Permanent heavy metal waste curing method

A solidification method and waste technology, applied in the field of environmental engineering, can solve the secondary pollution of the surrounding environment, resource waste, uneconomical and other problems, and achieve the effects of solving pollution problems, accelerating utilization, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

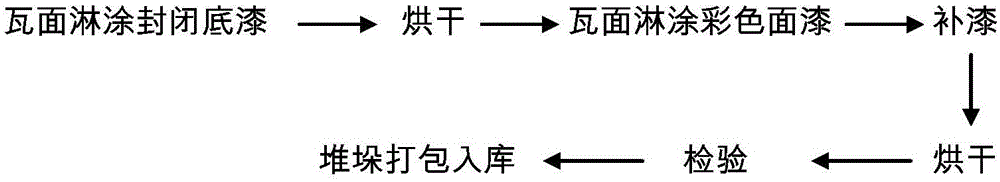

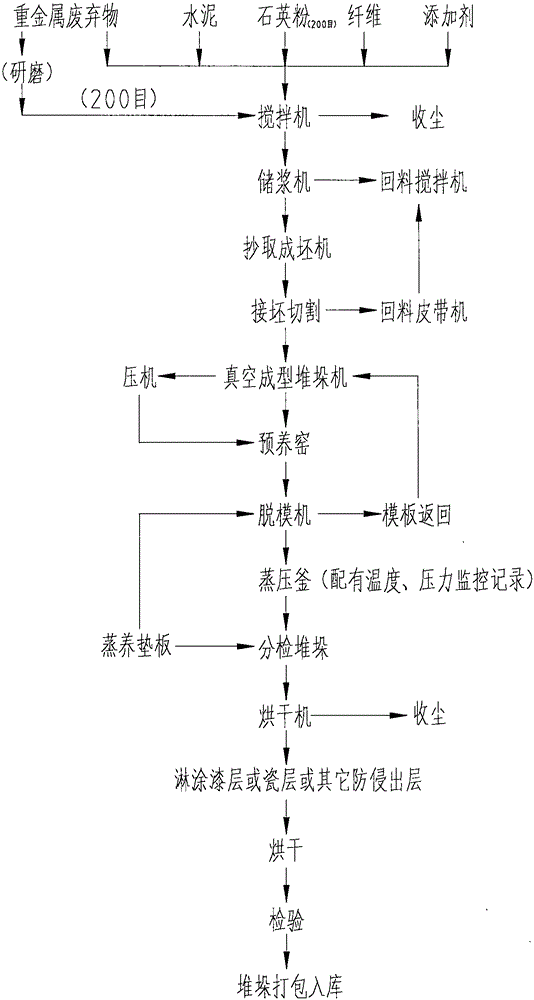

[0034] Embodiment 1: The manufacturing process of the additional product tile by the permanent solidification method of heavy metal waste

[0035] ①Materials: 30% of heavy metal waste, 8% of reinforced fiber, 20% of quicklime, 10% of gypsum, 30% of quartz powder, 1% of additive, and 1% of glass fiber; the fineness of quartz powder is about 200 mesh, and the fineness of heavy metal waste The density is about 80-200 mesh; the above materials can be mixed evenly by mixing equipment and then mixed with water to make pulp, or computer pulping can be used; this embodiment uses computer pulping;

[0036] ②Computerized pulping: use pipeline pumping, screw conveying, belt scales, electronic flow meters, weighing sensors, etc. to automatically pulp the above materials according to the mass ratio, and the pulping concentration is 45%;

[0037] ③Combining into billets: three 180 long tile billets can be produced at one time by using a forming cylinder with a diameter of 1650 mm;

[0038]...

Embodiment 2

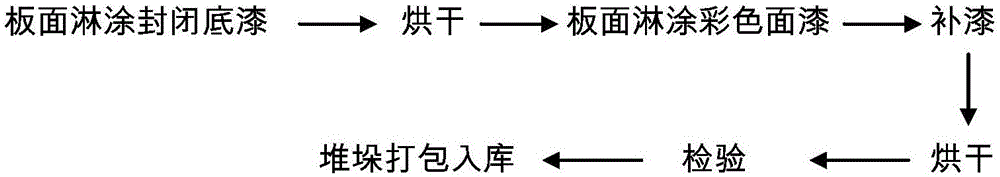

[0047] Embodiment 2: The manufacturing process of the additional product board of the heavy metal waste permanent solidification method

[0048] ①Material ratio: 30% of heavy metal waste pollutants, 20% of quicklime, 10% of gypsum, 30% of quartz powder, 8% of reinforcing fiber, and 2% of additives; the above materials can be mixed evenly by mixing equipment and then mixed with water Pulping can also adopt computerized pulping; this embodiment adopts computerized pulping;

[0049] ②Computer pulping: use pipeline pumping, screw conveying, belt scales, electronic flow meters, weighing sensors, etc. to realize automatic pulping, and the pulping concentration is 45%;

[0050] ③Cutting into billets: Two 2.44-meter-long slabs can be produced at one time by using a forming cylinder with a diameter of 1650 mm;

[0051] ④Vacuum stacking: use a three-station vacuum stacker to realize one board and one mold stacking;

[0052] ⑤ Pressing: Use 14,000 tons of presses to realize the process...

Embodiment example 3

[0061] Implementation Case 3: Manufacturing process of additional product pipe for permanent solidification of heavy metal waste

[0062] ①Materials: 30% of heavy metal waste pollutants, 20% of quicklime, 10% of gypsum, 30% of quartz sand, 8% of reinforcing fibers, and 2% of additives;

[0063] ②Computer pulping: use pipeline pumping, screw conveying, belt scales, electronic flow meters, weighing sensors, etc. to realize automatic pulping, and the pulping concentration is 45%;

[0064] ③Combining and making pipe: use the pipe-taking machine to make a pipe with a diameter of 1 meter, a length of 4 meters and a thickness of 50 mm;

[0065] ④Demoulding: automatic demoulding by electric tube remover;

[0066] ⑤ Pre-curing: static stop maintenance;

[0067] ⑥Steaming: Use a steaming kettle to steam, the temperature of steaming is 197 degrees, and the pressure is 1.3Mp;

[0068] ⑦Stacking pipes: use special cranes or other transportation tools to realize automatic stacking pipes;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com