Testing apparatus of dynamic response of filler wall under combustible gas explosion

A test device and gas explosion technology, which is applied in the field of dynamic response test devices, can solve the problems of incapable of filling wall loading test, inability to obtain filling wall anti-blast performance, failure form, etc., and achieve the effect of eliminating relative displacement and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

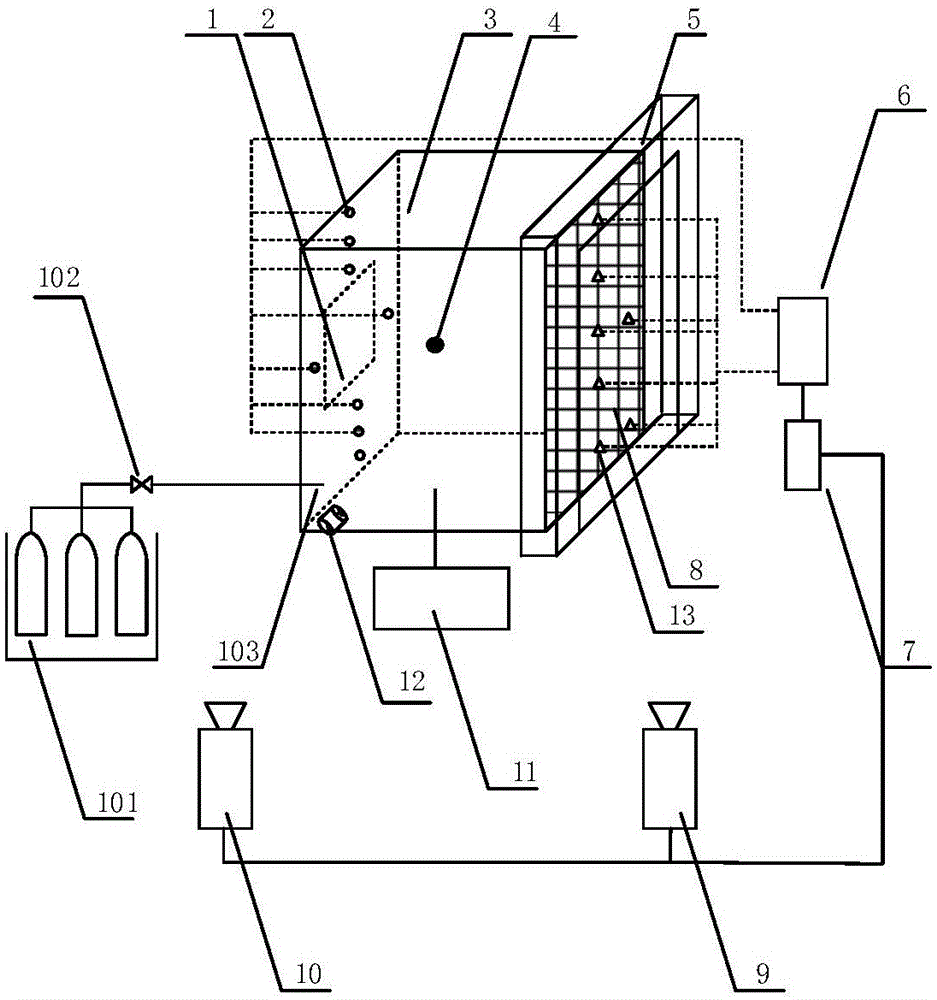

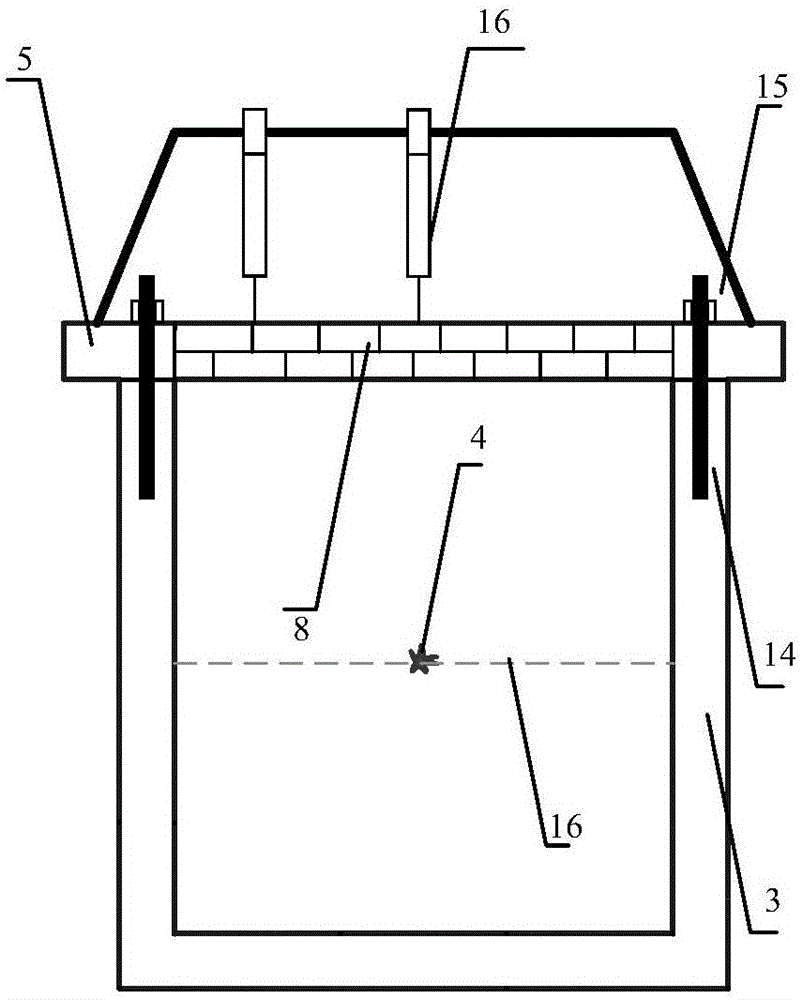

[0019] Such as figure 1 with 2 As shown, the dynamic response test device for combustible gas explosion of the filled wall of the present invention includes a reinforced concrete room 3 without a rear side wall, a reinforced concrete frame 5 fixedly connected to the rear side wall of the room 3, and the frame 5 is prefabricated with The test brick wall 8 is provided with a blast vent hole 1 on the front side wall of the room 3, and the blast vent material is installed in the blast vent hole 1, and a plurality of pressure sensors are arranged on the inside of the front side wall of the room 3 2. A displacement gauge 16 is arranged on the outside of the test brick wall 8, and the pressure sensor 2 and the displacement gauge 16 are connected to the data collector 6 for signals. An ignition head 4 is provided in the room 3. In the room 3 There is a combustible gas source connected to room 3 outside.

[0020] The data collector 6 can be connected with the computer 7 again. Ignit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com