Nano Vacuum Triode Structure and Preparation Method of Inverted Anode

A vacuum triode, anode technology, applied in cold cathode manufacturing, electrode system manufacturing, non-electron emission anode and other directions, can solve the problem of difficult to overcome cathodic oxidation, insufficient collection capacity of device leakage anode, affecting the development and application of aluminum nitride vacuum triode, Insufficient anode collection capacity and other problems, to achieve the effect of reducing manufacturing difficulty, reducing oxidation, and reducing process treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

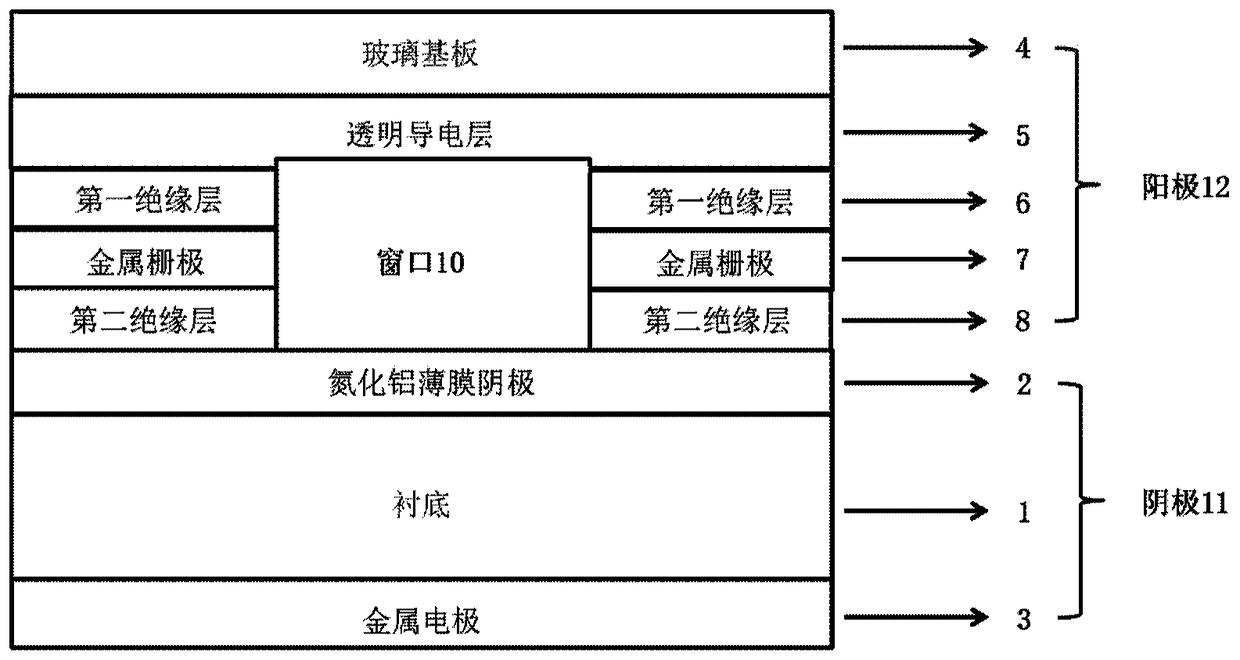

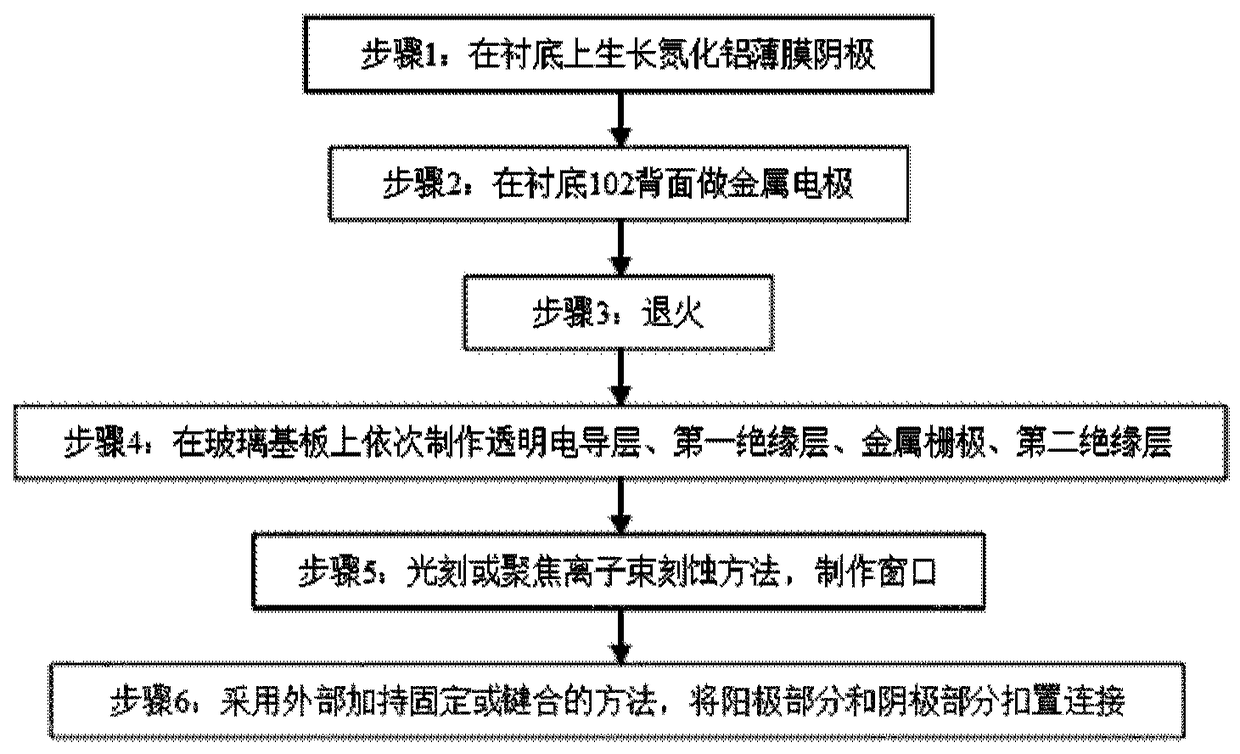

[0030] see figure 1 As shown, the present invention provides a nano-vacuum triode structure with an inverted anode, comprising:

[0031] A substrate 1, which can be semi-insulating sapphire or silicon carbide, with a resistivity of 0.03-0.04Ω·cm and a thickness of 300-450μm;

[0032] An aluminum nitride thin film cathode 2, the aluminum nitride thin film cathode 2 is grown on the front side of the substrate 1 by MOCVD method, the aluminum nitride thin film cathode 2 is doped with n-type Si, and the Si doping concentration is 1×10 18 cm -3 -1×10 21 cm -3 , the thickness is 50nm-500nm;

[0033] A metal electrode 3, the metal electrode 3 is made on the back of the substrate 1, and a layer of Ni / Au alloy is first made on the back of the substrate 1 by PECVD or sputtering method, and the Ni / Au alloy is formed with the substrate 1 after annealing Good ohmic contact, the thickness of Ni and Au is divided into 50nm and 50nm, the annealing temperature is 950°C-1050°C, the annealin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com