Novel device for closure of small pump station

A new device and pumping station technology, applied in the direction of valve device, function valve type, valve details, etc., can solve the problems of check valve spool movement, easy failure and poor effect, so as to achieve convenient and reliable connection, prevent escape, Sealed and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

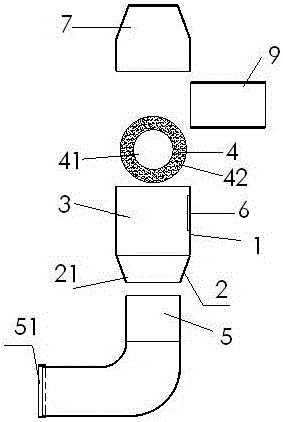

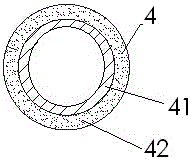

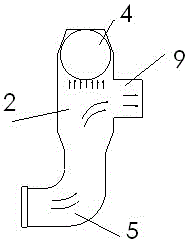

[0030] Embodiment 1: as figure 1 As shown, a new shut-off device for a small pumping station includes a valve body 1, a funnel-shaped valve seat 2 is provided at the lower part of the valve body 1, and the middle part of the valve body 1 is a cylindrical structure 3, and there is a cylindrical structure 3 inside the valve body 1. The spherical valve core 4, the valve seat 2 and the valve core 4 are sealable fits, the inlet connection end 5 is connected under the valve seat 2, the outlet connection end 6 is connected to the middle side of the valve body 1, and the upper part of the valve body 1 is connected to valve cover7.

[0031] The inlet connection end 5 is an elbow with a 90° bend, and its tail end is in a horizontal state. When the pump is started, for the valve seat 2 of the device, the water pressure at the water inlet is higher than the water pressure at the water outlet. The water pushes the spherical valve core 4 upwards from the bottom of the funnel-shaped valve s...

Embodiment 2

[0042] Embodiment 2: There are two outlet pipes, which are set according to the drainage requirements; when there is one outlet pipe, the outlet pipe and the water inlet pipe are arranged in parallel; when there are two outlet pipes, the outlet pipe and the water inlet pipe are arranged vertically. Such as Figure 7 shown.

Embodiment 3

[0043] Embodiment 3: The valve core is a spherical structure made of polypropylene, and there is a small metal ball for counterweight inside the spherical structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com