A production equipment for continuously coating ultra-high molecular weight polyethylene on sucker rods

An ultra-high molecular weight, production equipment technology, applied in the field of continuous coating of small diameter parts of standard sucker rods, can solve the problems of large coating thickness, increased production cost, short service life of sucker rods, etc., and achieve excellent corrosion resistance , Improve the anti-wear and anti-scaling performance, the effect of blocking corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

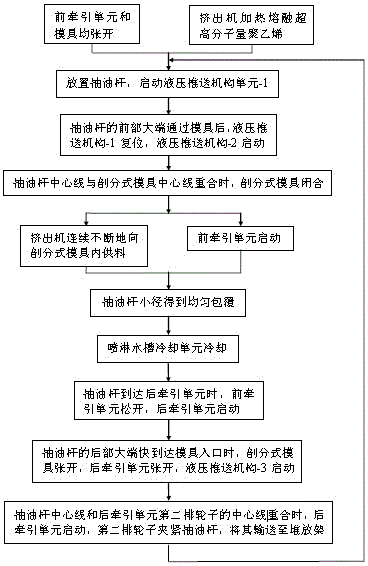

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

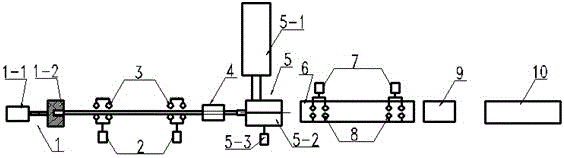

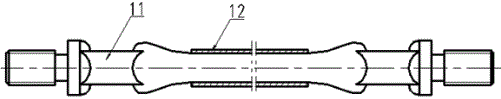

[0025] Such as figure 1 As shown, a production equipment for sucker rods continuously coated with ultra-high molecular weight polyethylene, the processed sucker rods are standard sucker rods of ϕ22mm, the diameters of the two ends of the sucker rods are large, the diameter of the middle is small, and the maximum diameter is ϕ41.3mm, the minimum diameter is ϕ22mm, the total length is 8m, and the cladding thickness is required to be 2mm. The cladding effect is as follows image 3 shown. The continuous coating production equipment of the sucker rod consists of hydraulic pushing mechanism unit-1 (1), hydraulic pushing mechanism unit-2 (2), fixed limit wheel-1 (3), front traction unit (4), extrusion Coating unit (5), spray tank cooling unit (6), hydraulic push mechanism unit-3 (7), fixed limit wheel-2 (8), rear traction unit (9) and stacking frame (10), The above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com