Super-power moisture-absorbing towel and preparation method for same

A technology of hygroscopicity and towels, which is applied in the field of super hygroscopic towels and its preparation, can solve the problems of poor water absorption and poor applicability, and achieve the effects of super hygroscopicity, good air permeability, and improvement of body functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

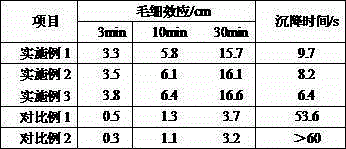

Embodiment 1

[0028] A kind of super hygroscopicity towel and preparation method thereof, the warp thread of bottom material is made of bamboo fiber 46.7%, combed cotton 41%, superfine fiber 12%, resin fiber 0.3% blending, weft thread is made of bamboo fiber 47.7%, combed cotton 41%, 11% superfine fiber, 0.3% resin fiber blend, and blend bamboo fiber and resin fiber, and at 600W, microwave radiation for 4 minutes, blend combed cotton with superfine fiber, and then blend with bamboo fiber resin Terry is the untwisted yarn that obtains by the raw material blending of following weight ratio: bamboo fiber 60%, superfine fiber 15%, combed cotton 10%, milk fiber 5%, modal fiber 5%, tea fiber 5%, obtain The yarn count of the twisted yarn is 38Tex, and the cut length of the fiber used is 43mm. The base material and the untwisted yarn are spun on the machine to obtain a super hygroscopic towel with loops on both sides of the base material.

Embodiment 2

[0030] A kind of super hygroscopicity towel and preparation method thereof, the warp thread of bottom material is made of bamboo fiber 46.6%, combed cotton 40%, superfine fiber 13%, resin fiber 0.4% blending, weft thread is made of bamboo fiber 46.7%, combed cotton 41%, 12% superfine fiber, 0.3% resin fiber blend, and blend bamboo fiber and resin fiber, and at 650W, microwave radiation for 5 minutes, blend combed cotton with superfine fiber, and then blend with bamboo fiber resin Terry is the untwisted yarn that obtains by the raw material blending of following weight ratio: bamboo fiber 60%, superfine fiber 15%, combed cotton 10%, milk fiber 5%, modal fiber 5%, tea fiber 5%, obtain The yarn count of the twisted yarn is 39Tex, and the cut length of the fiber used is 45mm. The base material and the untwisted yarn are spun on the machine to obtain a super hygroscopic towel with loops on both sides of the base material.

Embodiment 3

[0032] A kind of super hygroscopicity towel and preparation method thereof, the warp thread of bottom material is made of bamboo fiber 46.6%, combed cotton 40%, superfine fiber 13%, resin fiber 0.4% blending, weft thread is made of bamboo fiber 46.5%, combed cotton 41%, 12% superfine fiber, 0.5% resin fiber blend, and blend bamboo fiber and resin fiber, and at 700W, microwave radiation for 6 minutes, blend combed cotton with superfine fiber, and then blend with bamboo fiber resin Terry is the untwisted yarn that obtains by the raw material blending of following weight ratio: bamboo fiber 60%, superfine fiber 15%, combed cotton 10%, milk fiber 5%, modal fiber 5%, tea fiber 5%, obtain The yarn count of the twisted yarn is 40Tex, and the cut length of the fiber used is 48mm. The base material and the untwisted yarn are spun on the machine to obtain a super hygroscopic towel with loops on both sides of the base material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com