Connecting members of φ48 single steel pipe and combined steel formwork

A technology for connecting components and steel formwork, applied in the connection of formwork/formwork/work frame, on-site preparation of building components, building construction, etc. Project progress and other issues, to achieve the effect of reducing the amount of consumption, good integrity, and solving the problem of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

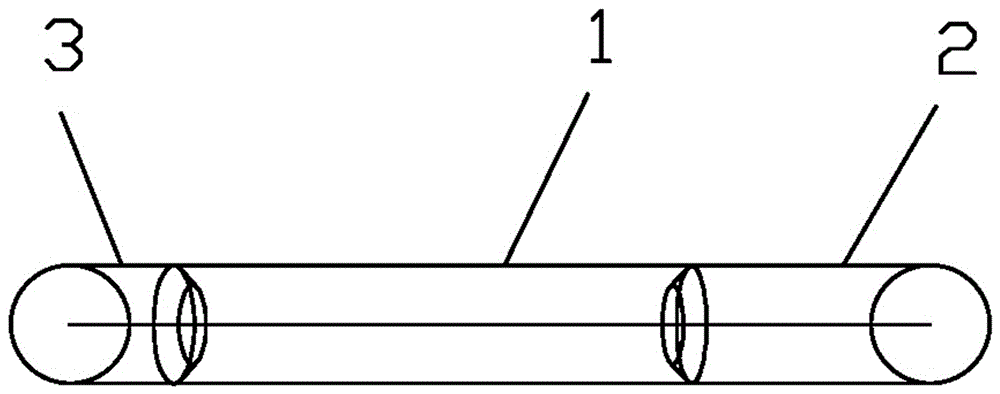

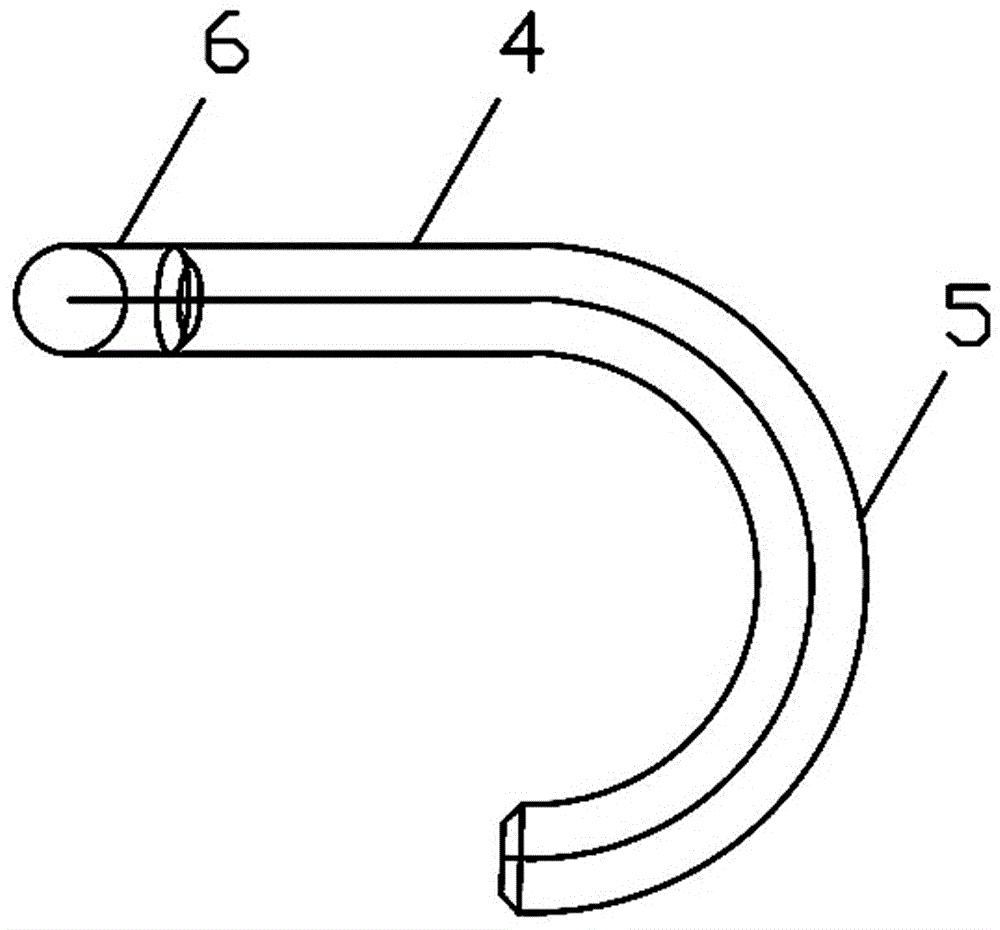

[0035] as attached figure 1 , 2 The shown ear clip 8 is in the shape of a human ear, and has a middle straight section 1 of the human ear clip and a large circular arc section 2 and a small circular arc section 3 extending from the middle straight section 1 of the human ear clip to both sides. , the middle straight section 1, large arc section 2, and small arc section 3 of the human ear card are in the same plane, the length of the middle straight section 1 of the human ear card 8 is 40.6mm, and the length of the large arc section 2 is 37mm , the length of the small arc section 3 is 21.3mm, the inner arc radius of the large arc section 2 of the human ear card 8 is 25mm, the outer arc radius is 37mm, the inner arc radius of the small arc section 3 is 10mm, and the outer arc radius The radius is 22mm, the angle between the vertical direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com