High performance soft magnetic ferrite material and preparation method thereof

A soft ferrite, high-performance technology, applied in the field of high-performance soft ferrite materials and preparation, can solve problems such as inability to guarantee conformity to products, and achieve the effects of enhanced comprehensive performance, enhanced crystal uniformity, and unique high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

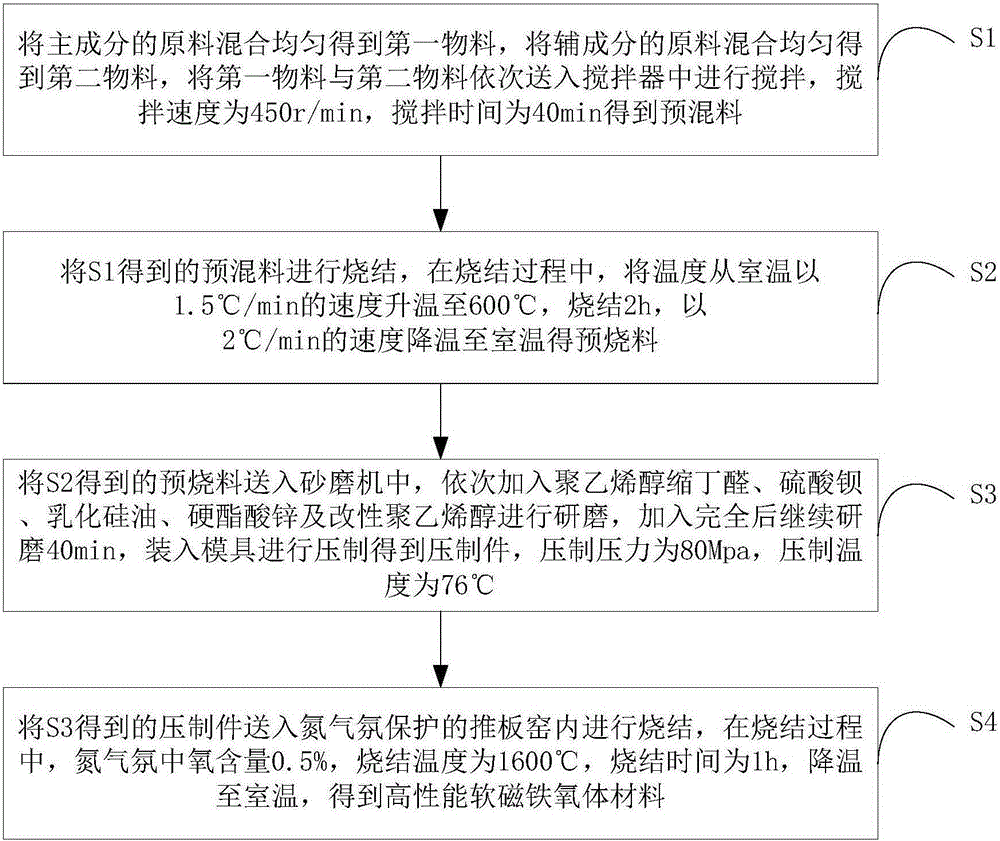

Method used

Image

Examples

Embodiment 1

[0024] A high-performance soft magnetic ferrite material, the raw materials of which include 100 parts by weight of main components, 0.001-0.003 parts of auxiliary components, and 1-5 parts of auxiliary agents;

[0025] The raw materials of the main component include: Fe 3 o 4 40 parts, 20 parts of NiO, 15 parts of ZnO, 3 parts of CuO, MnO 2 5 copies, WO 3 2 copies;

[0026] The raw materials of auxiliary components include by weight: Nb 2 o 5 0.5 parts, SiO 2 2 copies, Co. 2 o 3 0.5 parts, Ti 2 o 3 1.5 servings, La 2 o 3 1 part, 2.5 parts of chromium boride;

[0027] The raw materials of the auxiliary agents include 100 parts of modified polyvinyl alcohol, 3 parts of polyvinyl butyral, 3 parts of barium sulfate, 0.5 parts of emulsified silicone oil and 3 parts of zinc stearate.

[0028] During the preparation of modified polyvinyl alcohol, add 10 parts of polyvinyl alcohol, 2 parts of maleic anhydride, 20 parts of xylene, and 0.006 parts of butyric acid into a th...

Embodiment 2

[0030] A high-performance soft magnetic ferrite material, its raw materials include 100 parts by weight of main components, 0.003 parts of auxiliary components, and 1 part of auxiliary agents;

[0031] The raw materials of the main component include: Fe 3 o 4 50 parts, 16 parts of NiO, 20 parts of ZnO, 1 part of CuO, MnO 2 10 copies, WO 3 1 copy;

[0032] The raw materials of auxiliary components include by weight: Nb 2 o 5 2 parts, SiO2 1 copy, Co. 2 o 3 1.5 parts, Ti 2 o 3 0.5 parts, La 2 o 3 3 parts, 1.5 parts of chromium boride;

[0033] The raw materials of the auxiliary agents include 100 parts of modified polyvinyl alcohol, 6 parts of polyvinyl butyral, 1 part of barium sulfate, 1.5 parts of emulsified silicone oil and 1 part of zinc stearate.

[0034] During the preparation of modified polyvinyl alcohol, add 30 parts of polyvinyl alcohol, 1 part of maleic anhydride, 40 parts of xylene, and 0.005 parts of butyric acid into a three-necked flask, stir at reflu...

Embodiment 3

[0036] A high-performance soft magnetic ferrite material, the raw material includes 100 parts by weight of the main component, 0.0015 parts of the auxiliary component, and 4 parts of the auxiliary agent;

[0037] The raw materials of the main component include: Fe 3 o 4 42 parts, NiO18.5 parts, ZnO16 parts, CuO2.4 parts, MnO 2 6 copies, WO 3 1.4 copies;

[0038] The raw materials of auxiliary components include by weight: Nb 2 o 5 0.8 parts, SiO 2 1.6 parts, Co. 2 o 3 1 part, Ti 2 o 3 1 serving, La 2 o 3 1.5 parts, 2.3 parts of chromium boride;

[0039] The raw materials of the auxiliary agents include, by weight, 100 parts of modified polyvinyl alcohol, 4 parts of polyvinyl butyral, 2.3 parts of barium sulfate, 0.8 parts of emulsified silicone oil, and 1.8 parts of zinc stearate.

[0040] During the preparation of modified polyvinyl alcohol, 20 parts of polyvinyl alcohol, 1.2 parts of maleic anhydride, 30 parts of xylene, and 0.0058 parts of butyric acid were add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com