Constant velocity joint

A universal joint, circumferential direction technology, used in elastic couplings, couplings, mechanical equipment, etc., can solve problems such as increasing the friction of universal joints, reduce friction surface and friction power, simple cost, Weight saving and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

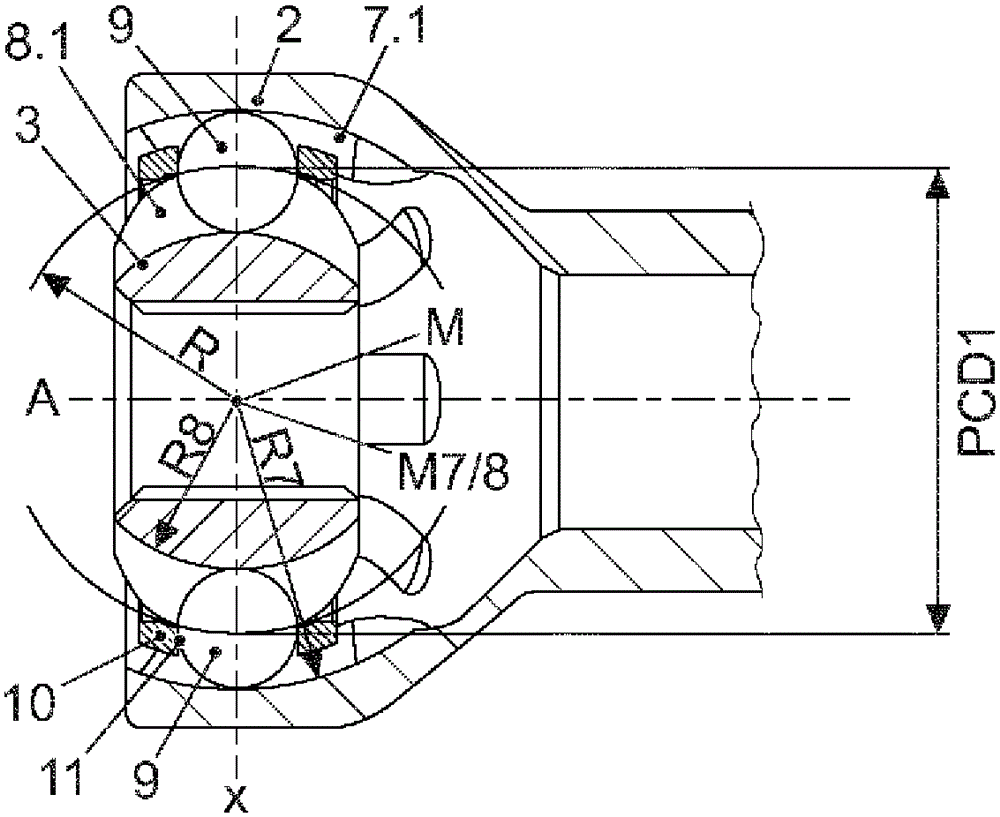

[0034] The exemplary embodiment shows a synchronous joint 1 with two joint components, a joint outer part 2 and a joint inner part 3 .

[0035] The joint inner part 3 is arranged in the bell-shaped outer joint part 2 and has an internal toothing for a coupling shaft or the like.

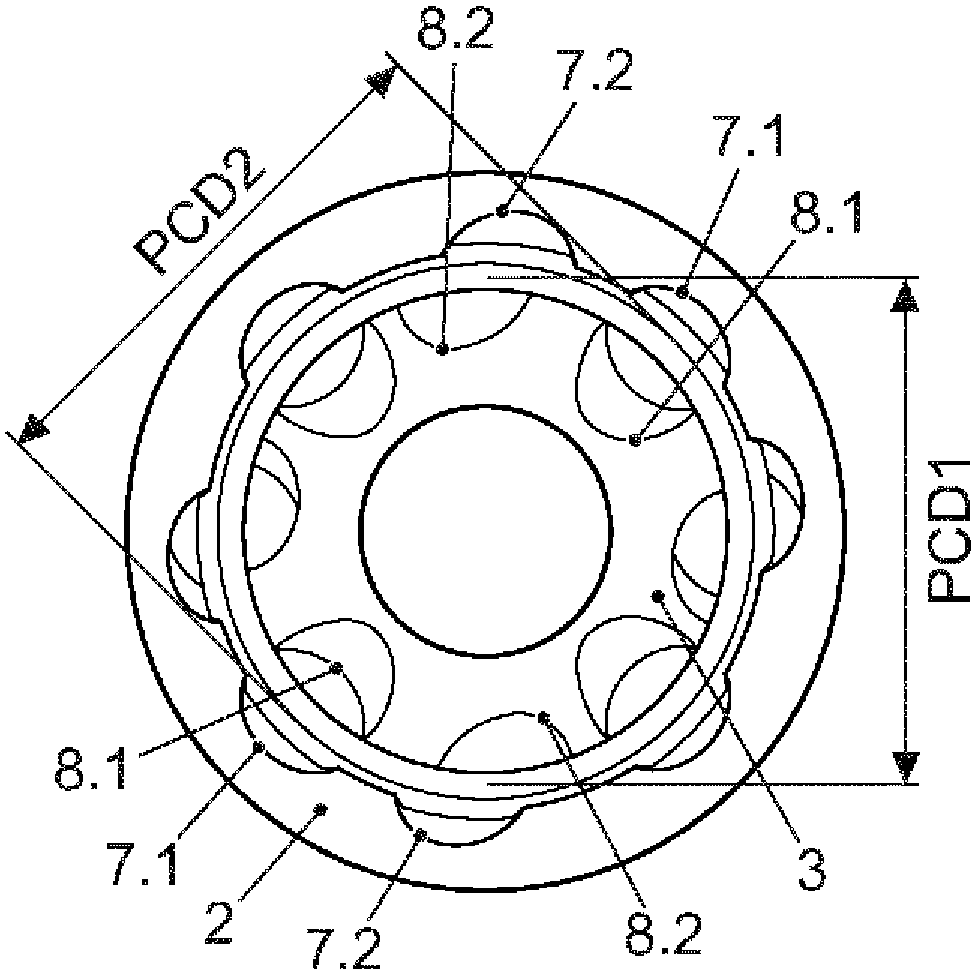

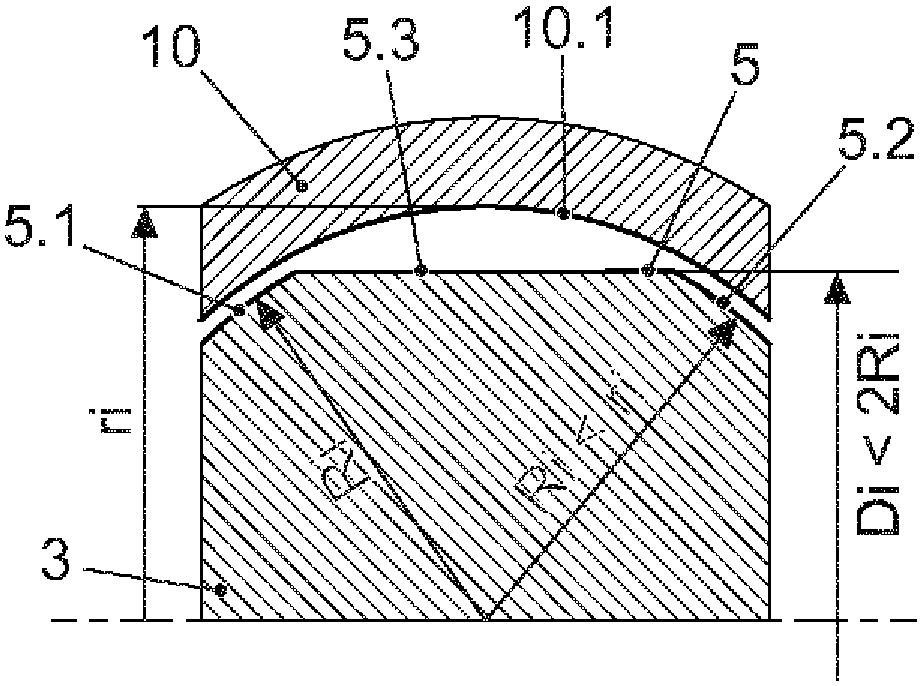

[0036]On the inner circumference 4 of the joint outer part 2 and on the outer circumference 5 of the joint inner part 3 respectively a large number of, for example eight or sixteen ball raceways 7 and 8 are formed, which are formed accordingly. facing each other. The ball raceway 7 on the joint outer part 2 and the ball raceway 8 on the joint inner part 3 respectively form a ball raceway pair. Balls 9 are respectively accommodated in each ball raceway pair.

[0037] Furthermore, a retaining ring 10 is arranged between the joint outer part 2 and the joint inner part 3 , which retainer has a plurality of windows 11 at its periphery. Balls 9 are arranged in each of these windows 11 , which are held i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com