Six-face machining tool and six-face machining method of diesel engine body

A technology for diesel engine and surface processing, applied in the field of machine tools, can solve the problems of different processing fineness, high labor consumption, low processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

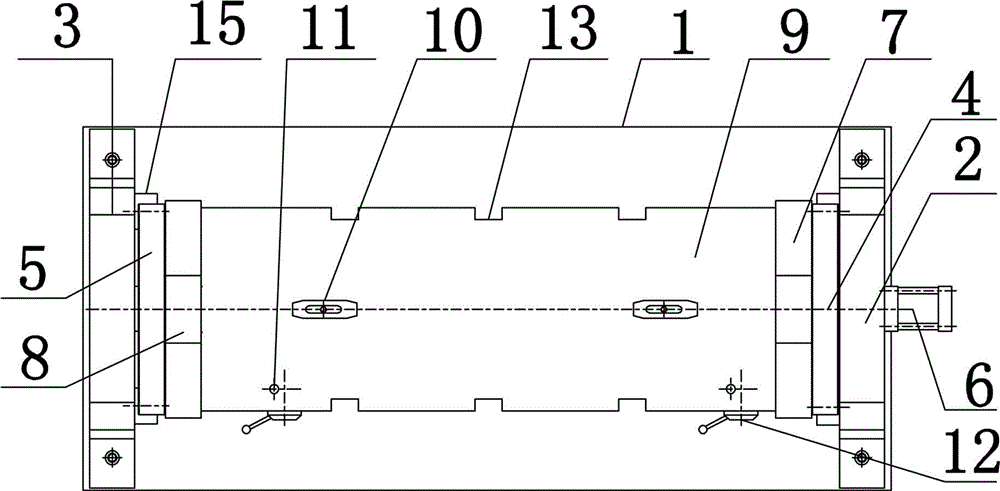

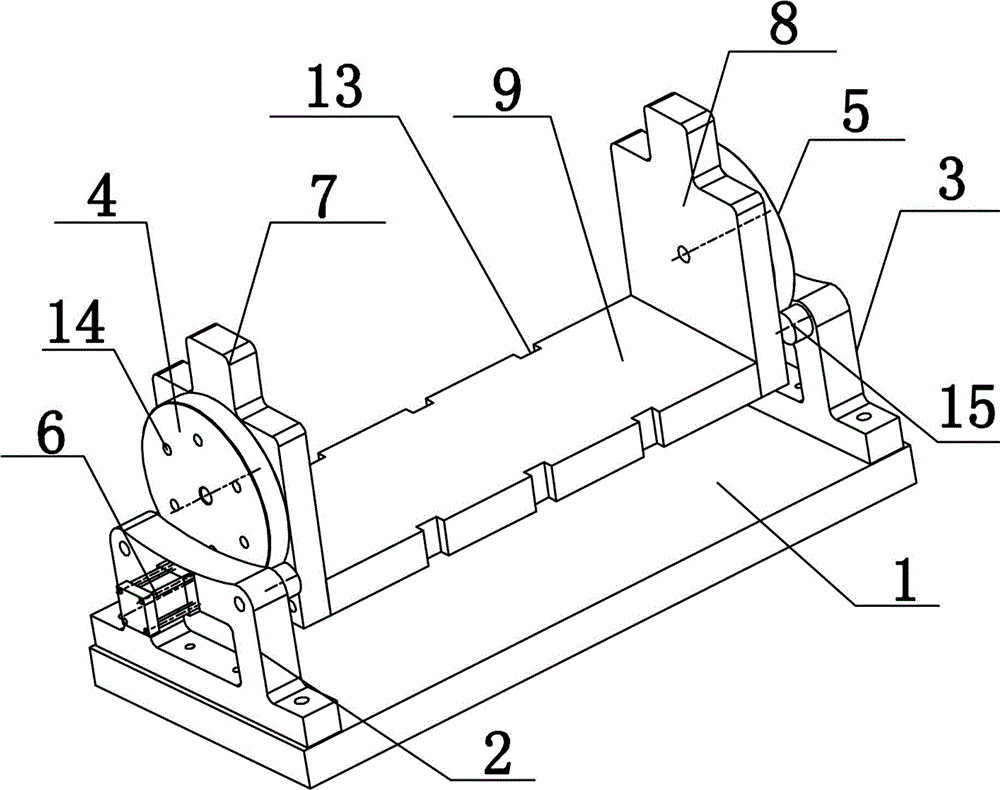

[0020] As shown in the figure, the present invention relates to a six-sided processing tool for a diesel engine body, including a base 1, and the two ends of the base 1 are respectively provided with a front disc support 2 and a rear disc support 3, and the front disc The support 2 and the rear end disc support 3 are respectively connected with a front end rotating disk 4 and a rear end rotating disk 5; a rotating table is arranged between the front end rotating disk 4 and the rear end rotating disk 5, and a number of positioning plates are arranged on the rotating table. mechanism: an air pump 6 is provided on the outside of the front-end disk support 2 or the rear-end disk support 3, and positioning pins are arranged in the air pump 6, and the air pump 6 and the front-end rotating disk 4 or the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com