Cutting device used for towel belt

A material cutting device and towel technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of towel belts that cannot be fully automated, low processing efficiency, and different lengths of towel segments, and achieve fully automatic and fast The effect of material cutting and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

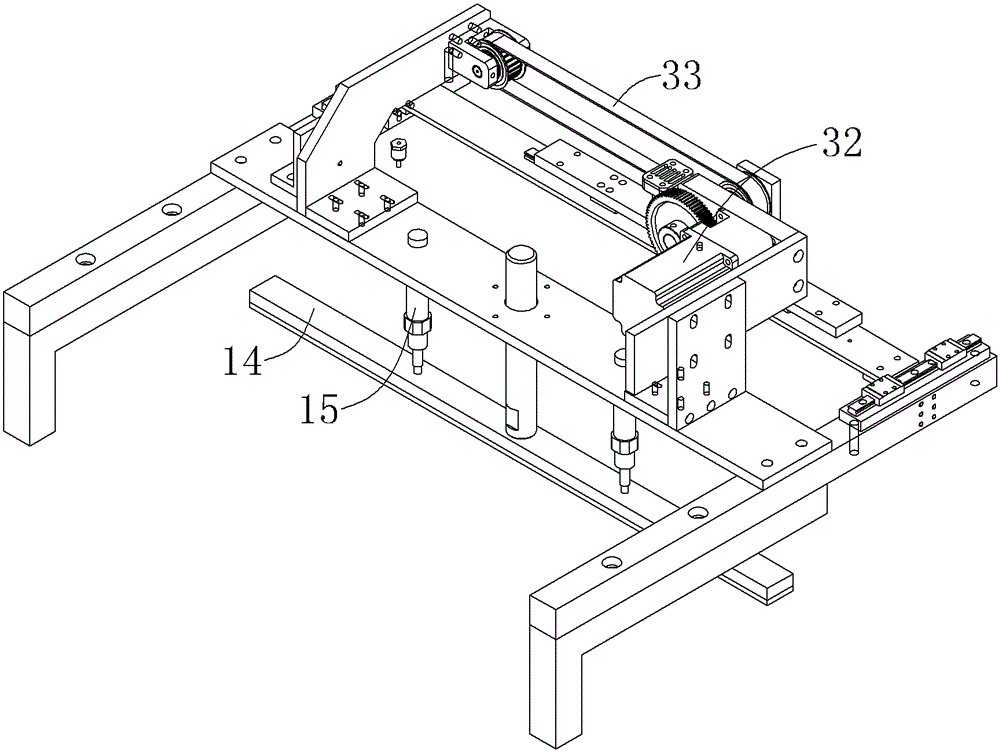

[0025] Figure 1 to Figure 8 Shown is the structural representation of the present invention.

[0026] The reference signs are: feeding frame 1, feeding roller group 11, mounting frame 12, platen 13, pressing plate 14, pressing cylinder 15, sliding mounting plate 2, pressing mounting plate 21, limit baffle 22 , Binder block 23, upper stop portion 23a, lower stop portion 23b, lift cylinder 24, lift guide rail 25, material guide rail 26, drive plate 3, drive bar 31, drive plate motor 32, drive plate timing belt 33, layering bar 4 , layer drive cylinder 41, cutter 5, cutter motor 51, cutter guide rail 52, cutter slide driver 53, cutter timing belt 54, shelf plate 6, first concave-convex teeth 6a, shelf cylinder 61, puller Mounting seat 7, material pulling motor 71, material pulling synchronous belt 72, material clamping bottom plate 73, material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com