Method for preparing shaving board by using Jujuncao

A technology of giant juncao and shavings, applied in the field of giant juncao, can solve the problems of unstable raw material quality, unsuitable for large-scale purchase, and large-scale raw material purchase, so as to improve product qualification rate and subsequent processing performance, and solve the problem of plate production Industrialization problems, the effect of solving raw material shortage and uncertainty problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

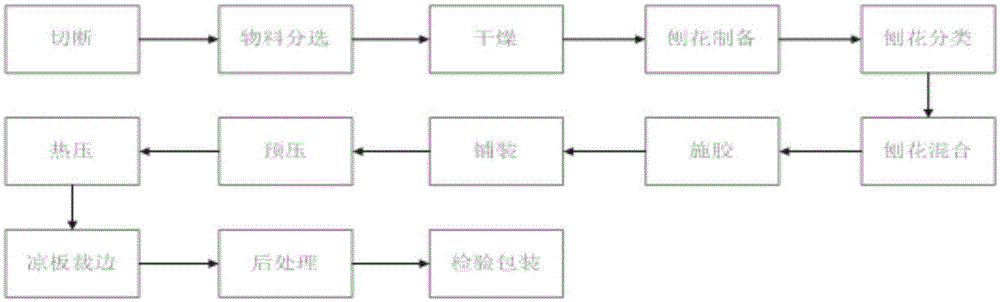

Image

Examples

Embodiment 1

[0028] All shavings are prepared from giant fungus

[0029] (1) Cutting and sorting: 1,000 kg of giant fungus grass is cut into a unit length of 5-50 mm by a grass cutter, and impurities and small leaves in giant fungus grass are sorted out according to the principle of heavy object sorting. And carry out drying and sterilization treatment at a temperature of 100-200°C, and control its moisture content between 18-20%;

[0030] (2) Preparation of shavings: Put the cut giant fungus grass into the pulverizer for primary powder, then enter the ring grinder for fine grinding, and then classify and sieve into 50% surface shavings and 50% core shavings. Drying, the moisture content of surface shavings is 18.0%, and the moisture content of core shavings is 12.0%;

[0031] (3) Sizing: Sizing the surface shavings and core planing respectively;

[0032] Firstly, the weight of the surface and core layer shavings is measured respectively through the belt weighing conveyor and the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com