Method for multi-section blocking of covering rock damage band and synchronous leakage measuring

A damage zone and leakage detection technology, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., can solve the problems of heavy measurement workload, large blindness, and many times of movement, and achieve convenient maintenance and replacement with low workload. The effect of reducing and moving less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further clearly and completely described below in conjunction with specific embodiments.

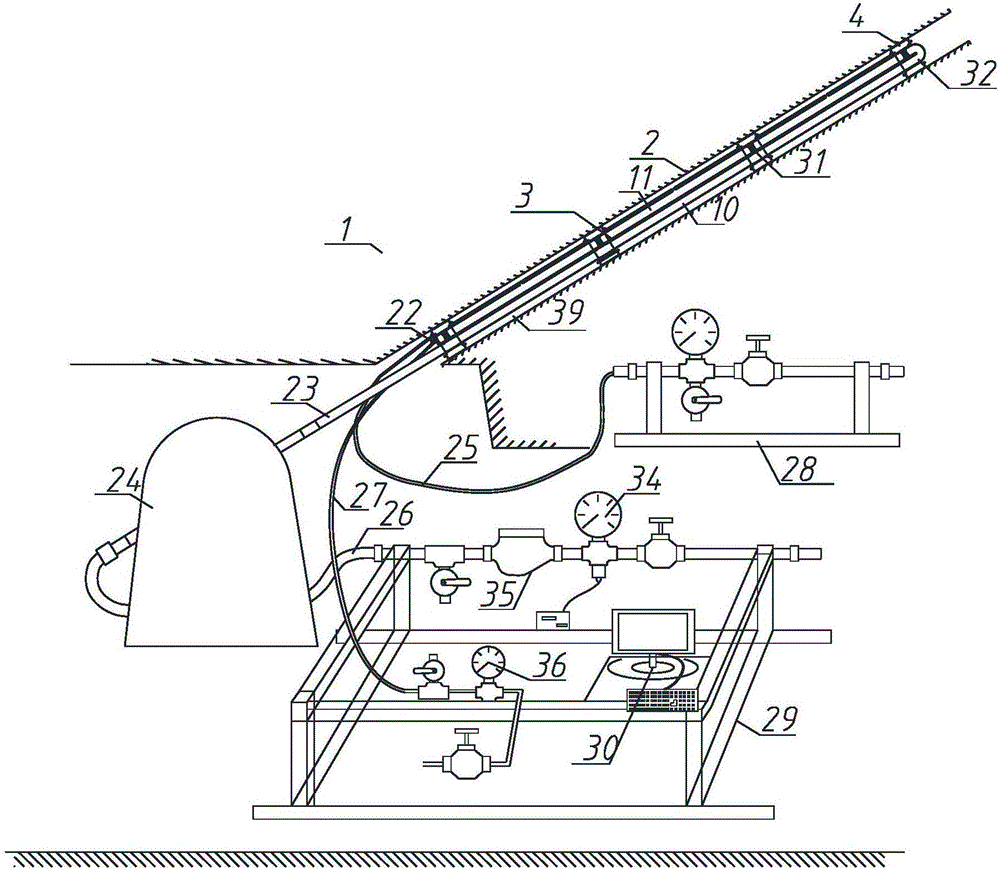

[0050] The multi-stage plugging and synchronous leakage detection method of the overlying rock failure zone of the present invention uses a system such as figure 1 As shown, it mainly includes detection system, blocking system and supply measurement system.

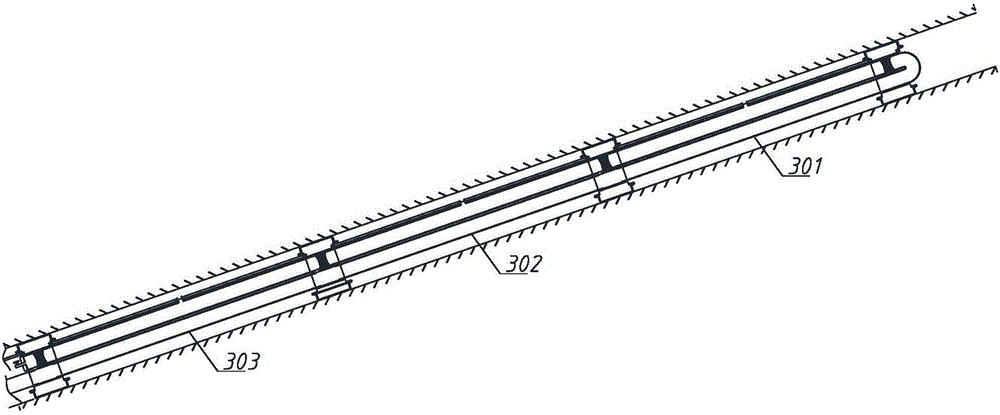

[0051] The probing system includes test probes 3, combined with figure 2 with image 3 As shown, the test probe is different from the prior art. It is not a whole, but is formed by connecting several detection units in sequence. It is the front detection unit 301, the middle one is the middle detection unit 302 and the tail detection unit 303 close to the outside, combined Figure 10-Figure 13 As shown, each detection unit includes a water inlet pipe 10, a return pipe 11, a pressure regulating valve 31, and an electronic flowmeter 20. The water inlet pipe and the return pipe are arranged in p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com