Connector used for connecting two objects and prefabricated member used for connector during connection

A technology of prefabricated components and prefabricated parts, which is applied in the direction of basic structure engineering, construction, sheet pile walls, etc. It can solve the problems of connection failure, easy detachment of enlarged parts, and small contact area, so as to prevent pull-off and plug-in The process is stable and reliable, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

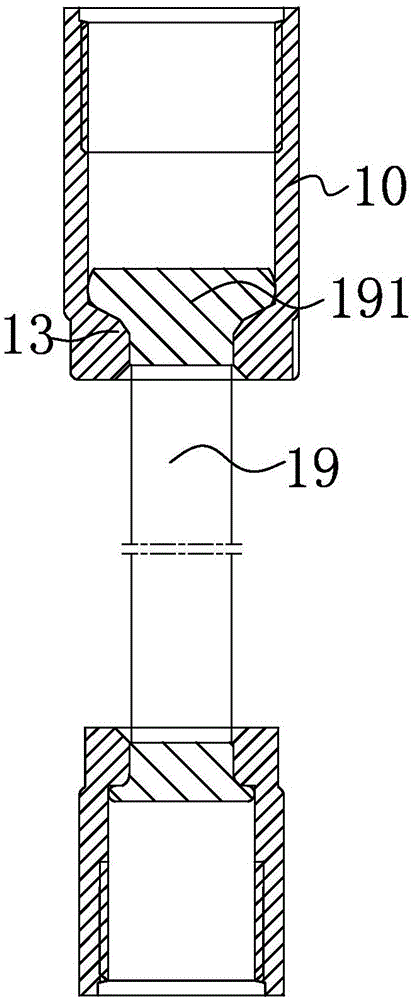

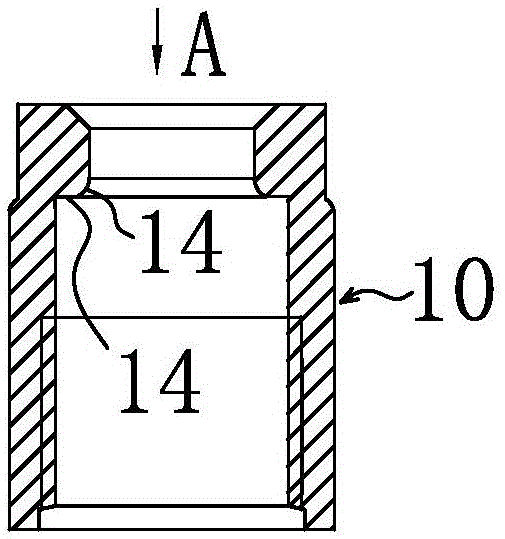

[0096] The present invention provides a connecting piece for connecting two objects, such as Figure 9 As shown, it includes two connecting nuts 10, one of which is screwed with a plug connector 20, and one end of the plug connector 20 is the plug body end 21, which has an external thread and is used for screwing and fixing the connecting nut 10. , the other end has a plug joint 22, and there is an annular slot 23 between the plug joint 22 and the plug main body end 21, and the other connecting nut 10 is screwed with an intermediate nut 30, and the middle nut 30 has a frustum-conical In the middle channel 301, the clamping platform 13 of the connecting nut 10 is provided with an elastic component 31 and a positioning snap ring 32 in sequence. When the connector 20 passes through the intermediate nut 30 and is inserted into the positioning snap ring 32, the positioning snap The ring 32 can clamp the plug connector 20 so as to connect the two connecting nuts 10 to each other.

...

Embodiment 2

[0121] Such as Figure 35 As shown, the present invention also provides a prefabricated component connected by the above-mentioned connector, the prefabricated component includes several independent and interconnected prefabricated parts 1, and at least two prefabricated parts 1 are connected by a connecting part . The prefabricated part 1 described in this embodiment is a prefabricated pile, such as a square pile, a cylinder, a hollow pile, a solid pile, a pile with a variable section, a pile with a constant section, and the like.

[0122] The specific way to connect with connectors is: Figure 34 and Figure 9 As shown, at least one one-to-one corresponding connecting nut 10 is respectively arranged at the ends of the two prefabricated parts 1, wherein the connecting nut 10 in one prefabricated part 1 is screwed with a plug connector 20, and the connecting nut 10 in the other prefabricated part 1 The connecting nut 10 is screwed with an intermediate nut 30, and the interm...

Embodiment 3

[0126] The structure and working principle of this embodiment and embodiment 2 are basically the same, the difference is that, as Figure 36 As shown, one end of the prefabricated part 1 has several connecting nuts 10 , and the other end has a connecting end plate 40 , and two adjacent prefabricated parts 1 are connected and fixed by connecting pieces or connecting end plates 40 .

[0127] Such as Figure 41 As shown, the connection end plate 40 has a tension hole mechanism 41 corresponding to the connection nut 10 one by one, and the tension hole mechanism 41 and the connection nut 10 are connected and fixed by a connection rod 19 . In the prior art, the connecting end plates 40 are connected by welding or bolted, so as to realize the connection between the two prefabricated parts 1 . Such as Figure 51 and Figure 52 As shown, the two connecting end plates 40 have an annular concave portion 40a at the connection interface, and the bottom of the concave portion 40a is weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com