Reinforced truss gypsum plate with insulation layer, novel dismantling-free formwork and their construction method

A technology of reinforced truss and free formwork, applied in the field of reinforced truss gypsum board, which can solve the problem of poor bonding and fixing of the main structure of the external thermal insulation layer of the external wall, frequent quality accidents of external thermal insulation of the external wall, and increased maintenance costs of housing construction To achieve the effect of facilitating quality control and inspection, eliminating hidden dangers in quality, and improving bonding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

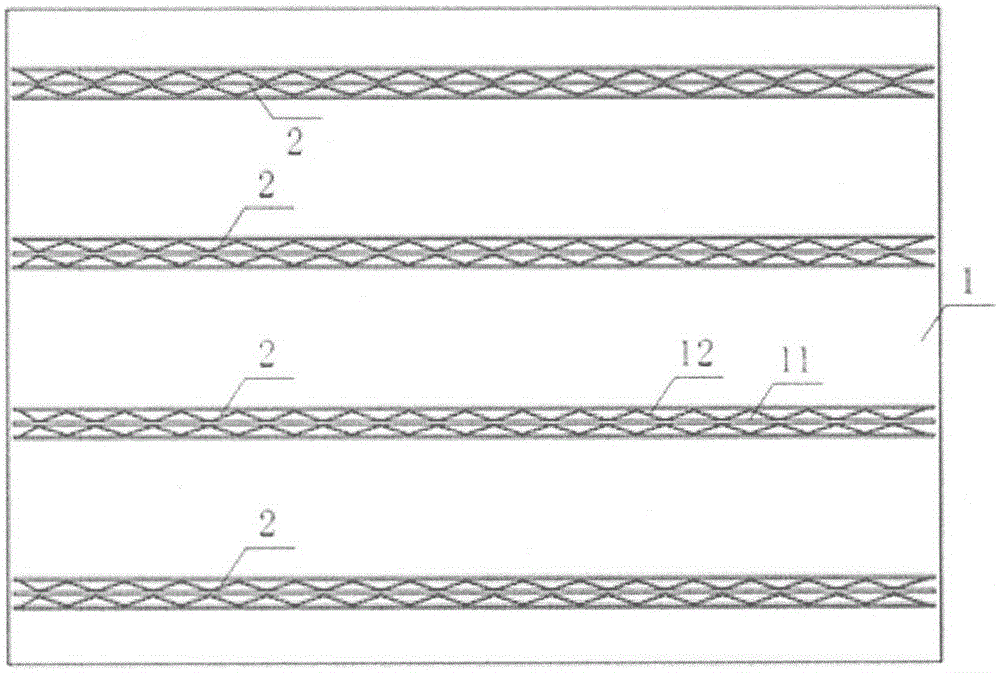

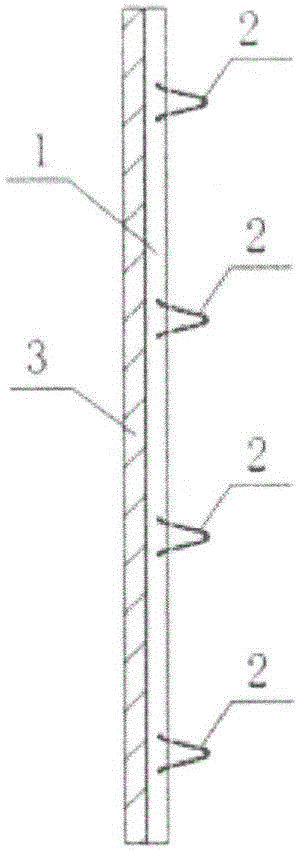

[0037] The invention can be used as a formwork for cast-in-place floor slabs of multi-storey or high-rise buildings. The construction process is as follows: the reinforced truss gypsum board with insulation layer and the new formwork without dismantling (hereinafter referred to as: gypsum formwork) are transported to the site and stored → the formwork support frame is erected → the gypsum formwork is hoisted → the gypsum formwork is installed → the steel bar binding and Pipeline laying → side formwork installation → acceptance → concrete pouring. So far, adopt the present invention as the cast-in-place floor slab of multi-storey or high-rise building permanently without removing formwork, pour reinforced concrete on it, after cast-in-place concrete is hardened, the reinforced truss gypsum board with insulation layer does not dismantle, and it and cast-in-place The floor slabs bear the external load together, thus becoming a part of the building's floor slab and having the func...

Embodiment 2

[0039] The present invention can be used as the external wall template of the cast-in-place wall body of multi-storey or high-rise buildings. The construction process is as follows: A reinforced truss gypsum board with insulation layer and a new formwork without dismantling (hereinafter referred to as: gypsum formwork) are transported to the site and stored → hoisting of gypsum formwork → temporary support installation of gypsum formwork → wall reinforcement binding and pipelines Laying→formwork installation on the other side of the wall→acceptance→wall concrete pouring. So far, adopt the present invention as the permanent dismantling-free formwork of the cast-in-place wall of multi-storey or high-rise buildings, pour concrete in the cavity formed by two formworks, after the cast-in-place concrete is hardened, the reinforced truss gypsum board with insulation layer is combined Without demolition, it bears the external load together with the cast-in-place wall, thus becoming a ...

Embodiment 3

[0041] The invention can be used as the bottom form of the prefabricated wall panels or prefabricated floor slabs of multi-storey or high-rise buildings. The construction process is as follows: A reinforced truss gypsum board with insulation layer and a new formwork without dismantling (hereinafter referred to as: gypsum formwork) are placed horizontally on the formwork of the factory → side formwork installation → steel bar binding and pipeline laying → acceptance → concrete Pouring→maintenance→solidification and forming→remove the side formwork. So far, the present invention is used as a permanent formwork for prefabricated walls or prefabricated floors of multi-storey or high-rise buildings. Concrete is poured on the base form. , it bears the external load together with the poured concrete, thus becoming a new prefabricated wall or prefabricated floor with insulation layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com