Detection system and method of coating membrane thickness

A detection system and detection method technology, applied in the field of detection, can solve the problems of product quality and yield improvement due to changes in confirmation time and process parameters, lag in film thickness inspection, etc., to achieve timely and rapid detection timeliness, monitoring stability, Responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The word "embodiment" as used in this specification means serving as an example, instance or illustration. Furthermore, the article "a" as used in this specification and the appended claims may generally be construed to mean "one or more" unless specified otherwise or clear from context to refer to a singular form.

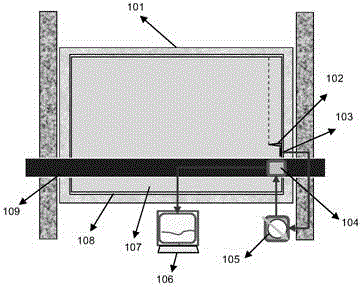

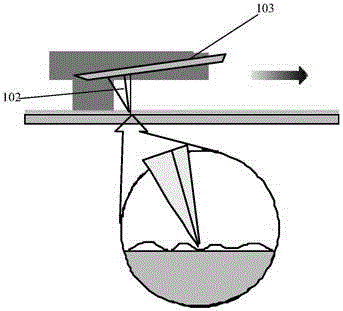

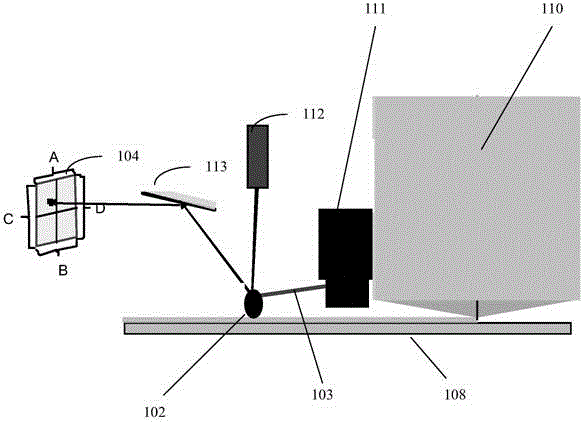

[0039] In the embodiment of the present invention, in order to avoid the hysteresis of coating film thickness measurement, a coating film thickness detection system of a non-contact micro-cantilever probe is designed to measure the change of film thickness in real time during the coating process , the system is directly erected on the linerguide on the side of the coating machine frame (Gantry), and can move laterally for measurement at the same time, and move to the back end of the coating nozzle (Nozzle) during real-time online measurement, the detection and coating of PR film thickness The cloth process is carried out synchronously, and the surface state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com