Sea sand desalination treatment technique and system

A treatment process and treatment system technology, which is applied in the field of sea sand desalination treatment system, can solve the problems of sea sand failing to meet building needs, large amount of fresh water, etc., and achieve the effect of good dechlorination effect, low cost and saving fresh water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

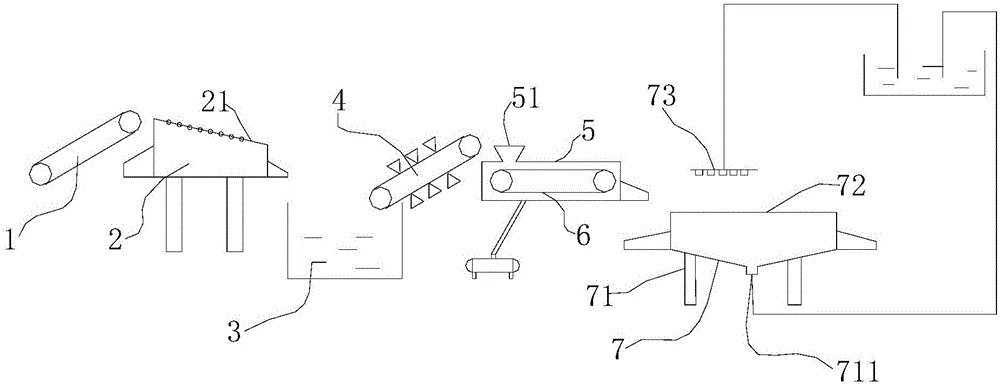

[0028] figure 1 It schematically shows the structure of a seawater desalination treatment system according to an embodiment of the present invention.

[0029] Such as figure 1 As shown, a seawater desalination treatment system includes, from left to right, a first transmission device 1, a vibrating sand screen machine 2, a dechlorination tank 3, a bucket elevator 4, a sealing device 5, a second transmission device 6 and a vibrating jet Washing device7.

[0030] Such as figure 1 As shown, the first conveying device 1 is a belt conveyor or other devices (such as automatic grippers, etc.), the first conveying device 1 is placed obliquely, the inlet of the first conveying device 1 is located below the sea sand funnel, and the outlet is located It is connected with the sand vibrating screen machine 2, and the sea sand can reach the san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com