A kind of water-based coating that makes the surface of rubber boots matte and its preparation method

A technology of coating and rubber boots, which is applied in the field of water-based surface coating and its preparation, can solve problems affecting the health of employees, air pollution, fire and explosion, etc., and achieve good bonding fastness, good hydrolysis resistance, and elasticity excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

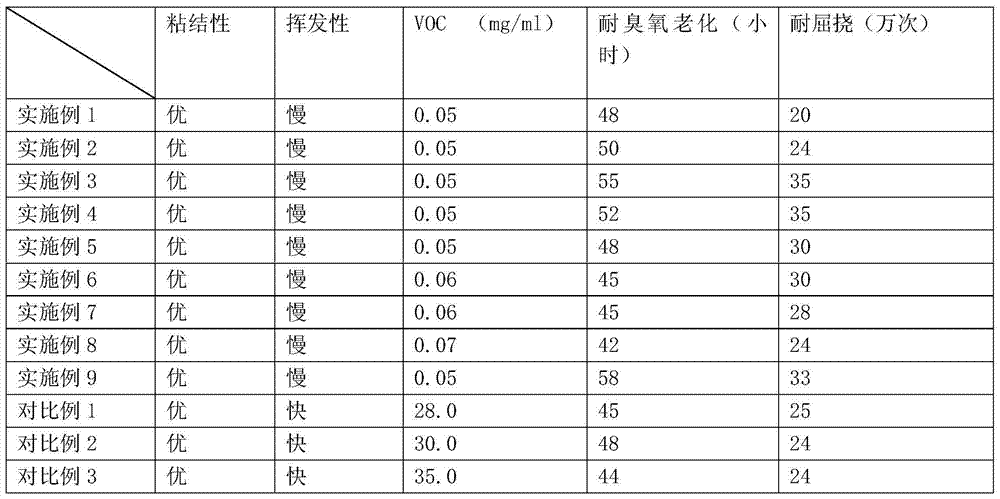

Examples

Embodiment 1

[0020] Embodiment 1: according to a kind of water-based surface treatment agent coating that makes the surface of rubber boots be a matte color according to the present invention, the water-based surface treatment agent coating is composed of the following components by weight percentage:

[0021] Silicone modified polyacrylate 43.0%;

[0022] Surfactant: Polycaprolactone 0.04%

[0023] Leveling agent: Silicone BYC333 0.03%

[0024] Water-based defoamer: TEGO Foamex 825 0.30%

[0025] Polymer dispersant: polycaprolactone-polyethyleneimine copolymer 0.25%

[0026] The balance is deionized water.

Embodiment 2

[0027] Embodiment 2: According to a kind of water-based surface treatment agent coating that makes the surface of rubber boots matte according to the present invention, preferably, the water-based surface treatment agent coating is composed of the following components by weight percentage :

[0028] Silicone modified polyacrylate 45.0%;

[0029] Surfactant: Polycaprolactone 0.04%

[0030] Leveling agent: Silicone BYC333 0.03%

[0031] Water-based defoamer: TEGO Foamex 825 0.30%

[0032] Polymer dispersant: polycaprolactone-polyethyleneimine copolymer 0.25%

[0033] The balance is deionized water.

Embodiment 3

[0034] Embodiment 3: According to a kind of water-based surface treatment agent coating that makes the surface of rubber boots matte according to the present invention, preferably, the water-based surface treatment agent coating is composed of the following components by weight percentage :

[0035] Silicone modified polyacrylate 47.0%;

[0036] Surfactant: Polycaprolactone 0.04%

[0037] Leveling agent: Silicone BYC333 0.03%

[0038] Water-based defoamer: TEGO Foamex 825 0.30%

[0039] Polymer dispersant: polycaprolactone-polyethyleneimine copolymer 0.25%

[0040] The balance is deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com