A kind of mycelia drying method

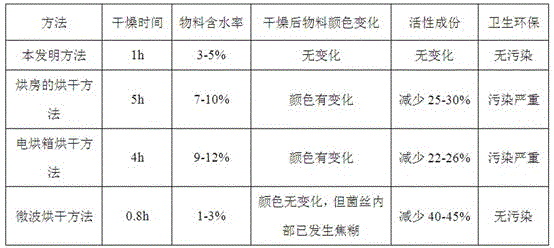

A drying method and technology for mycelium, which are applied to drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of long drying cycle, poor quality of mycelium, low efficiency, etc., and achieve short drying cycle and drying time. Short, dry and thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of mycelia drying method, comprises the following steps:

[0029] (1) Send the remaining initial hyphae with a water content of 75% after extracting the fermentation product into the cloth bin of the microwave hot air composite drying equipment for mechanical cloth distribution, and spread the initial mycelia on the conveyor belt; after cloth, the conveyor belt The thickness of the upper initial hyphae is 1cm, and the width is 180cm;

[0030] (2) Transfer the initial hyphae after the cloth to the drying chamber of the microwave hot air composite drying equipment, and use microwave and hot air to dry at the same time, and at the same time, use a dehumidifier to discharge the moisture in the drying chamber of the microwave hot air composite drying equipment ; When the moisture content of the initial hyphae is 20%, the material is discharged, and the discharge temperature is 80 ° C; wherein, the microwave power density of the microwave hot air composite drying equip...

Embodiment 2

[0035] A kind of mycelia drying method, comprises the following steps:

[0036] (1) Send the remaining initial hyphae with 80% water content after extracting the fermentation product into the distribution bin of the microwave hot air composite drying equipment, and carry out mechanical distribution, and spread the initial mycelium on the conveyor belt; the conveyor belt after the cloth The thickness of the upper initial hyphae is 1.5cm, and the width is 170cm;

[0037] (2) Transfer the initial hyphae after the cloth to the drying chamber of the microwave hot air composite drying equipment, and use microwave and hot air to dry at the same time, and at the same time, use a dehumidifier to discharge the moisture in the drying chamber of the microwave hot air drying equipment; When the moisture content of the initial mycelia is 22%, the material is discharged, and the temperature of the material is 85°C; wherein, the microwave power density of the microwave hot air composite dryin...

Embodiment 3

[0042] A kind of mycelia drying method, comprises the following steps:

[0043] (1) Send the remaining initial hyphae with a water content of 78% after extracting the fermentation product into the cloth bin of the microwave hot air composite drying equipment for mechanical cloth, and spread the initial mycelium on the conveyor belt; after cloth, the conveyor belt The thickness of the upper initial mycelium is 2cm, and the width is 170cm;

[0044] (2) Transfer the initial hyphae after the cloth to the drying chamber of the microwave hot air composite drying equipment, and use microwave and hot air to dry at the same time, and at the same time, use a dehumidifier to discharge the moisture in the drying chamber of the microwave hot air drying equipment; When the moisture content of the initial hyphae is 22%, the material is discharged, and the temperature of the material is 90°C; wherein, the microwave power density of the microwave hot air composite drying equipment is 15KW / m 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com