Centrifugal pump of asynchronous-starting permanent-magnet-synchronous motor

A permanent magnet synchronous and asynchronous starting technology, applied in the field of centrifugal pumps, can solve problems such as low efficiency and backward technology, and achieve the effect of improving motor efficiency, unit efficiency and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

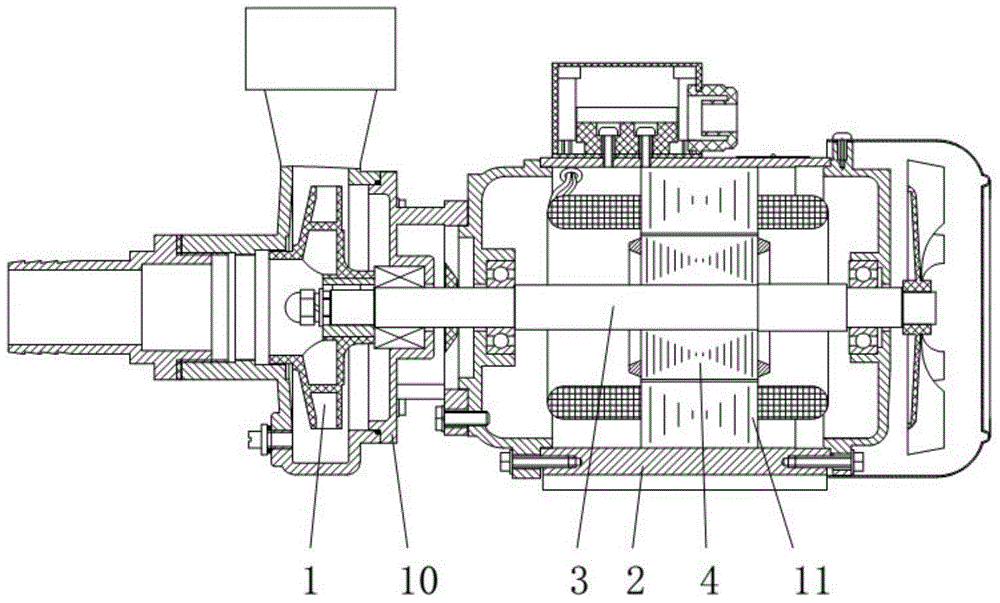

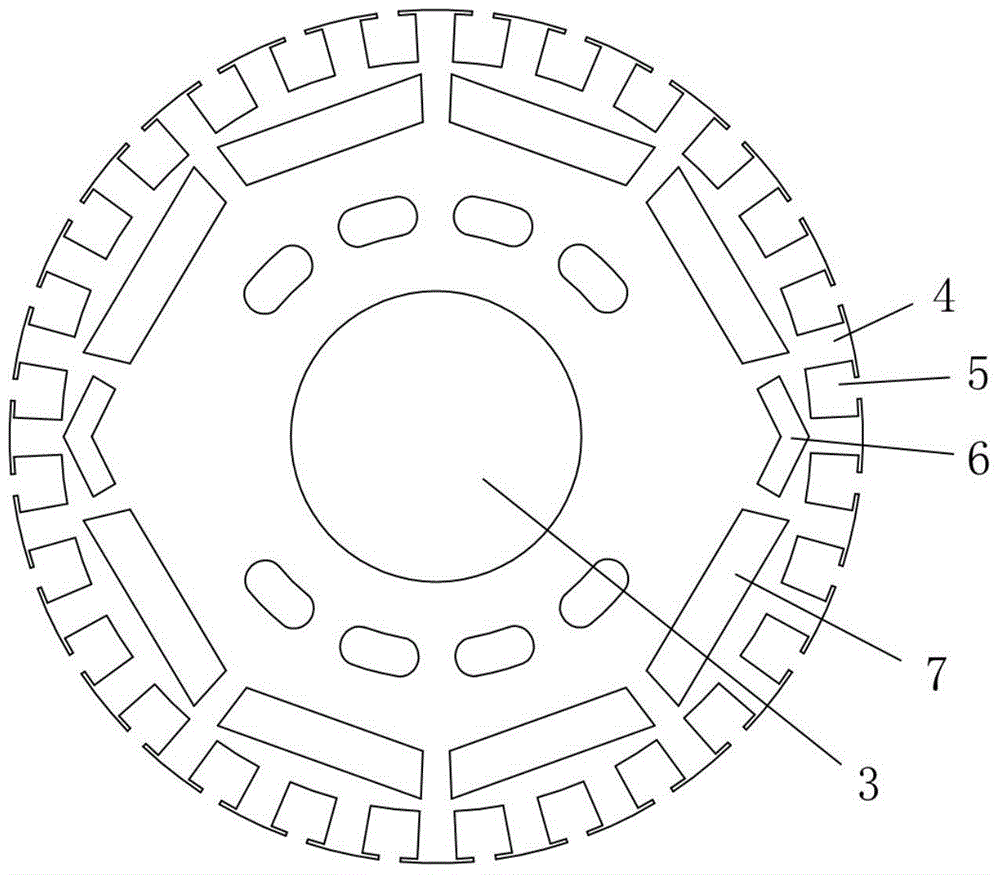

[0028] An asynchronous start permanent magnet synchronous centrifugal pump, including a pump body 10 and a motor 2, the motor includes a stator and a rotor, the stator is basically the same as the stator of a three-phase asynchronous motor, and the rotor includes a rotating shaft 3 in the center and a sleeve The rotor core 4 on the rotating shaft is composed of a plurality of circular silicon steel sheets axially superimposed on the rotating shaft. A plurality of guide bar windings 5 are evenly inserted in the circumferential direction of the rotor iron core. All guide bars The winding 5 forms a circular squirrel cage structure;

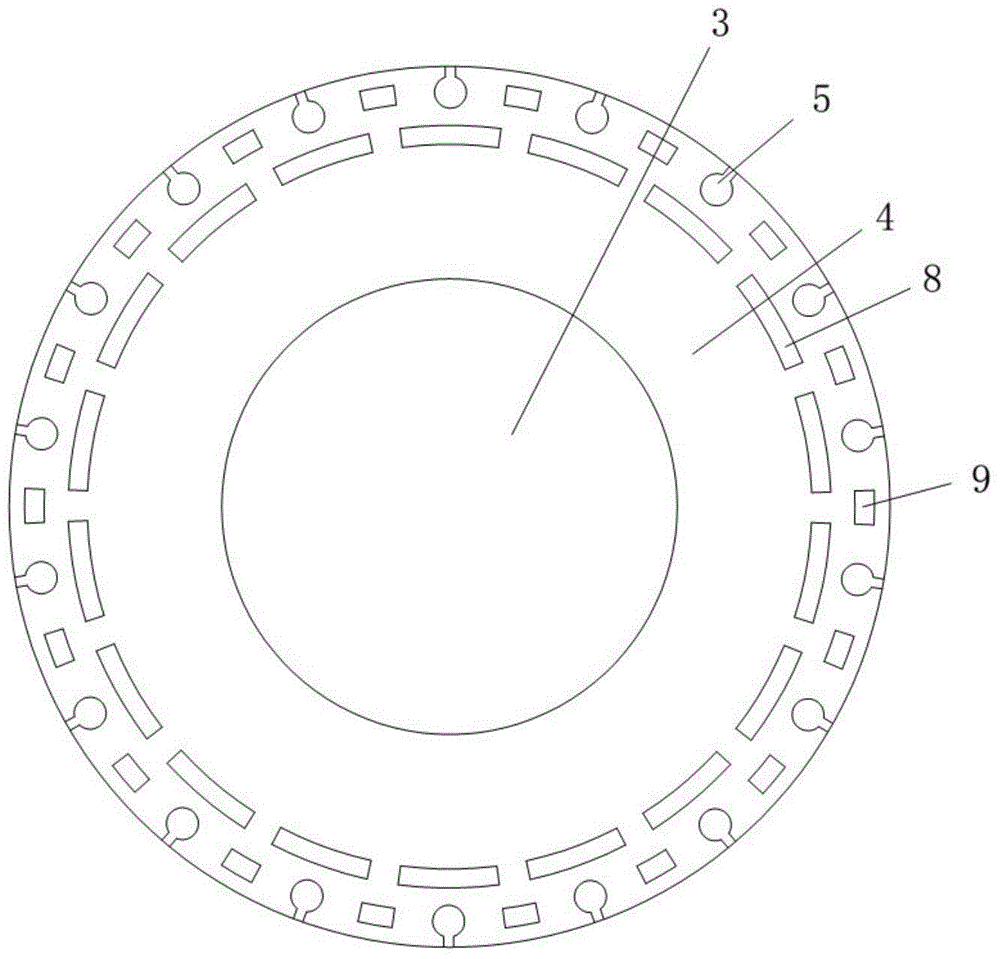

[0029] One or two sets of permanent magnets 7 are arranged on the rotor core. The permanent magnets are arranged symmetrically on the sides of the rotating shaft 3 and overlap with the circular squirrel cage. The permane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com