Measurement method for calculating two-phase transition ratio by thermal expansion curve

A measurement method and technology of thermal expansion, which is applied in the field of metal phase transition measurement, can solve problems such as the influence of accurate calculation of phase transition ratio, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

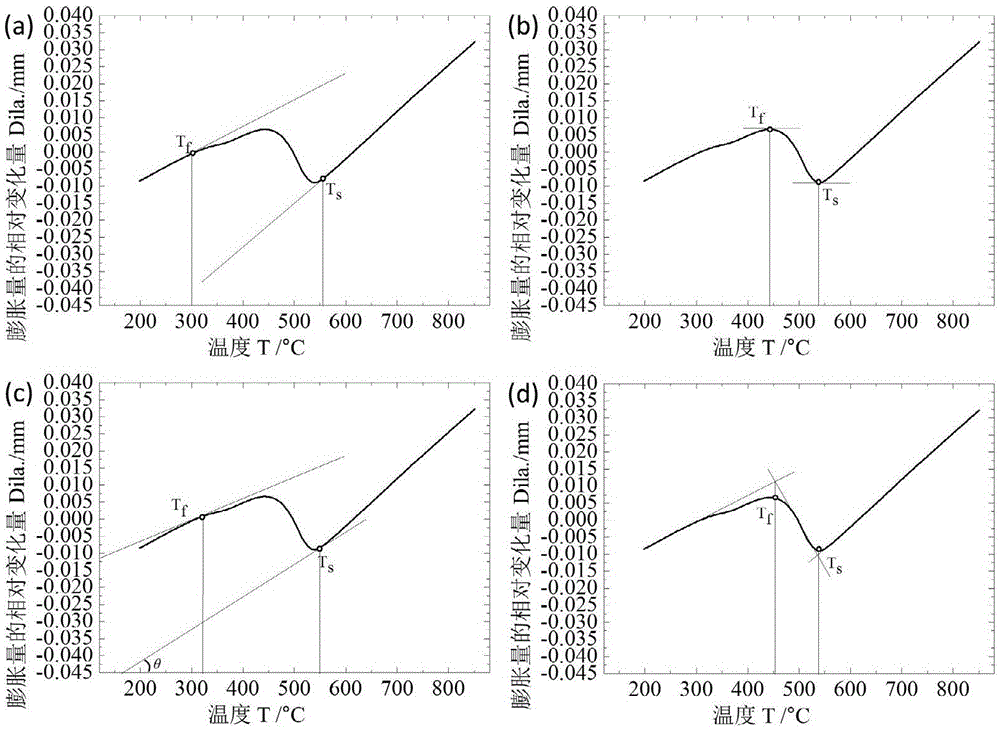

Method used

Image

Examples

Embodiment Construction

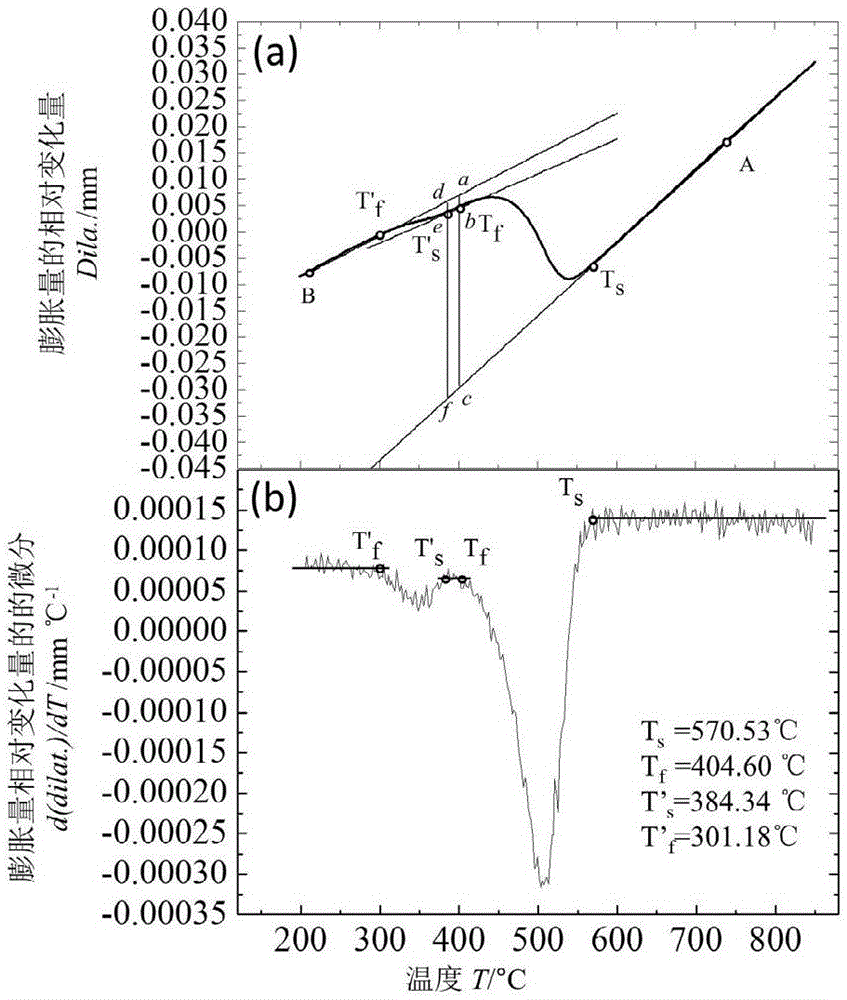

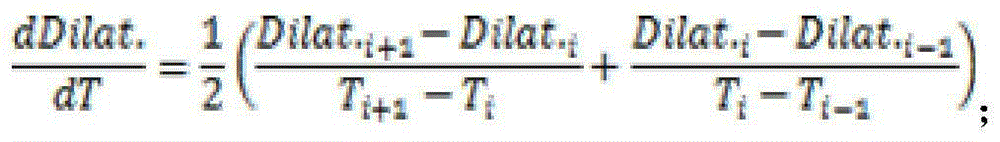

[0019] This example provides a numerical value of the relative change in thermal expansion as a function of temperature measured by GLEEBLE3500 under the condition of a cooling rate of 10°C / s, where the accuracy of the relative change in thermal expansion reaches 10 -6 mm with a temperature accuracy of 10 -2 °C, the obtained relative change curve of thermal expansion is as follows figure 2 (a) shown. Numerically differentiating the relative change in thermal expansion is calculated as follows:

[0020] ;

[0021] Among them: i is time; Dilat., Dilat.i, Dilat.i-1, Dilat.i+1 are the relative changes in thermal expansion over time; Ti, Ti+1, Ti-1 are the temperature of materials changing with time value. Get the differential curve of relative change in thermal expansion, such as figure 2 (b). pass figure 2 (b) Obtain phase transition temperature data, as shown in the figure, Ts=570.53°C, Tf=404.60°C, T's=384.34°C, T'f=301.18°C. It can be seen that compared with the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com