Barium-strontium-calcium descaling and plugging-removing agent for near wellbore zone and preparation method thereof

A near-well zone and plug-removing agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as inability to completely suppress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

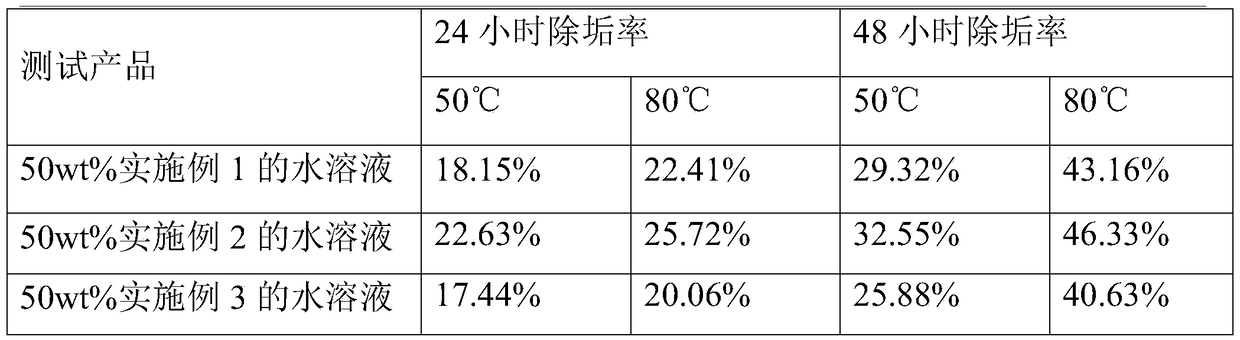

Examples

Embodiment 1

[0027] (1) Preparation of polyamine:

[0028] At room temperature, dissolve 50mL of triethylenetetramine in 50mL of water, slowly add 24.9g of epichlorohydrin dropwise in an ice-water bath with stirring, and control the reaction temperature at 5-30°C during the dropwise addition. After the addition, return to room temperature and continue stirring for 1 h, then raise the temperature to 60° C. and continue stirring for 4 h, stop heating, and cool to room temperature to obtain a polyamine intermediate;

[0029] (2) Preparation of polyamine carboxylate:

[0030] Dissolve 109g of chloroacetic acid into 218g of 2°C ice water, control the temperature in an ice-water bath, slowly add 154g of 30% sodium hydroxide solution to it while stirring, control the temperature of the reaction solution not to exceed 30°C, and react to obtain chlorine Sodium acetate solution was added to the polyamine solution obtained in step (1), stirred for 10 minutes, then the pH of the solution was adjusted...

Embodiment 2

[0034] (1) Preparation of polyamine:

[0035] At room temperature, dissolve 50mL of diethylenetriamine in 100mL of water, slowly add 40g of epichlorohydrin dropwise in an ice-water bath with stirring, and control the reaction temperature at 5-30°C during the dropwise addition, dropwise Return to room temperature and continue stirring for 1 h after completion, then raise the temperature to 60° C. and continue stirring for 5 h, stop heating, and cool to room temperature to obtain a polyamine intermediate;

[0036] (2) Preparation of polyamine carboxylate:

[0037] Dissolve 172g of chloroacetic acid into 344g of 2°C ice water, control the temperature in an ice-water bath, slowly add 242g of 30% sodium hydroxide solution to it while stirring, control the temperature of the reaction solution not to exceed 30°C, and react to obtain chlorine Sodium acetate solution was added to the polyamine solution obtained in step (1), stirred for 10 minutes, then the pH of the solution was adjus...

Embodiment 3

[0041] (1) Preparation of polyamine:

[0042] At room temperature, dissolve 50mL of diethylenetriamine in 100mL of water, slowly add 40g of epichlorohydrin dropwise in an ice-water bath with stirring, and control the reaction temperature at 5-30°C during the dropwise addition, dropwise Return to room temperature and continue stirring for 1 h after completion, then raise the temperature to 60° C. and continue stirring for 5 h, stop heating, and cool to room temperature to obtain a polyamine intermediate;

[0043] (2) Preparation of polyamine carboxylate:

[0044] Dissolve 108g of chloroacetic acid into 216g of 2°C ice water, control the temperature in an ice-water bath, slowly add 152g of 30% sodium hydroxide solution to it while stirring, control the temperature of the reaction solution not to exceed 30°C, and react to obtain chlorine Sodium acetate solution was added to the polyamine solution prepared in step (1), stirred for 10 minutes, then the pH of the solution was adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com