Noise reduction type gas turbine gas intake system for low-temperature environment

A gas turbine and air intake system technology, which is applied in the directions of gas turbine devices, jet propulsion devices, mechanical equipment, etc., can solve the problems of icing, unsatisfactory purification and drying effect, and high inlet noise of the air intake system. To achieve the effect of simple structure, strong practicability and guaranteed purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

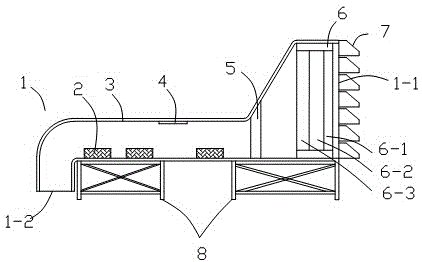

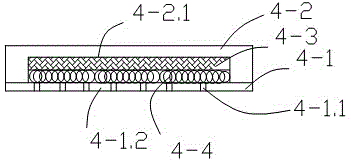

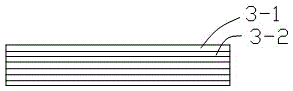

[0024] Such as Figures 1 to 3 As shown, a noise-reducing gas turbine intake system for low-temperature environments includes an intake body 1, the intake body 1 is a tubular structure, and the intake body 1 is provided with an insulation layer 3 along the inner wall. The insulation layer 3 is composed of several glass fiber layers 3-1 and aluminum foil layers 3-2. The air intake body 1 includes an air inlet 1-1 and an air outlet 1-2. The air inlet 1-1 is provided with There are several air intake pipes 7, and the interior of the air intake body 1 is provided with a multi-stage filter 6 near the air inlet 1-1, and the inner wall of the air intake body 1 is provided with a plurality of sound-absorbing plates 4, and the sound-absorbing plates 4 Including the inner board 4-1 and the outer board 4-2, the surface of the outer board 4-2 close to the inner board 4-1 is provided with a groove 4-2.1, and the groove 4-2.1 is provided with The sound-absorbing rock wool layer 4-3 and the...

Embodiment 2

[0030] Such as Figures 1 to 3 As shown, a noise-reducing gas turbine intake system for low-temperature environments includes an intake body 1, the intake body 1 is a tubular structure, and the intake body 1 is provided with an insulation layer 3 along the inner wall. The insulation layer 3 is composed of several glass fiber layers 3-1 and aluminum foil layers 3-2. The air intake body 1 includes an air inlet 1-1 and an air outlet 1-2. The air inlet 1-1 is provided with There are several air intake pipes 7, and the interior of the air intake body 1 is provided with a multi-stage filter 6 near the air inlet 1-1, and the inner wall of the air intake body 1 is provided with a plurality of sound-absorbing plates 4, and the sound-absorbing plates 4 Including the inner board 4-1 and the outer board 4-2, the surface of the outer board 4-2 close to the inner board 4-1 is provided with a groove 4-2.1, and the groove 4-2.1 is provided with The sound-absorbing rock wool layer 4-3 and the...

Embodiment 3

[0034] Such as Figures 1 to 3 As shown, a noise-reducing gas turbine intake system for low-temperature environments includes an intake body 1, the intake body 1 is a tubular structure, and the intake body 1 is provided with an insulation layer 3 along the inner wall. The insulation layer 3 is composed of several glass fiber layers 3-1 and aluminum foil layers 3-2. The air intake body 1 includes an air inlet 1-1 and an air outlet 1-2. The air inlet 1-1 is provided with There are several air intake pipes 7, and the interior of the air intake body 1 is provided with a multi-stage filter 6 near the air inlet 1-1, and the inner wall of the air intake body 1 is provided with a plurality of sound-absorbing plates 4, and the sound-absorbing plates 4 Including the inner board 4-1 and the outer board 4-2, the surface of the outer board 4-2 close to the inner board 4-1 is provided with a groove 4-2.1, and the groove 4-2.1 is provided with The sound-absorbing rock wool layer 4-3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com