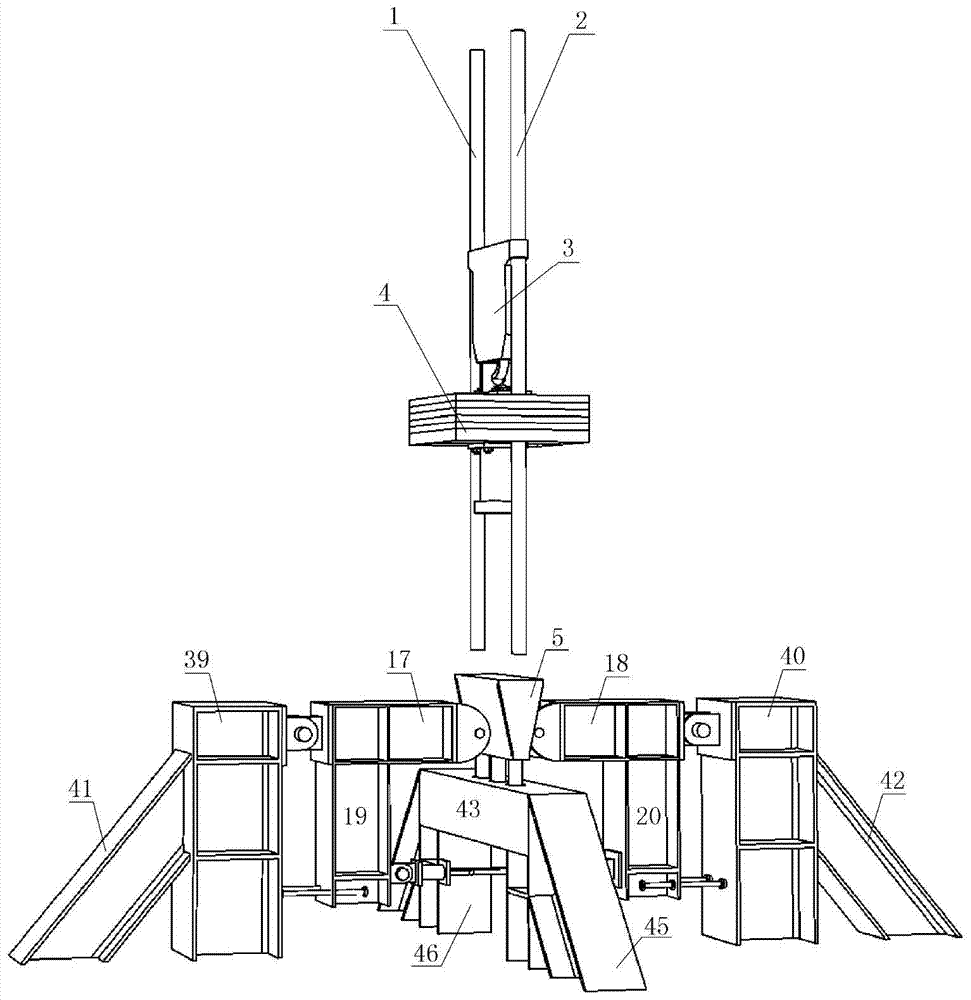

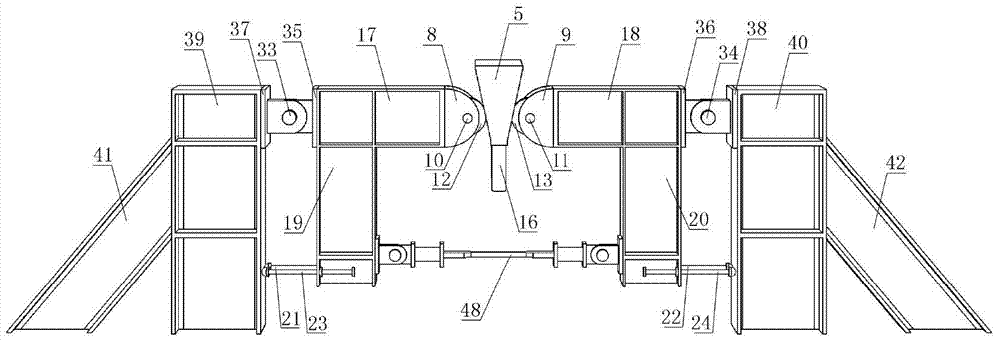

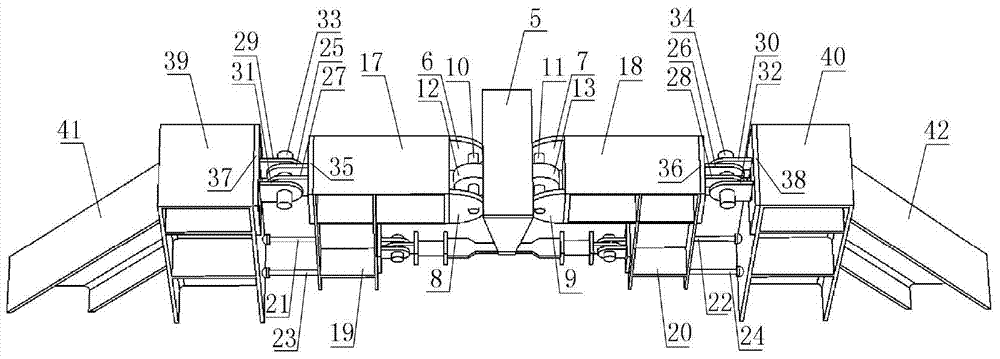

[0034] A drop-weight impact tensile test beam-type conversion device that can eliminate the influence of inertial force is composed of a drop-weight testing machine, a beam-type force transmission direction conversion mechanism, a limit frame and a specimen connector, see figure 1 . drop weight testing machine figure 1 As shown, it consists of guide rails 1, 2, positioning fixture 3, and hammer body 4. The positioning fixture 3 is fixed on the guide rails 1 and 2, and the hammer body 4 is hooked on the positioning fixture 3. Beam force transmission direction conversion mechanism such as figure 2 and image 3 As shown, it consists of wedge-shaped steel block 5, twelve ear plates 6, 7, 8, 9, 25, 26, 27, 28, 29, 30, 31, 32, four node pins 10, 11, 33, 34. Two roller bearings 12, 13, three wedge shafts 14, 15, 16, two horizontal force transmission beams 17, 18, two vertical force transmission beams 19, 20, four positioning screws 21, 22, 23 , 24, four node end plates 35,36,37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com