A Method for Determining Optimum Height of Workpiece Table Detector of Photolithography Machine

A determination method and photodetector technology, applied in the field of semiconductors, can solve problems such as limited resolution and long measurement time, and achieve the effects of high measurement accuracy, fewer iterations, and fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A method for determining the optimal height of the workpiece stage detector of a lithography machine according to the present invention will be further described in detail below.

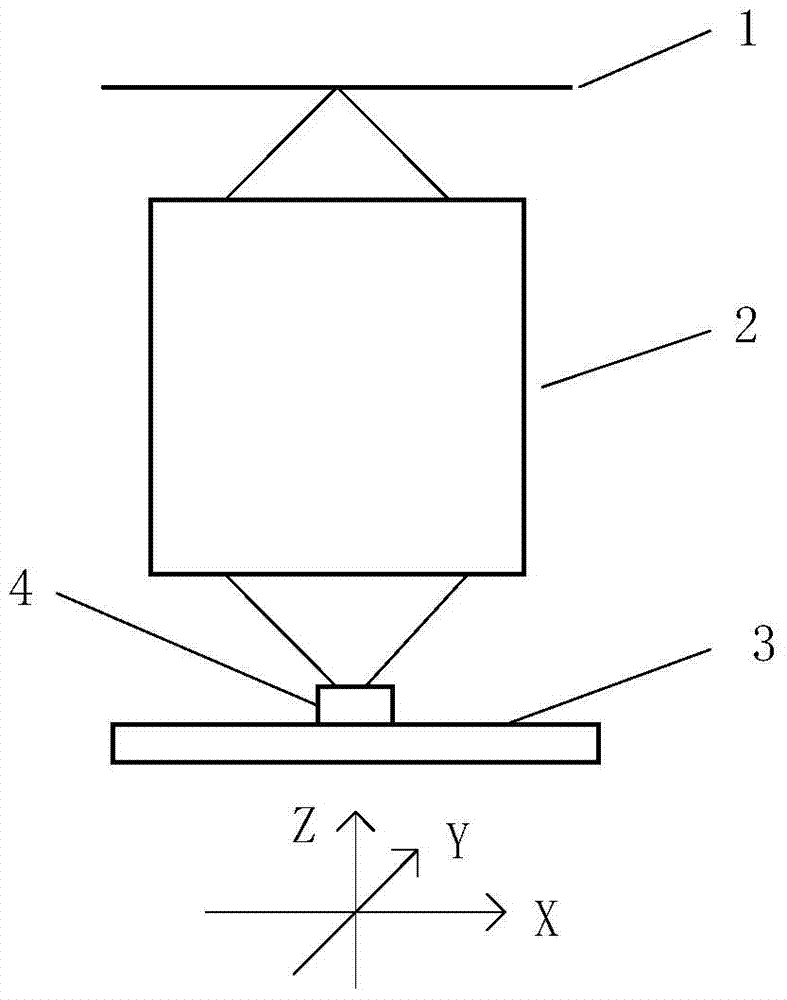

[0026] figure 1 Shown is a schematic diagram of an optimal height measurement device for the photodetector of the workpiece table of the lithography machine. The exposure system of the lithography machine is provided with an illumination system, a mask 1 with a light-transmitting area, a projection objective lens 2 and a workpiece table 3 in sequence along the optical axis. The illumination system illuminates the mask 1 and images it on the workpiece table through the projection objective lens 2. The photodetector 4 is installed on the workpiece table. The workpiece table can perform three-dimensional scanning and drive the photodetector to detect the transmitted light intensity signal.

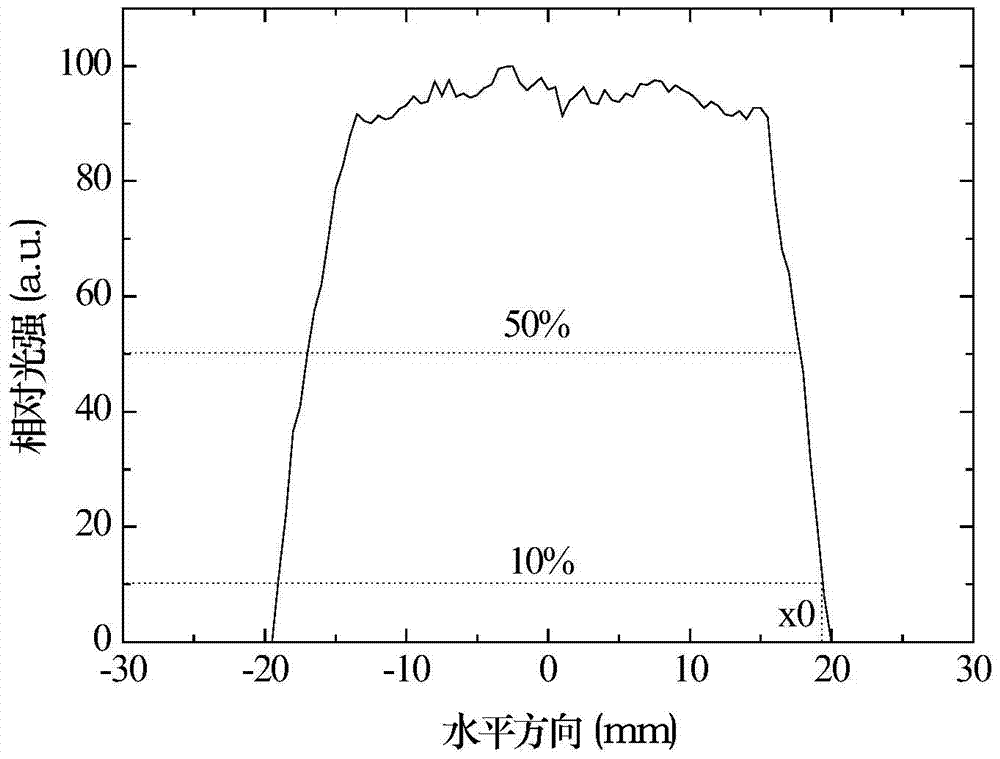

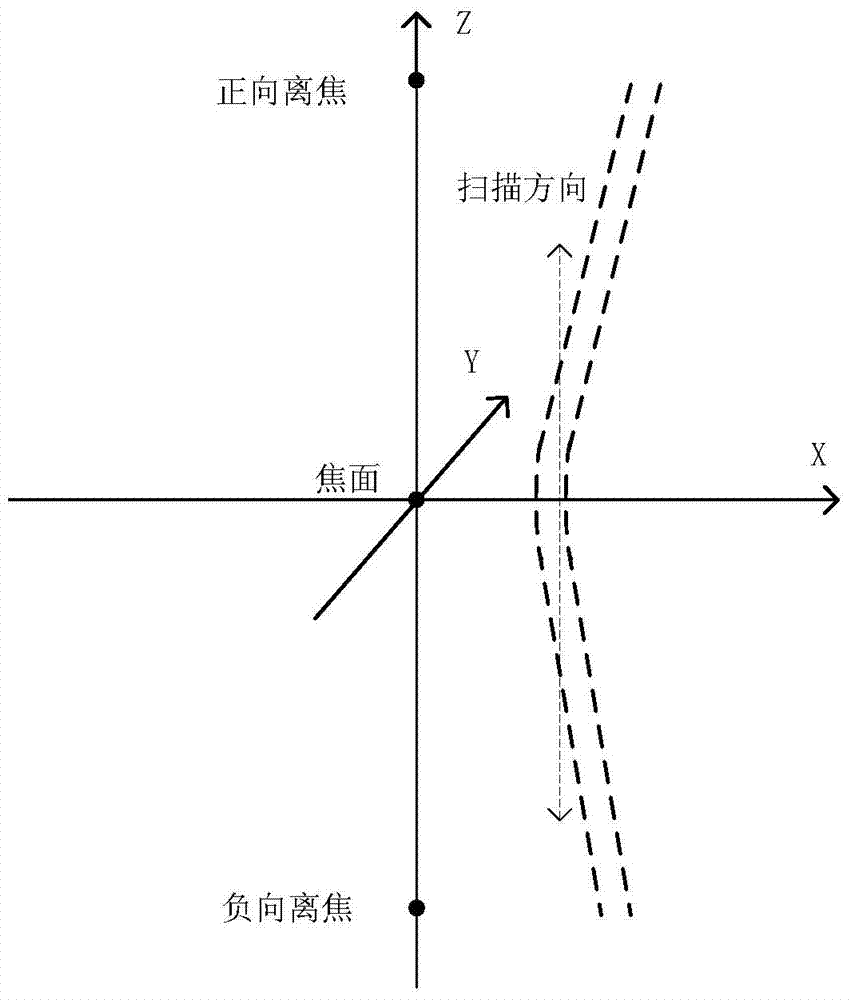

[0027] for figure 1 Shown device, application of the present invention determines the method for photod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com