A regional reinforcement drilling hole layout and hole forming method

A technology for reinforcing holes and arranging holes, which is applied in drilling equipment and methods, drilling equipment, and earth-moving drilling, etc., can solve problems such as caving and easy deformation of hole walls, and achieve the effects of low cost, reduced hole sealing time, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

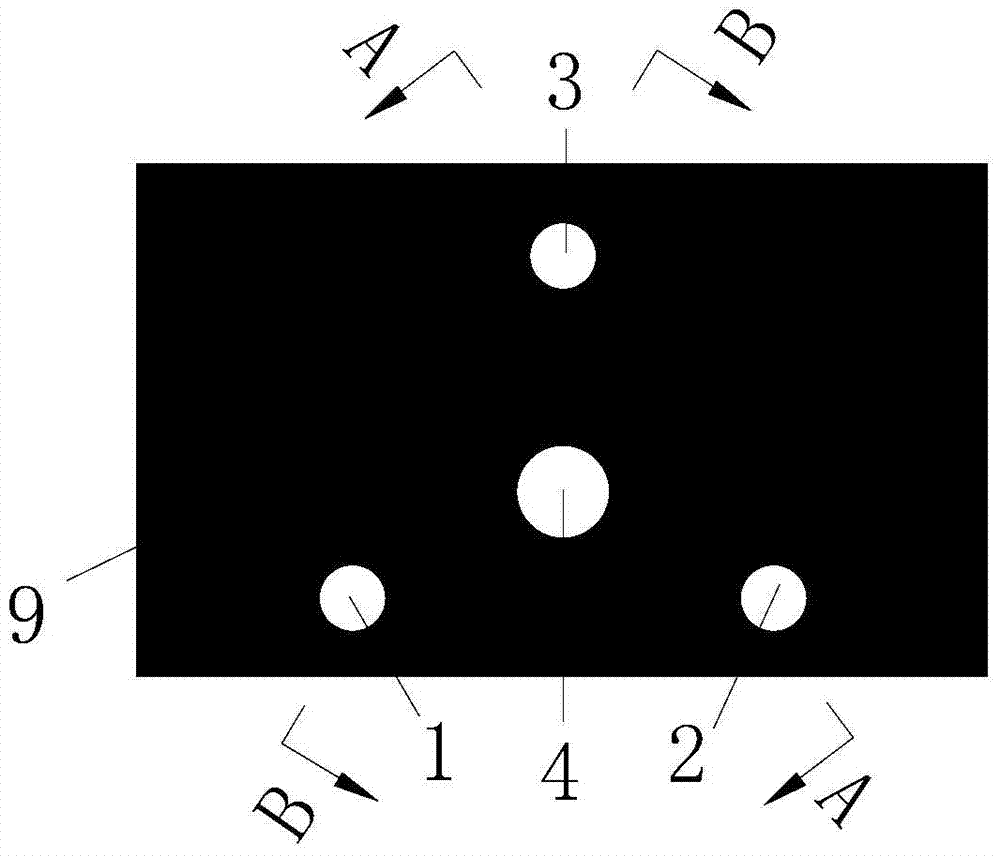

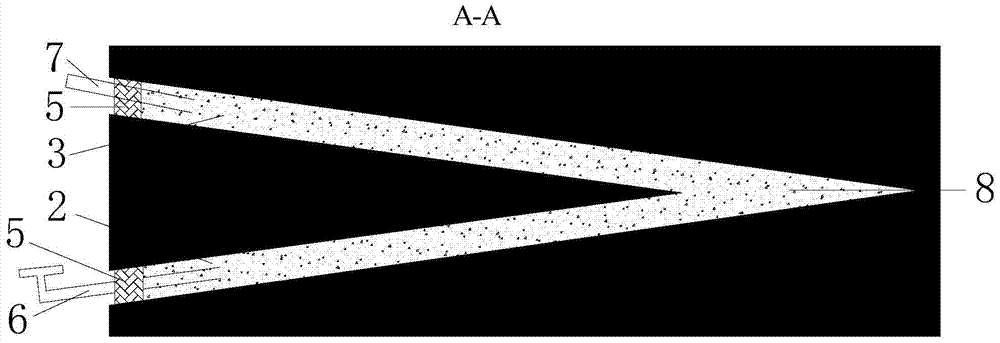

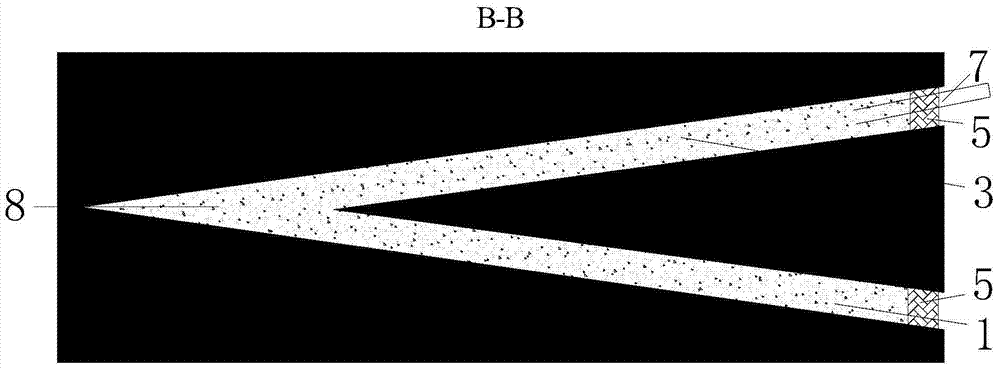

[0021] Firstly, reinforcement hole 1, reinforcement hole 2, and reinforcement hole 3 are sequentially constructed on the side of coal seam roadway 9, and the opening positions of reinforcement hole 1, reinforcement hole 2, and reinforcement hole 3 are respectively arranged in an equilateral triangle with a side length of 3-4m. At the three vertices; the final hole positions of reinforcement hole 1, reinforcement hole 2, and reinforcement hole 3 meet at the centerline of an equilateral triangle to form an equilateral triangle as the base, with reinforcement hole 1, reinforcement hole 2, and reinforcement hole 3 as The regular triangular pyramid shape of the edge makes the reinforcement hole 1, the reinforcement hole 2 and the reinforcement hole 3 run through in the coal seam. Drilling distance. Then, insert the grouting pipe 6 into the reinforceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com