Bottom argon blowing method capable of quickly homogenizing molten steel

A bottom blowing argon, uniform technology, applied in the field of metallurgical refining outside the furnace, can solve the problems of high smelting cost, long blowing time, large gas consumption, etc., and achieve the effects of improving smelting efficiency, shortening mixing time, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

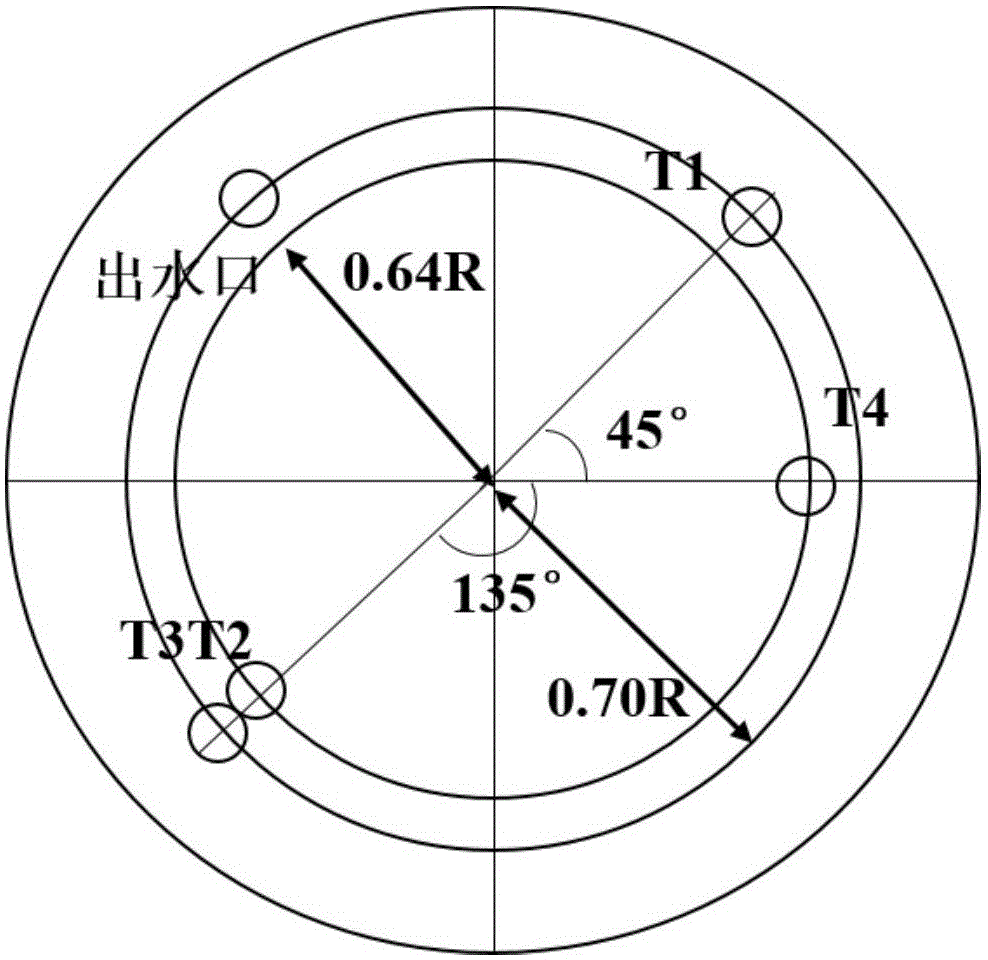

[0012] In the water simulation optimization study on the 120t steel ladle used for refining, the ladle bottom device such as figure 1 The breathable brick shown. Use T2-T4 combination to carry out one strong and one weak blowing, the angle between the two is 135°, located at 0.64R, T2 uses weak blowing 100L / min, T4 uses strong blowing 500-700L / min, under the same total flow rate The measured mixing time is about 40% shorter than that of the T1-T3 combination with the shortest mixing time in the same flow rate of the double holes. The included angle of the T1-T3 combination is 180°, which is located at 0.7R.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com