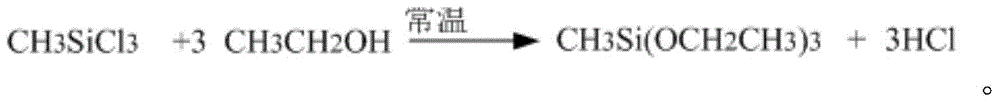

Preparation method of methyl triethoxysilane

A technology of methyltriethoxysilane and methyldichlorosilane, which is applied in the field of preparation of methyltriethoxysilane, can solve the problems of high price, large hydrogen chloride, high production cost, etc., achieve high cost and reduce raw materials The effect of low cost and selling price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

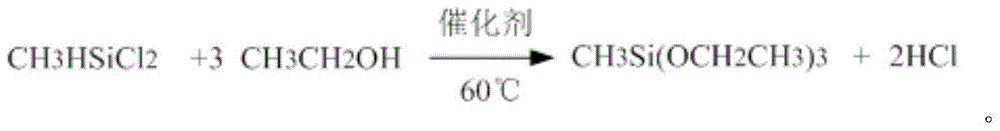

Method used

Image

Examples

Embodiment

[0028] A preparation method of methyltriethoxysilane, the preparation method steps are as follows:

[0029] (1) Methyldichlorosilane and catalyst (anhydrous nickel chloride, according to the weight of methyldichlorosilane, the consumption of anhydrous nickel chloride is 200-2000ppm) are added in the reactor, heated to reflux, Under the condition of stirring, add absolute ethanol dropwise from the bottom of the reaction kettle, and the dropwise addition of absolute ethanol is carried out in two steps: first, add absolute ethanol with a total weight of 30-35% of absolute ethanol dropwise, and control the reaction temperature at 42±1°C. Then the temperature was raised and kept at 60±1°C, and the remaining absolute ethanol was continued to be added dropwise. During the whole process, nitrogen protection is continued, and the molar ratio of methyldichlorosilane to absolute ethanol is 1:3-3.6.

[0030] (2) After all the anhydrous ethanol has been added dropwise, control the reactio...

specific example 1

[0032] Add 1000kg of methyldichlorosilane and 1kg of anhydrous nickel chloride to a 3000L top reactor with a condenser (cooled by -15°C frozen brine) and a stirring tower, and heat to reflux under nitrogen protection . 1440kg of absolute ethanol was added dropwise from the bottom of the kettle. First add 1 / 3 of absolute ethanol, keep the reaction temperature at 42±1°C, then raise the temperature and keep it at 60±1°C, and continue to add the remaining absolute ethanol dropwise. After all the dropwise addition was completed, the reaction was maintained at 60°C for 3 hours. During the reaction, the reaction kettle was controlled to maintain a slight negative pressure environment, and the pressure was kept at -1KPa. Sampling, gas chromatography detection, does not contain methyldiethoxysilane in the product. Then evacuate to -0.08Mpa in the kettle, and keep the top condenser at -15°C and keep full reflux. After 4 hours of reflux, stop vacuuming. During the reflux process, the i...

specific example 2

[0034] Add 1000kg of methyldichlorosilane and 0.7kg of anhydrous nickel chloride to a 3000L top reactor with a condenser (cooled by -15°C frozen brine) and a stirred tower, and heat to reflux under nitrogen protection state. 1380kg of absolute ethanol was added dropwise from the bottom of the kettle. First add 1 / 3 of absolute ethanol, keep the reaction temperature at 42±1°C, then raise the temperature and keep it at 60±1°C, and continue to add the remaining absolute ethanol dropwise. After all the dropwise addition was completed, the reaction was maintained at 60°C for 3 hours. During the reaction, the reaction kettle was controlled to maintain a slight negative pressure environment, and the pressure was kept at -1KPa. Sampling, gas chromatography detection, does not contain methyldiethoxysilane in the product. Then evacuate to -0.08Mpa in the kettle, keep the top condenser at -15°C and maintain total reflux, stop vacuuming after 4 hours of reflux, during the reflux process,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com