Mechanical seal device with seal rings with controllable cone bevel seal end faces

A mechanical sealing device and sealing end technology, applied in mechanical equipment, engine sealing, engine components, etc., can solve the problems of difficult surface taper, inability to adjust, and change in the size of the taper angle of the seal end face, and achieve high rigidity and bearing capacity. ability, reduced cost and difficulty, reduced effect of surface deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

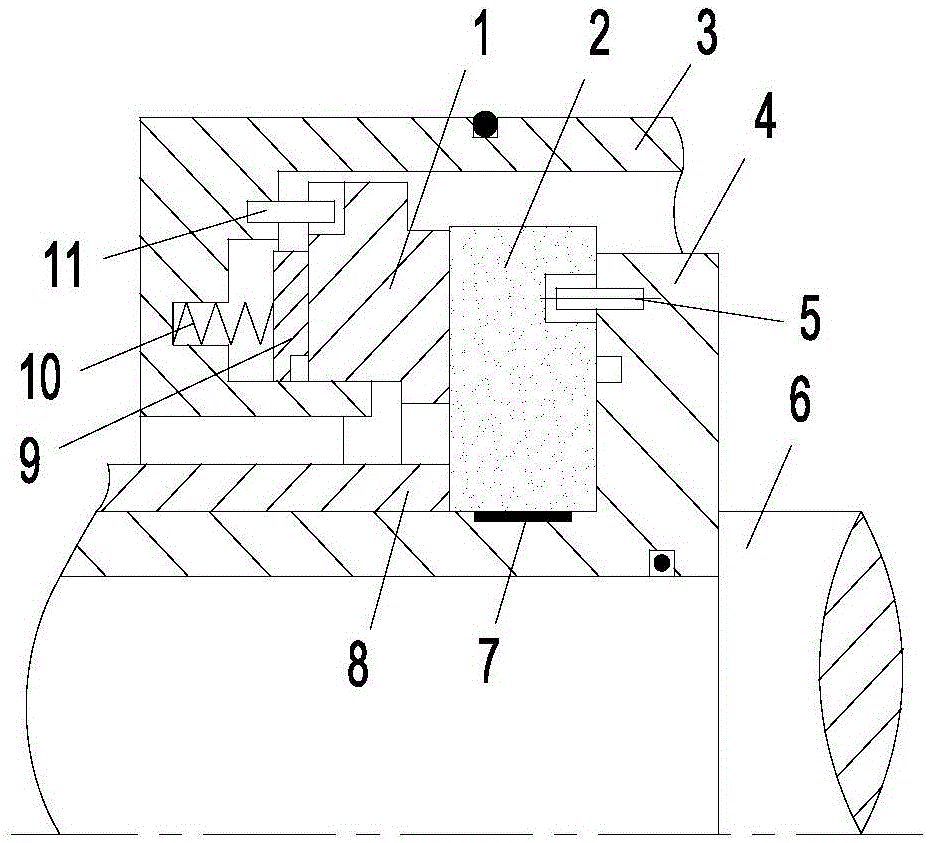

[0022] Such as figure 1Shown is the basic structural form of the mechanical seal device commonly used at present, with a static ring 1, a moving ring 2, a static ring seat 3, a shaft sleeve 4, a transmission pin 5, a tolerance ring 7, a compression sleeve 8, a push ring 9. The spring 10 and the anti-rotation pin 11 are components. The static ring 1 and the moving ring 2 are arranged coaxially opposite each other, and their opposite end surfaces are sealing surfaces. Static ring 1 is radially vacantly sleeved on static ring seat 3, axially supported by push ring 9 and spring 10, and circumferentially positioned by anti-rotation pin 11, so that static ring 1 can only freely float axially. The moving ring 2 is radially expanded by the tolerance ring 7 on the outer cylindrical surface of the shaft sleeve 4, axially contacts with the stepped surface of the shaft sleeve 4 and is compressed axially by the compression sleeve 8, and is circumferentially connected by the transmission p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com