Nano quantum dot adsorption and film separating system for removing heavy metal in water

A nano-quantum dot and membrane separation system technology, which is applied in the field of nano-quantum dot adsorption and membrane separation systems, can solve the problems of low cross-flow rate of the membrane system, low energy consumption of system operation, and difficult separation of waste water, etc., achieving short hydraulic retention time , The energy consumption of the system is low, and the water quality is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

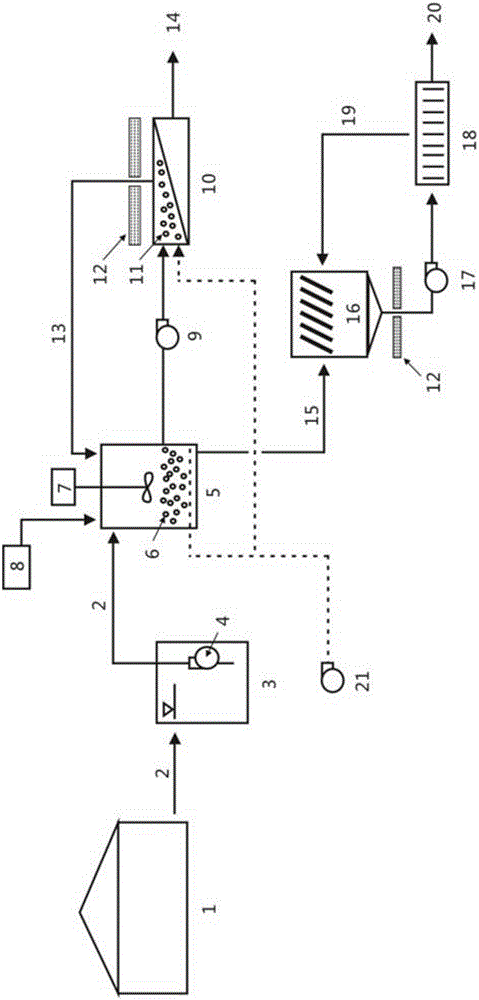

Embodiment 1

[0040] Wastewater containing heavy metals from an electroplating factory in Shanghai, Cr 3+ , Cu 2+ , Ni + The concentration of the air is 0.84ppm, 211ppm and 3.1ppm respectively. After 10min of adsorption reaction, the air volume of fine aeration is 50L / min / m 2 The bottom area of the pool, the stirring speed is 100rpm, the mixed liquid enters the membrane system for separation, the membrane filtration system uses a tubular ultrafiltration membrane with a separation pore size of 0.05μm, the membrane material is PVDF, the flow rate in the tube is 1.5m / s, and the amount of fine air scrubbing 2L / min / m 2 Membrane area, Cr in permeate water 3+ , Cu 2+ , Ni + The concentrations were 0.0184ppm, 0.0464ppm, and 0.0367ppm, respectively.

Embodiment 2

[0042] Wastewater containing heavy metals from a metal surface treatment company in Anhui, Zn 2+ , Mn 2+ , Ni + The concentrations are 68.6ppm, 54.3ppm, and 53.9ppm, respectively. After 30min of adsorption reaction, the air volume of fine aeration is 100L / min / m 2 The bottom area of the pool, the stirring speed is 50rpm, the mixed liquid enters the membrane system for separation, the membrane filtration system uses a tubular microfiltration membrane with a separation pore size of 0.1μm, the membrane material is ceramic, the flow rate in the tube is 2m / s, and the volume of fine air scrubbing is 1L / min / m 2 Membrane area, Zn in permeate water 2+ , Mn 2+ , Ni + The concentrations were 0.0052 ppm, 0.00312 ppm, and 0.0153 ppm, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com