PE (polyethylene) modified material and preparation method thereof as well as PE pipe

A modified and recycled material technology, applied in rigid pipes, pipes, mechanical equipment, etc., can solve the problems of PE pipe performance discount, poor compatibility, PE pipe oxidation resistance and tensile strength can not meet market demand, etc. Achieve good antioxidant properties and promote compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

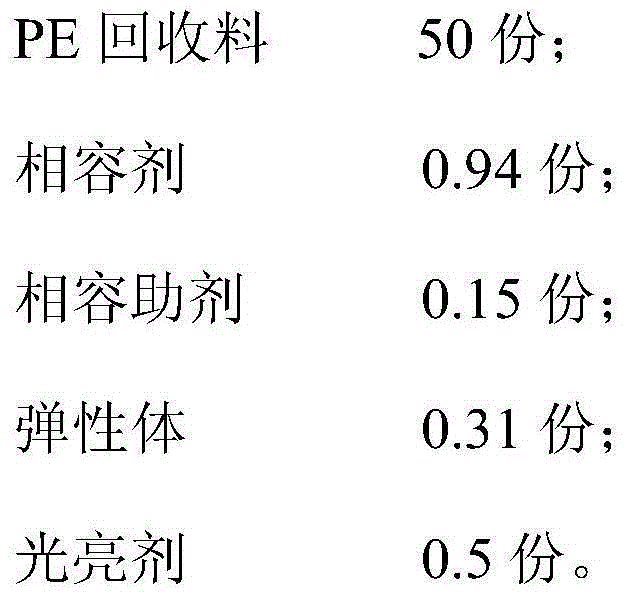

[0037] The formula of PE modified material is as follows:

[0038]

[0039] Put the raw materials of compatibilizer, elastomer, compatibilizer and PE recycled material in a mixer according to weight parts and stir evenly to prepare a blend; introduce the blend into a granulator, Carry out granulation, and then use 80-100 mesh filter screen to filter to obtain PE modified material.

[0040] Mix the dried PE modified material with Jihua 100SPE material at a ratio of 1:1, and add an appropriate amount of color masterbatch to make a PE pipe (the preparation method of the PE pipe belongs to the prior art, and will not be detailed here. described).

Embodiment 2

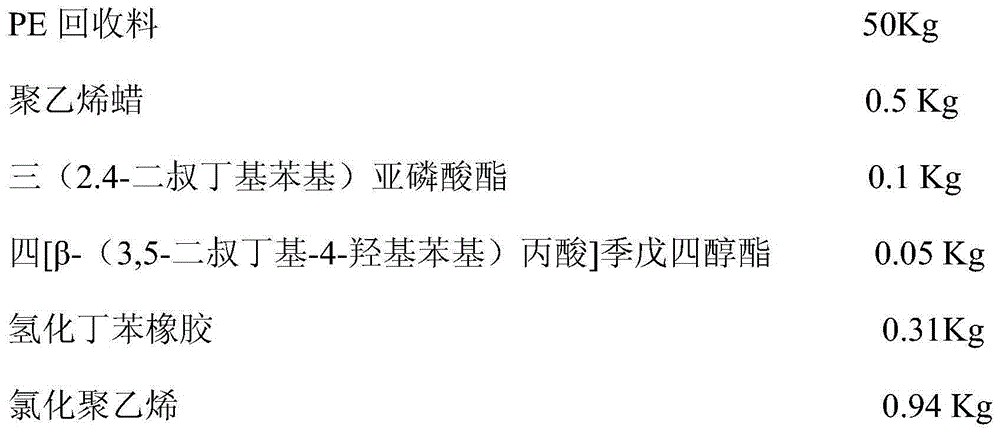

[0042] The formula of PE modified material is as follows:

[0043]

[0044]

[0045] Except for the above formula, the preparation method of the PE modified material and the preparation method of the PE pipe are the same as those in Example 1, and will not be repeated here.

Embodiment 3

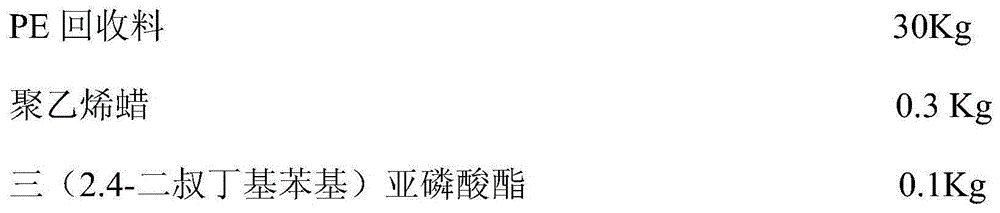

[0047] The formula of PE modified material is as follows:

[0048]

[0049] Except for the above formula, the preparation method of the PE modified material and the preparation method of the PE pipe are the same as those in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com