Iron separating method for metamorphic iron tailings

A technology for iron tailings and iron separation, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as land occupation, waste of resources, environmental pollution, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

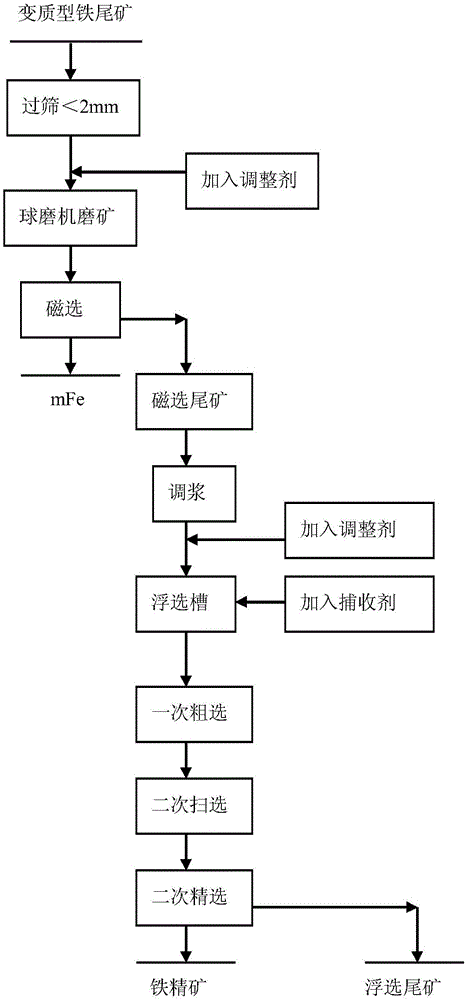

Method used

Image

Examples

Embodiment 1

[0036] Take 1000g of metamorphic iron tailings in Liaoning and sieve < 2mm, add 40g / t sodium silicate and 5g / t sodium chloride in sequence, grind to -0.074mm magnetic separation, magnetic separation mFe, magnetic separation tailings to adjust ore slurry to 20%, then add 25g / t sodium carbonate and 40g / t non-polar oil in sequence, stir for 3.5min, enter the flotation tank, add oleic acid 80g / t, roughen for 5.5min, sweep once for 5min, and sweep twice 4.5 minutes, 5 minutes for the first selection, and 3 minutes for the second selection. The obtained iron ore concentrate has a grade of 59.9% and a recovery rate of 90%.

Embodiment 2

[0038] Take 1000g of a metamorphic iron tailings in Hebei that is screened <2mm, add 30g / t sodium silicate and 8g / t sodium chloride in sequence, grind to -0.074mm, magnetically separate mFe, and adjust the slurry to 20 %, sequentially add sodium carbonate 30g / t, non-extreme oily oil 30g / t, stir for 4.5min, enter the flotation tank, add oleic acid 100g / t, roughing for 5.5min, first sweeping for 5min, second sweeping for 4.5min, The first beneficiation is 4 minutes, and the second beneficiation is 3 minutes, the grade of iron concentrate is 60.8%, and the recovery rate is 90.06%.

Embodiment 3

[0040] Take 1000g of metamorphic iron tailings in Jilin that are screened <2mm, add 45g / t sodium silicate and 10g / t sodium chloride in sequence, grind to -0.074mm, magnetically separate mFe, and adjust the slurry to 20 %, add sodium carbonate 30g / t, non-polar oil 50g / t in turn, stir for 4 minutes, enter the flotation tank, add oleic acid 105g / t, sweep for 5 minutes once, sweep twice for 4.5 minutes, and refine for 4 minutes once, The secondary concentration was carried out for 3 minutes, and the grade of iron concentrate was 62.9%, and the recovery rate was 150%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com