Container volume measurement device and measurement method based on secondary micro-variation allowance pressure principles

A technology of differential pressure sensor and container, which is applied in the direction of volume measuring instrument/method, container/cavity capacity measurement, measuring device, etc., and can solve the problems of fast, accurate and non-destructive measurement of complex structure container volume, complicated process and slow process and other problems, to achieve the effect of shortening the thermal equilibrium time, rapid measurement, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

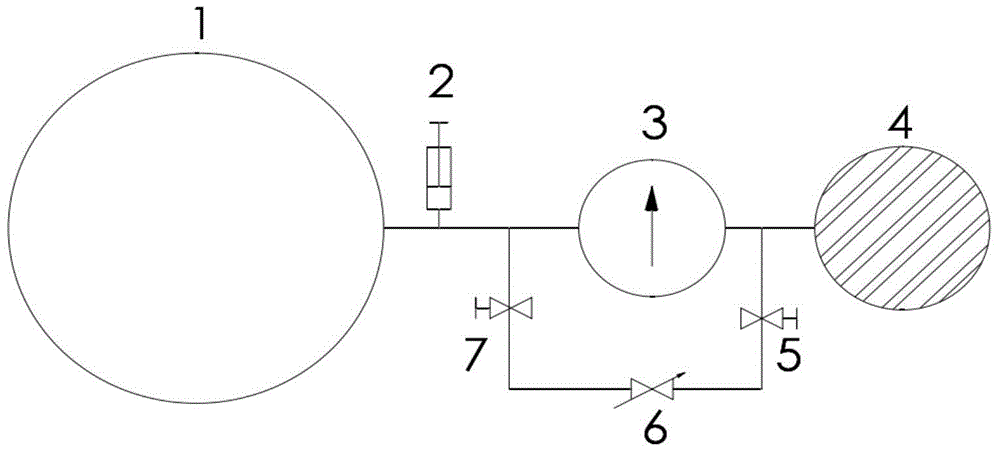

[0016] Embodiment 1, container volume measuring device based on the principle of secondary micro-variable differential pressure, such as figure 1 As shown, the measured container 1 is included, and the measured container 1 is sequentially connected to the differential pressure sensor 3 and the isothermal reference container 4 filled with thin copper wires uniformly distributed inside through the pipeline; the measured container 1 is connected to the differential pressure sensor The precision piston 2 is set in the pipeline between 3, one end of the left valve 7 is connected to the left end of the needle valve 6, and the other end is connected to the pipeline between the differential pressure sensor 3 and the precision piston 2; one end of the right valve 5 It is connected to the right end of the needle valve 6, and the other end is connected to the pipeline between the isothermal reference container 4 and the differential pressure sensor 3.

Embodiment 2

[0017] Embodiment 2, the measuring device described in embodiment 1 is used for the measuring method of container volume, and described measuring method comprises the following steps: 1, the measuring device is connected successively, and the sealing position compression of pipeline will make differential pressure There is a certain pressure difference on both sides of the sensor 3; 2. Open the left valve 7, the needle valve 6, and the right valve 5 in sequence to communicate with the container 1 under test and the isothermal reference container 4, so that the pressure difference on both sides of the differential pressure sensor 3 is returned to zero; 3. Close the needle valve 6 and read the reading of the differential pressure sensor 3 as Δp 0 , that is, the background pressure difference; 4. Adjust the precision piston 2 to perform the first micro-variation of the tested container 1, and the volume change is ΔV 1 , read the reading change value Δp of the differential pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com