Transverse galling machine and galling treatment method

A napping machine and horizontal technology, which is applied in the field of bridge deck construction, can solve the problems of not being able to complete the napping treatment at one time, consume manpower, and have little napping effect, so as to meet the needs of horizontal napping processing, easy to use and operate, and easy to use and operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

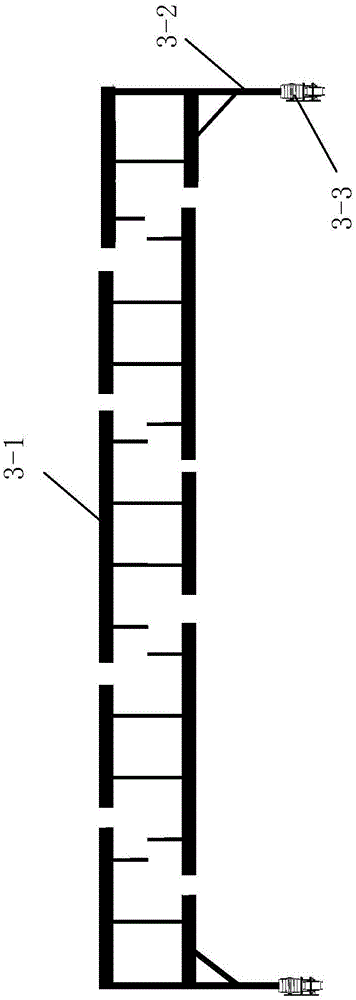

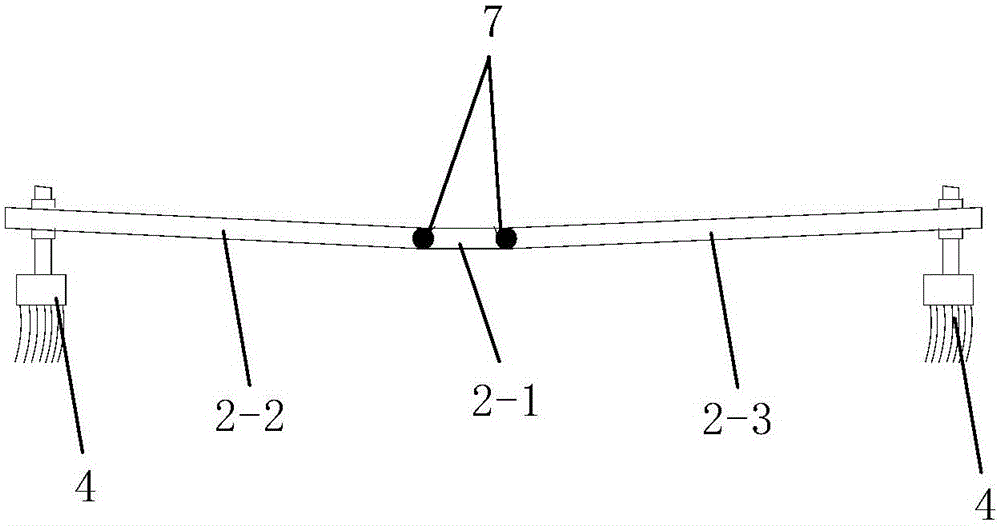

[0053] Such as figure 1 A kind of transverse napping machine shown, comprises the walking frame that moves from back to front along the longitudinal length direction of the area to be napped, the working frame 1 that is installed on the described walking frame, is arranged on the working frame 1 and can The traversing frame 2 that moves left and right on the working frame 1, the traversing drive mechanism that drives the traversing frame 2 to move left and right, and the traversing frame 2 drives the traversing frame 2 to move synchronously. A napping tool for performing transverse napping on the area to be napped, the traverse drive mechanism is connected to the traverse frame 2 through a transmission mechanism. The roughening tool is a scrub brush 4 and it is installed below the traversing frame 2 . The running frame includes a horizontal truss 3-1 located above the area to be roughened, two left and right vertical legs 3-2 respectively supported on the sides of the horizon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com