Counter-force device for super tonnage blasting platform

A counterforce device and ultra-large tonnage technology, which can be used in infrastructure testing, construction, infrastructure engineering, etc. It can solve the problems that the main girder cannot be transported to the construction site, the ballast platform is low in feasibility, and the safety risk is increased. , to achieve the effect of saving transportation, improving safety and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

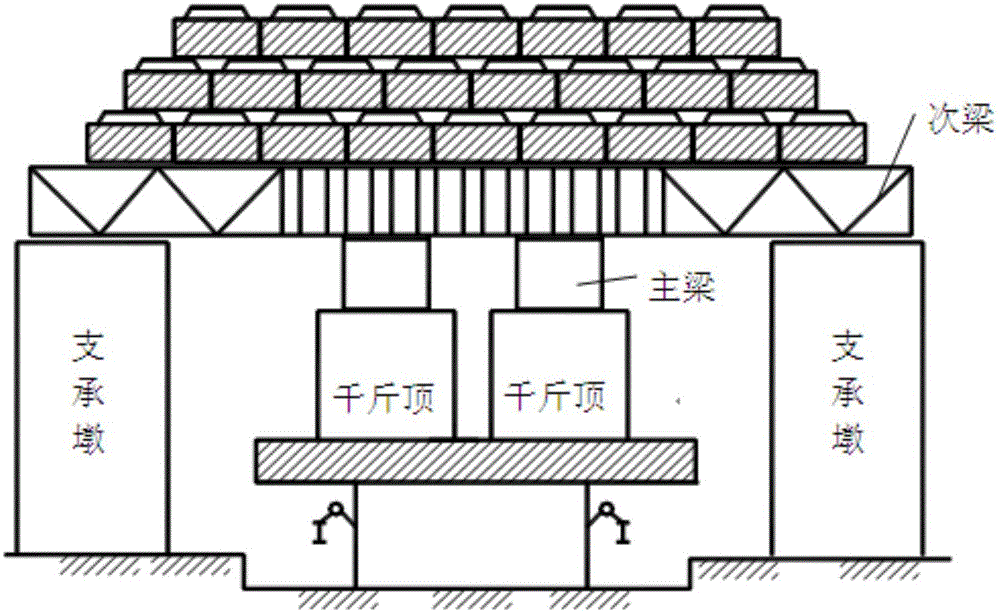

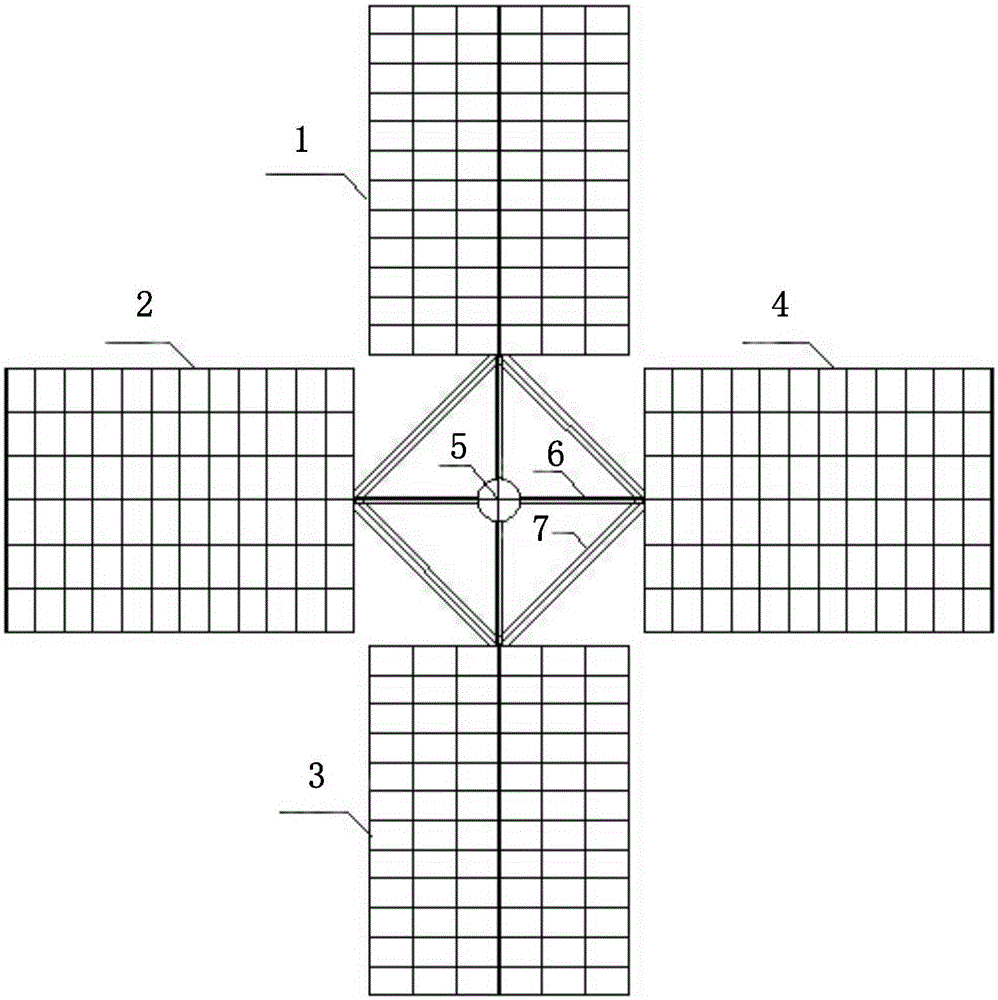

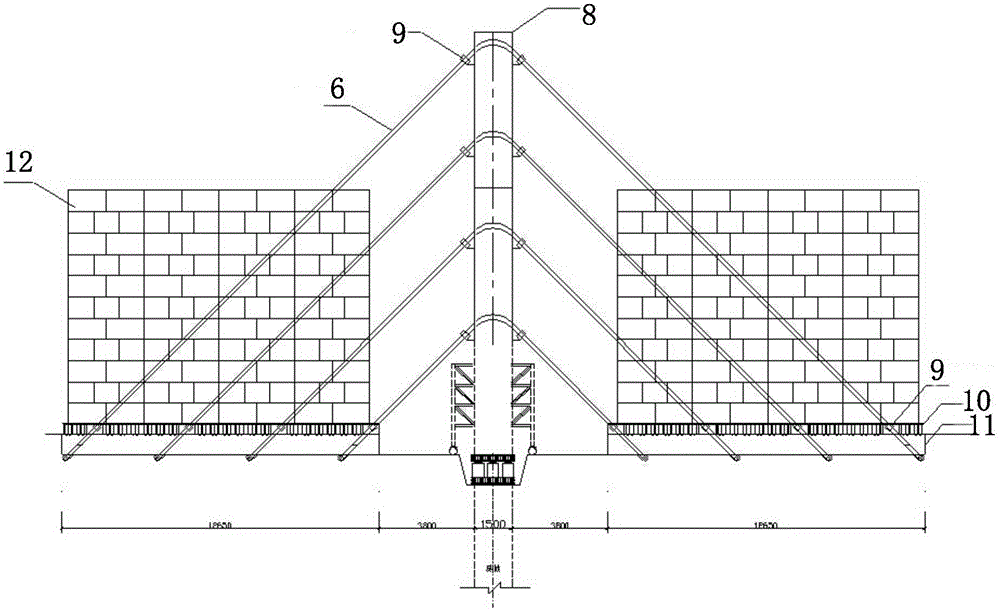

[0028] Figure 2-10 Shown is the counter force device of the super large tonnage ballast platform provided by the present invention, the counter force device includes a main tower 8, a stacked ballast platform, an anti-slip cross brace 7, several quick connectors 9, several counterweights 12 and Stay cables 6, the stacking and weighting platform is arranged around the main tower 8 at the center of the main tower 8, and the two ends of the anti-slip cross brace 7 respectively support the main beam of the stacking and weighing platform 11, the two ends of the stay cables 6 are respectively connected to the stacking weight platform and the main tower 8 through the quick connectors 9 in turn, and several counterweights 12 are evenly arranged on the Stacked on the weight platform. The tonnage can be increased by stacking and stacking, and the tonnage is highly expandable; the requirements for the bearing capacity of the foundation are low; the stability and safety of the platform ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com